Liquid crystal display module

A liquid crystal display module and display surface technology, which is applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of not being able to use a large color filter glass substrate 201, not conforming to the design trend of the display's narrow frame 100, and limited size, etc. The effect of reducing the risk of surrounding light leakage and improving the display quality of the picture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

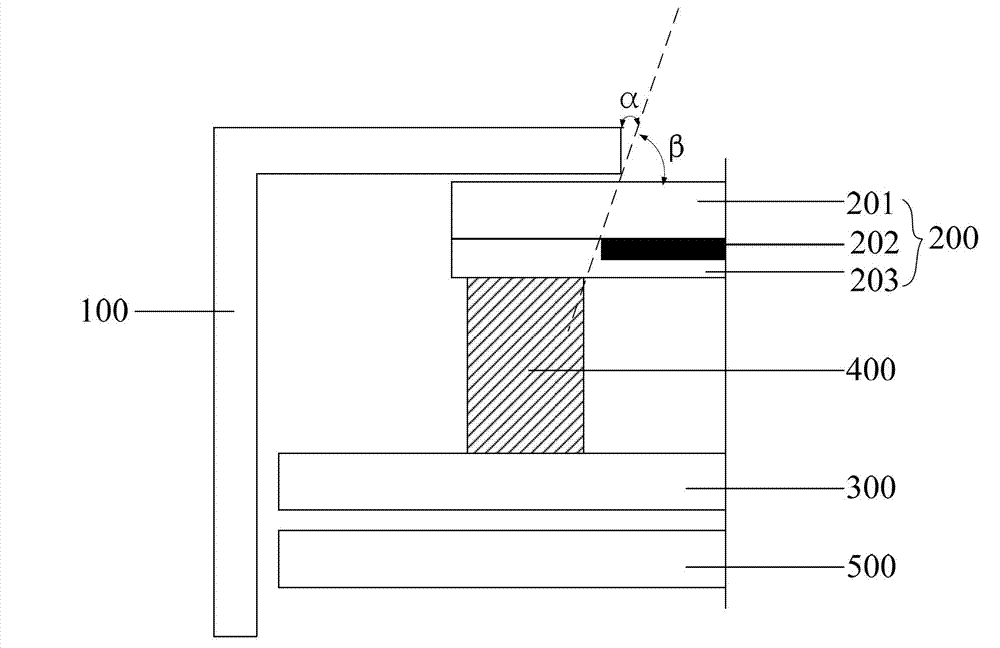

[0061] Such as Figure 5 Shown is a schematic diagram of the surrounding structure of the liquid crystal display module according to the first embodiment of the present invention, where only the array glass substrate 301 forming the array substrate 300 and the metal forming the light-shielding layer 302 are shown in the figure. signal lines, while other layers forming the array substrate 300 are not shown.

[0062] Such as Figure 5 As shown, in this embodiment, the liquid crystal display module includes a liquid crystal panel and a frame 100 arranged around the liquid crystal panel, wherein the liquid crystal panel includes a color filter substrate 200 and an array substrate 300 arranged in opposite boxes, wherein The color filter substrate 200 includes a color filter glass substrate 201, a black matrix 202 formed at a position close to the edge of the color filter glass substrate 201, and a common electrode 203 covering the black matrix 202 (for forming Other components of...

