Positioning local holographic IMR membrane

A holographic and local technology, applied in the field of IMR film, can solve the problems of low product differentiation, IMR film can not meet market demand, single function, etc., to achieve the effect of enhancing product differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

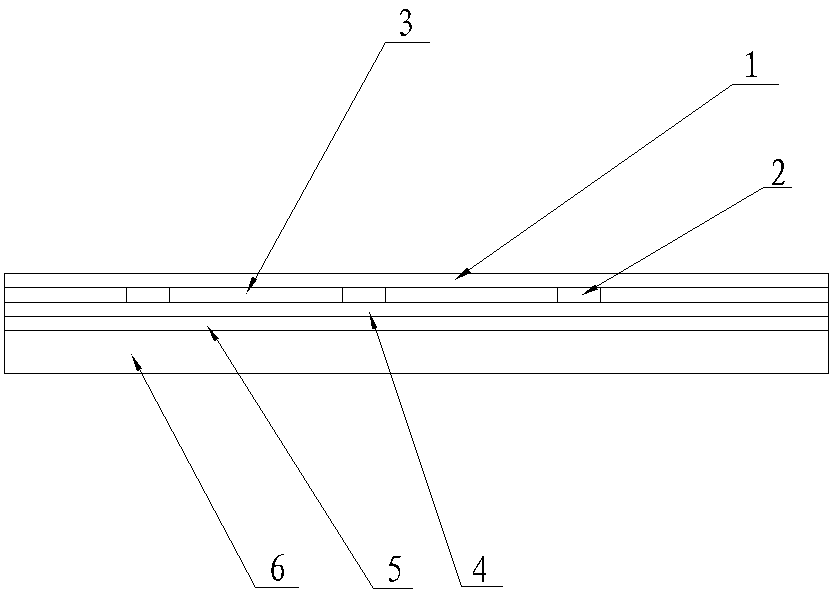

[0014] refer to figure 1 , the present invention is a positioning partial holographic IMR film, comprising a hot melt adhesive layer 1, a partial holographic layer 2, an ink printing layer 3, a resin protective layer 4, a release layer 5 and a plastic film layer 6, and the release layer 5 is applied on On the plastic film layer 6, the resin protective layer 4 is coated on the release layer 5, the ink printing layer 3 is printed on the resin protective layer 4, the local holographic layer 2 is loaded in the ink printing layer 3, and the hot melt adhesive layer 1 is coated On ink print layer 2.

[0015] The release layer 5 is applied on the plastic film layer 6, which is in a solid state at normal temperature, and its viscosity becomes smaller at a certain temperature, and the plastic film layer 6 can be peeled off quickly, and the resin protective layer 4 is coated on the release layer 5 Above, the ink printed layer 3 and the partial holographic layer 2 can be protected, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com