Buffering support structure

A technology of supporting structure and cover plate, applied in the field of buffer structure, can solve the problems of reduced spring life, failure of buffer structure, etc., and achieve the effects of improving lubrication, slowing down falling speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

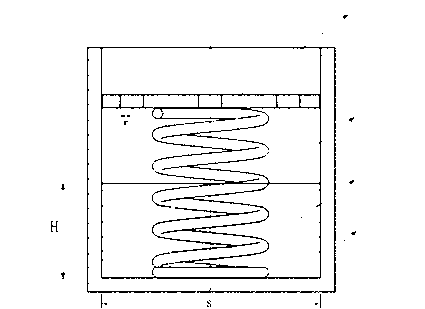

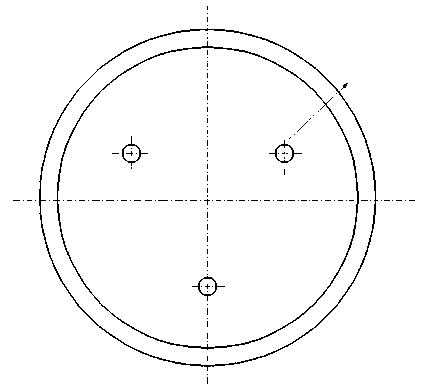

[0013] figure 1 , figure 2 The functions of each component are as follows:

[0014] Cover plate 1: it plays a supporting role under the action of spring 2; when spring 2 fails, it supports the transported vehicle under the action of lubricating oil 3. Spring 2: plays the role of cushioning and supporting; lubricating oil 3: lubricating cover plate 1 and cylinder body 4 to prolong the service life; when spring 2 fails, slow down the falling speed of the cover plate; cylinder body 4: load lubricating oil and spring.

[0015] The following combination figure 1 , figure 2 Illustrate the buffer support structure working method of the present invention:

[0016] The cover plate 1 is circular and has three overflow holes, which are symmetrical along the center of the circle. Take the aero-engine transport vehicle with strict requirements on the buffer support structure as an example. The buffer support structure is loaded on the transport vehicle. As the transport vehicle tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com