Material mistake bag rejection device and method

A technology for removing devices and materials, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as prone to malfunction, easy to produce empty packages and continuous packages, and affect secondary packaging of materials, achieving short action cycle, The effect of low cost and high action accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

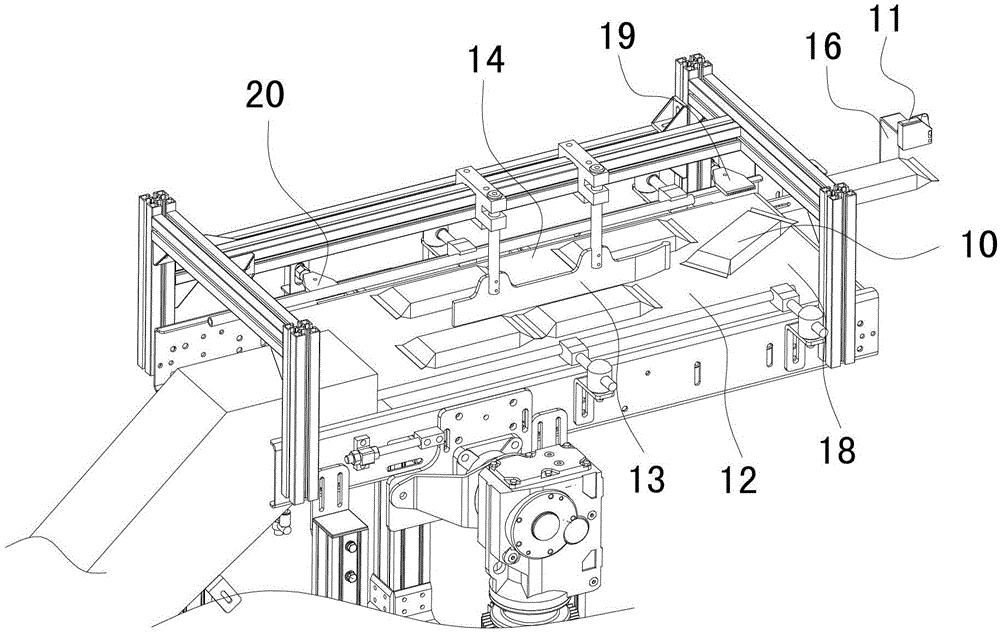

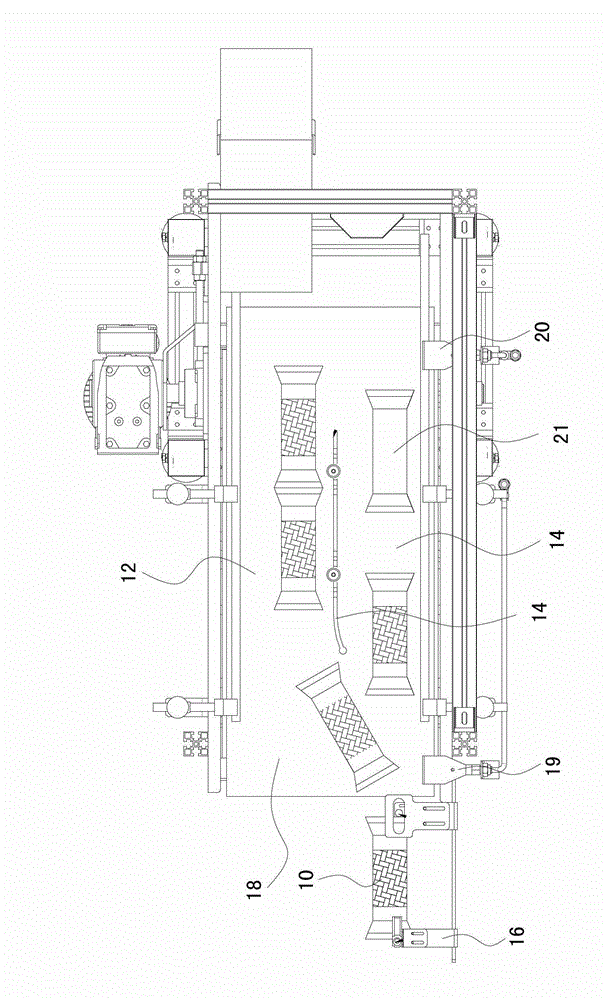

[0024] like figure 1 and figure 2 As shown, the material wrong package rejecting device of the present invention includes a pair of continuous package sensing devices 11, a rejecting device, adjacently disposed rejecting passages 12 and feeding passages 14, and a control device. Both the connected bag sensing device 11 and the rejecting device are connected to the control device, the connected bag sensing device 11 is arranged at the front end of the feeding channel in the forward direction, and the distance between the connected bag sensing device 11 is Greater than the length of the material 10, the inlet of the rejecting channel 12 communicates with the inlet of the feeding channel 14, and the rejecting device is arranged on one side of the head end of the feeding channel 14 and connected to the inlet of the rejecting channel 12. relatively.

[0025] Take the application of the device for removing wrong packages of materials according to the present invention to pillow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com