Spring pin assembling clamp

A technology for assembling fixtures and elastic pins, which is applied to hand-held tools, manufacturing tools, workpiece clamping devices, etc., can solve the problems of time-consuming, easily lost parts, etc., and achieve the effects of simple operation, safe assembly, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

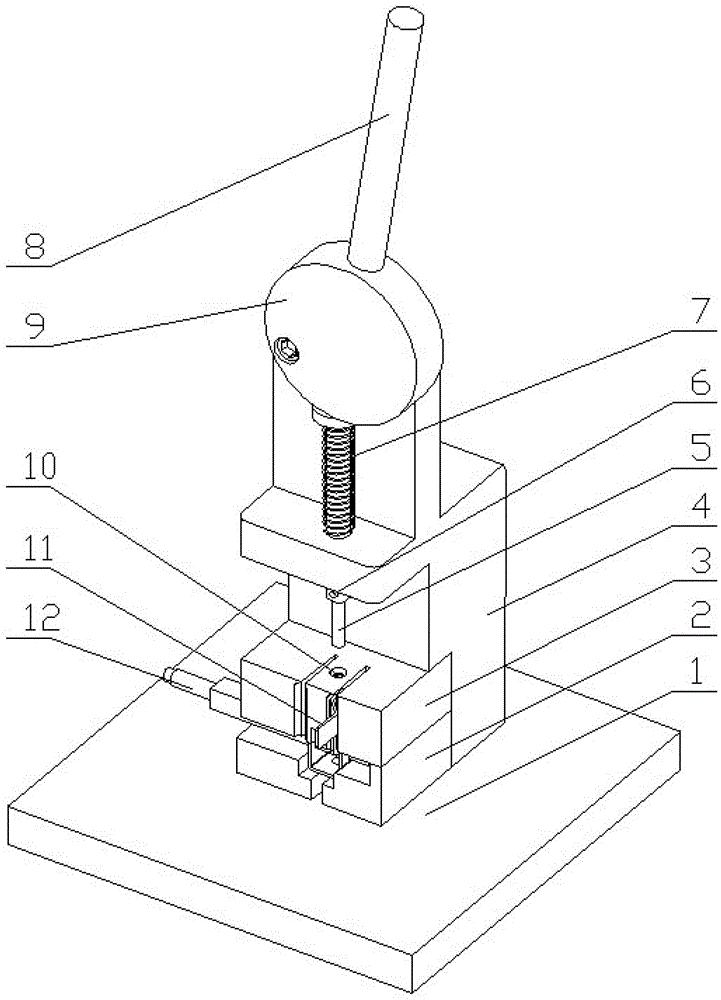

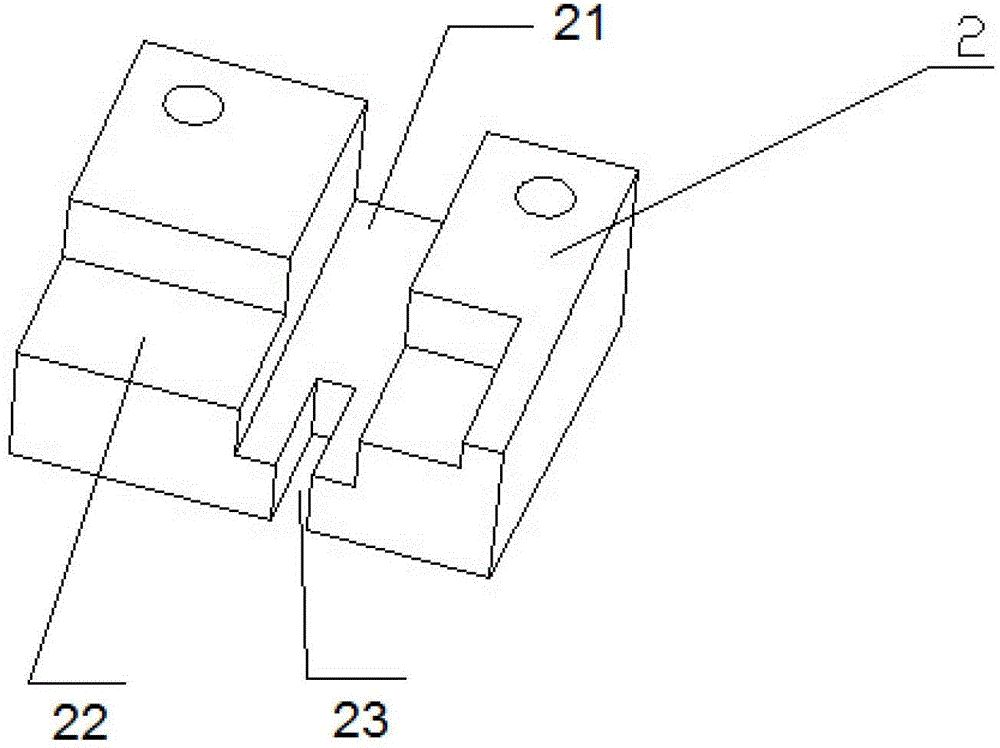

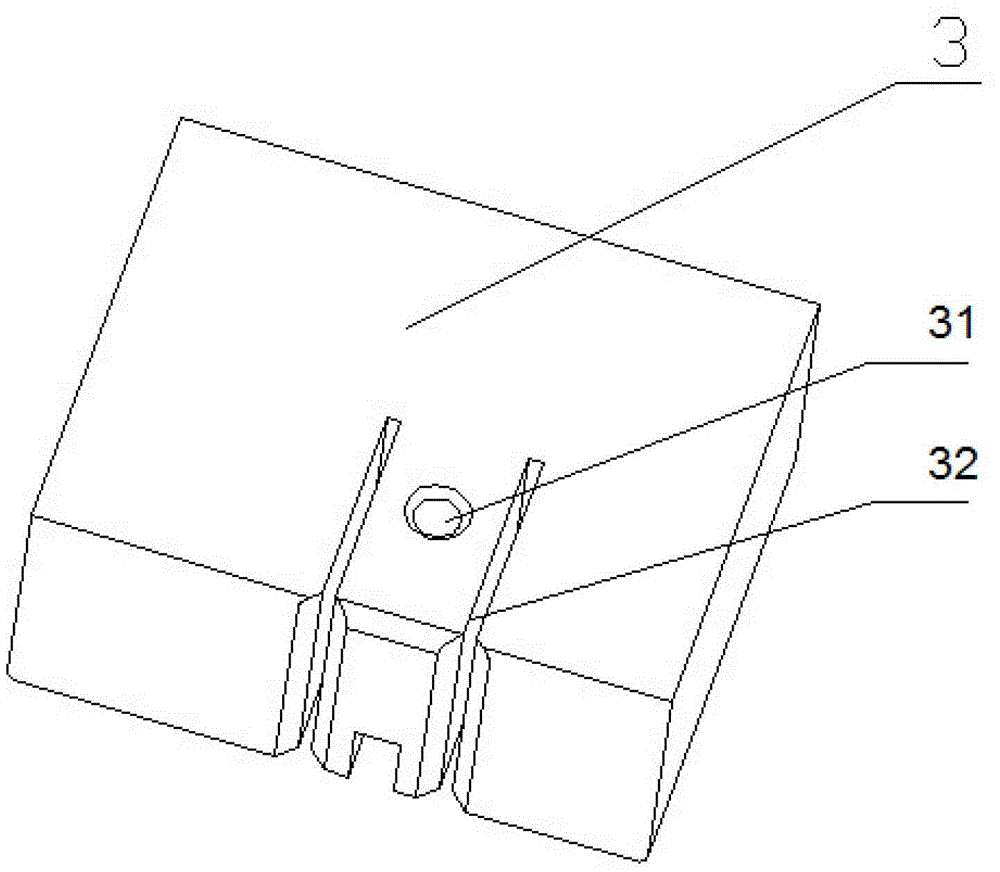

[0017] figure 1 and Figure 4 It is a structural diagram of an elastic pin assembly fixture of the present invention, including a base 1, and a backing plate 2 and a pressure plate 3 for positioning the guide plate 11 and the square shaft 12, the guide plate 11 and the square shaft 12 are located between the backing plate 2 and the Between the pressure plates 3, the backing plate 2 is fixedly connected with the base 1; the base 1 is provided with a support 4, and the support 4 is provided with a push rod 5, and the push rod 5 can slide on the support 4; The through hole 31 of the elastic pin 10, the through hole 31 and the hole on the square shaft 12 and the hole on the guide plate 11 are on the same axis;

[0018] The operating mechanism includes an eccentric wheel 9, which is located on the support 4 and can rotate on the support 4. The eccentric wheel 9 is in contact with one end of the push rod 5, and the eccentric wheel 9 is provided with a handle 8. The operating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com