Embodiment 2

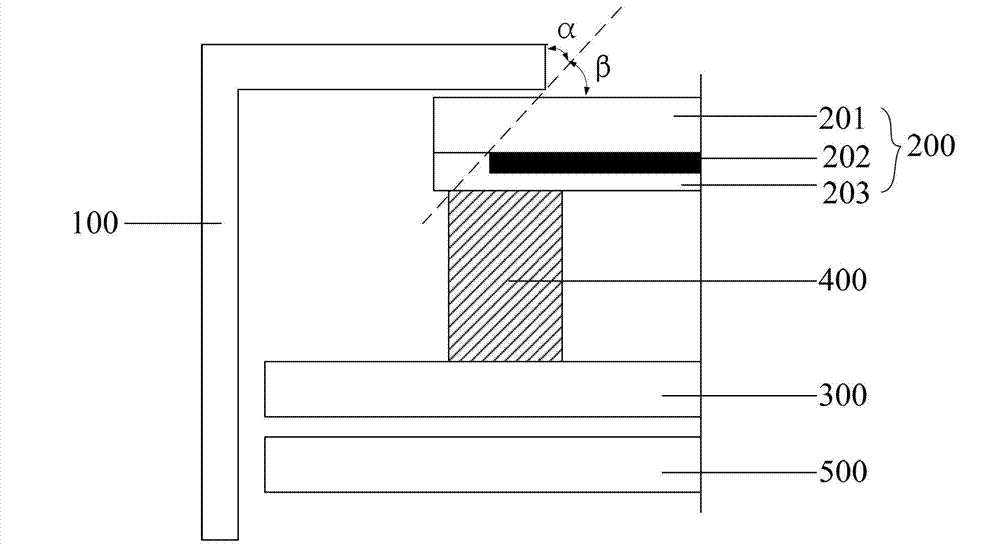

[0067] Such as Figure 6 Shown is a schematic diagram of the peripheral structure of the liquid crystal display module according to the second embodiment of the present invention, in which only the array glass substrate 301 forming the array substrate 300 and the metal signal forming the light-shielding layer are shown in the figure. lines, while other layers forming the array substrate 300 are not shown.

[0068] Such as Figure 6 As shown, in this embodiment, the liquid crystal display module includes a liquid crystal panel and a frame 100 arranged around the liquid crystal panel, wherein the liquid crystal panel includes a color filter substrate 200 and an array substrate 300 arranged in opposite boxes, wherein The color filter substrate 200 includes a color filter glass substrate 201, a black matrix 202 formed at a position close to the edge of the color filter glass substrate 201, and a common electrode 203 covering the black matrix 202 (for forming Other components of ...

Embodiment 3

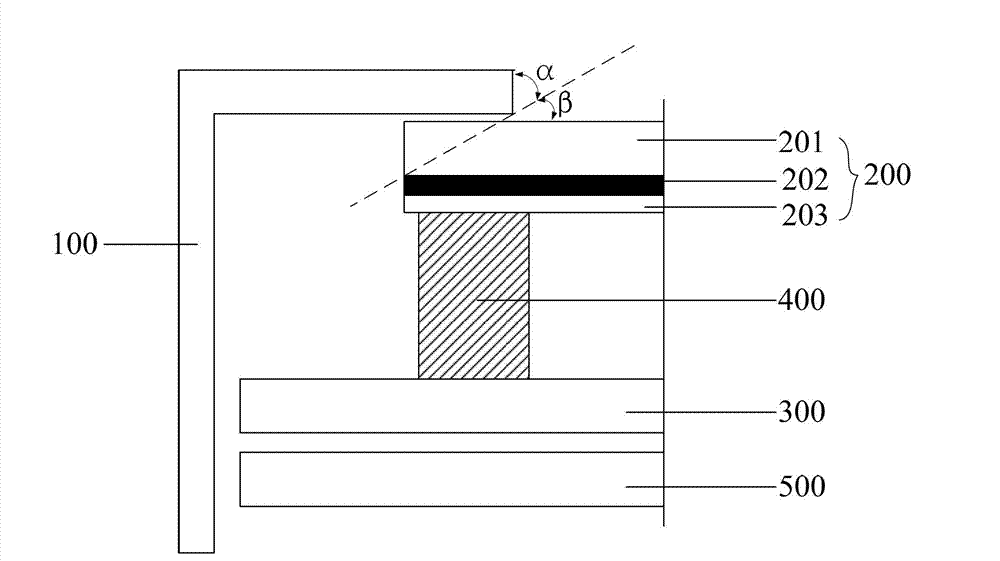

[0073] The light shielding in the liquid crystal display module in this embodiment is formed by cooperation of the second gate lines 304 and the second data lines 305 .

[0074] Such as Figure 7 Shown is a schematic diagram of the peripheral structure of the liquid crystal display module according to the second embodiment of the present invention, in which only the array glass substrate 301 forming the array substrate 300 and the metal signal forming the light-shielding layer are shown in the figure. lines, while other layers forming the array substrate 300 are not shown.

[0075] Such as Figure 7As shown, in this embodiment, the liquid crystal display module includes a liquid crystal panel and a frame 100 arranged around the liquid crystal panel, wherein the liquid crystal panel includes a color filter substrate 200 and an array substrate 300 arranged in opposite boxes, wherein The color filter substrate 200 includes a color filter glass substrate 201, a black matrix 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com