A kind of improver for deep desulfurization of phosphorus iron ring

A phosphorus iron ring and deep desulfurization technology, which is applied in the field of metal smelting and raw material preparation, can solve the problems of high alkalinity, easy corrosion of furnace lining and high cost of desulfurizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

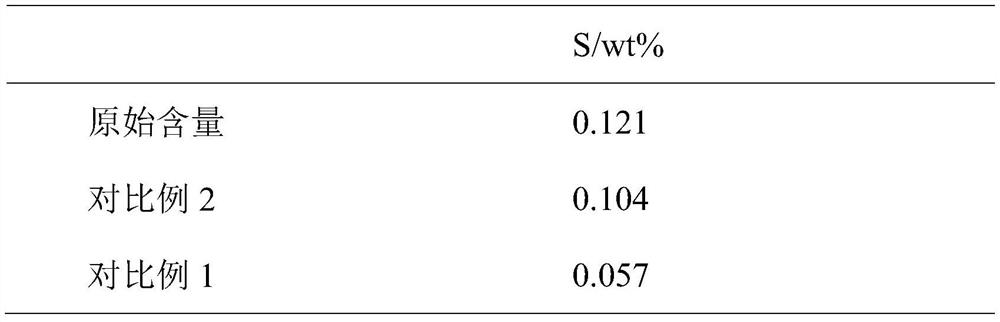

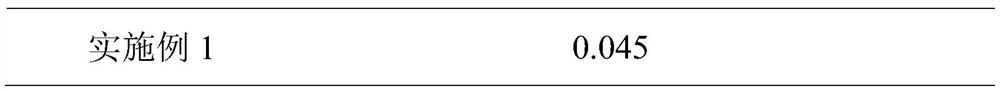

Embodiment 1

[0029] In this embodiment, a medium-frequency induction furnace is used, and the element content of the initial waste phosphorus iron ring in this embodiment is 0.121wt%. The dosage of the phosphor iron ring is 450kg, and the ratio of deep desulfurization improver is: 70wt% of cerite and 30wt% of apatite. The addition amount of the phosphorus iron ring deep desulfurization improver is 2.0wt%.

[0030] Melt 450kg of waste iron rings in an induction furnace with a melting temperature of 1430°C. Melt the waste iron rings into a liquid state, and add a deep desulfurization improver for iron rings into the induction furnace. After the improver is melted to liquid, it is refined for 8 minutes, and the slag is removed and released from the furnace. Increase the temperature of the induction furnace to the temperature of the furnace: 1500°C. The improved phosphorus iron ring molten iron is obtained. Sampling was taken to determine the content of phosphorus iron ring elements after re...

Embodiment 2

[0041] Using a medium-frequency induction furnace, the initial low-sulfur phosphorus iron ring element content is as follows, S: 0.097wt%. The amount of the ferrophosphorus ring is 450kg, and the ratio of the deep desulfurization improver for the ferrophosphorus ring is: 80wt% of cerite and 20wt% of apatite. The amount of the deep desulfurization improver for the phosphorus iron ring is 3wt% of that of the phosphorus iron ring. After the iron-phosphorus ring is melted in an induction furnace, a deep desulfurization improver for the iron-phosphorus ring is added, and after 10 minutes of complete melting, it is taken out of the furnace, and samples are taken to determine the element content of the iron-phosphorus ring after refining, S: 0.032wt%.

Embodiment 3

[0043] Using a medium-frequency induction furnace, the initial low-sulfur phosphorus iron ring element content is as follows, S: 0.088wt%. The amount of phosphorus iron ring is 450kg, and the ratio of the phosphorus iron ring deep desulfurization improver is: allanite 75wt%, apatite: 25wt%. The amount of the deep desulfurization improver for the phosphorus iron ring is 1wt% of that of the phosphorus iron ring. After the iron-phosphorus ring is melted in an induction furnace, a deep desulfurization improver for the iron-phosphorus ring is added, and it is released from the furnace 10 minutes after complete melting. Sampling is taken to determine the element content of the iron-phosphorus ring after refining, S: 0.020wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com