Part size measurement method based on charge coupled device (CCD)

A measurement method and part technology, applied in measurement devices, computer parts, instruments, etc., can solve the problems of high price, difficult to popularize, complex mechanical structure, etc., and achieve the effect of low cost, simple algorithm and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

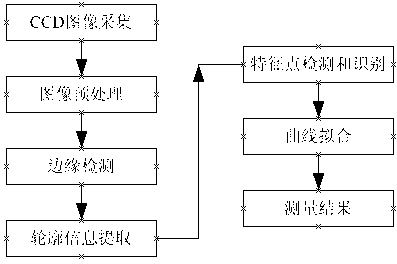

[0039] A kind of CCD-based part size measurement method proposed by the present invention will be described in detail below in conjunction with the flow chart shown in the accompanying drawings:

[0040] A kind of part dimension measurement method based on CCD, its specific implementation steps are as follows:

[0041] Step 1, Image Acquisition

[0042] Use the CCD camera to take the digital grayscale image of the surface of the part, and output it to the Gigabit Ethernet Network Card (Gigabit Ethernet Network Card) with the Gige standard video signal; Or stored digital image signals for processing and analysis. The image acquisition device adopted in the image acquisition step of the present invention includes a CCD camera, a light source, and a CCD camera controller; the light source used in the present invention is a back light source. The light source is composed of an LED rectangular box and a light-shielding metal cover. There are several LED light-emitting tubes in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com