Resonant cavity enhanced monolithic integrated sensor and measurement method

A single-chip integration and measurement method technology, applied in the field of integrated optics, can solve the problems of not realizing single-wavelength laser measurement of micro-ring resonators, limiting the application of micro-ring resonators, and difficult to achieve monolithic integration, etc., to achieve high-speed measurement and application. , the effect of large carrier mobility, high-speed measurement and sensing applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

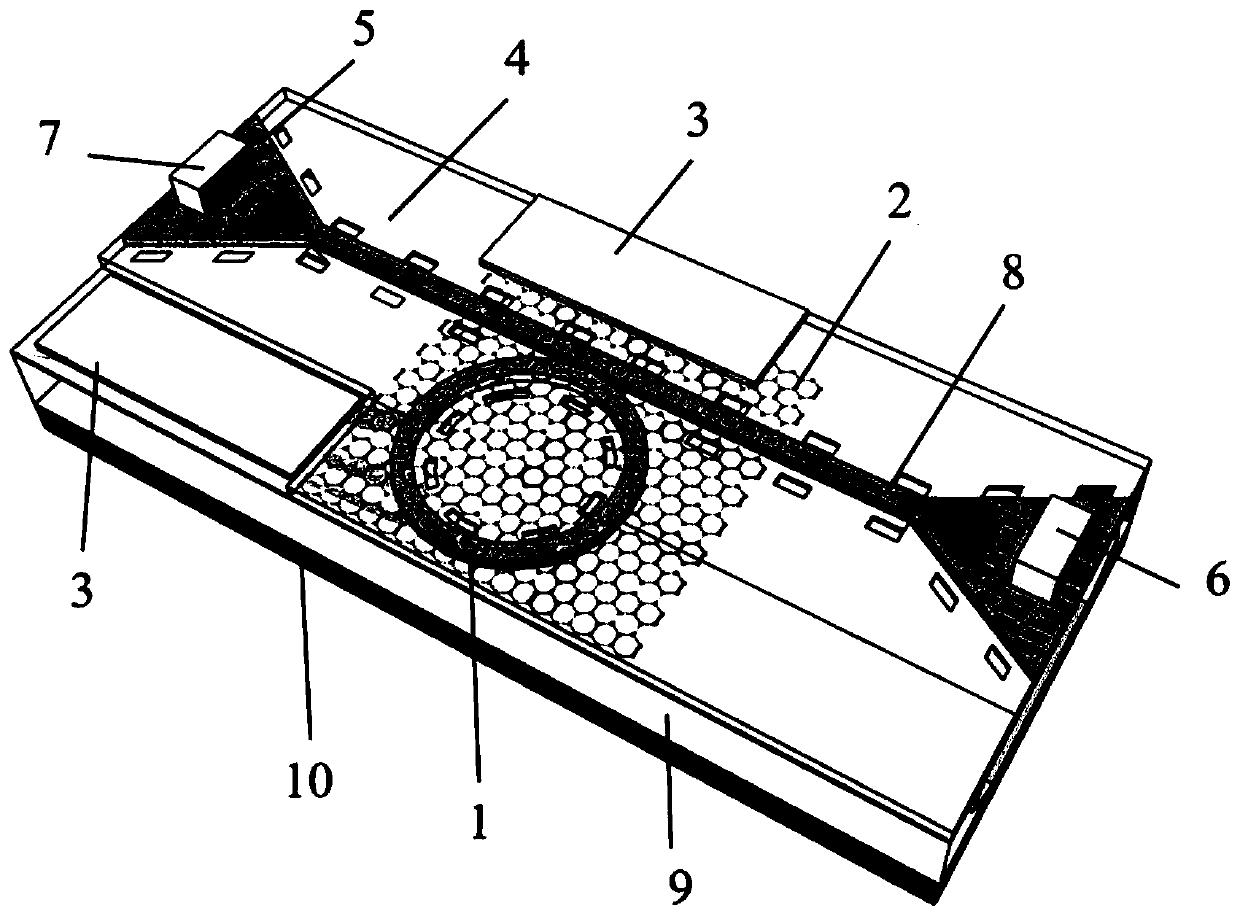

Embodiment 1

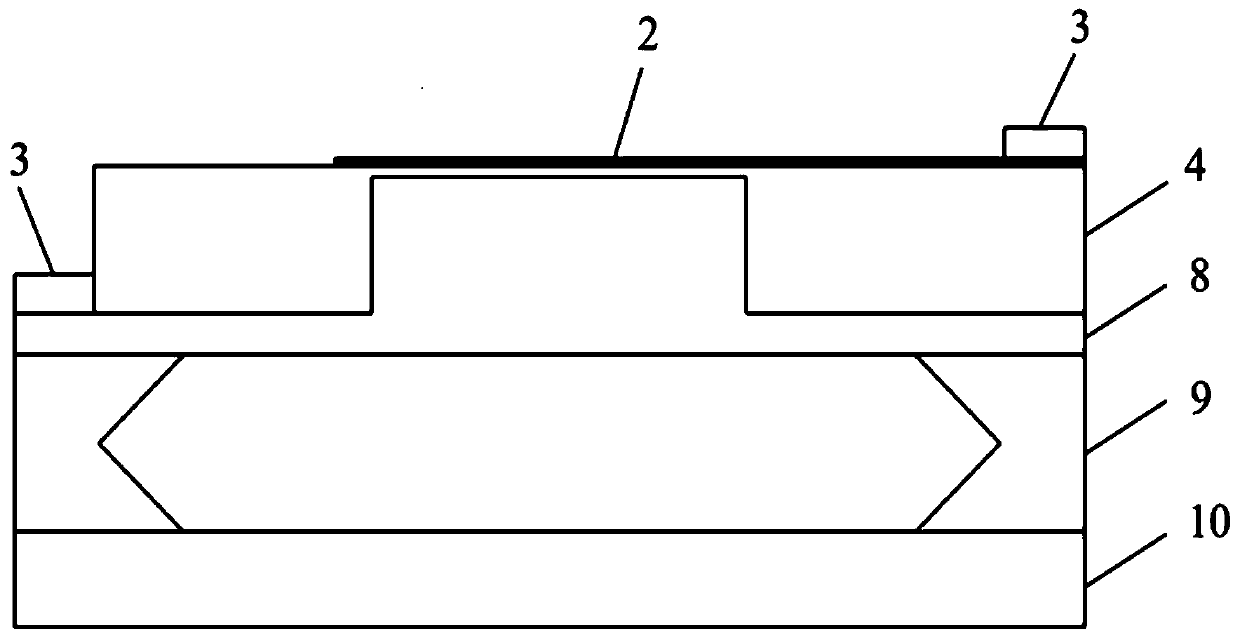

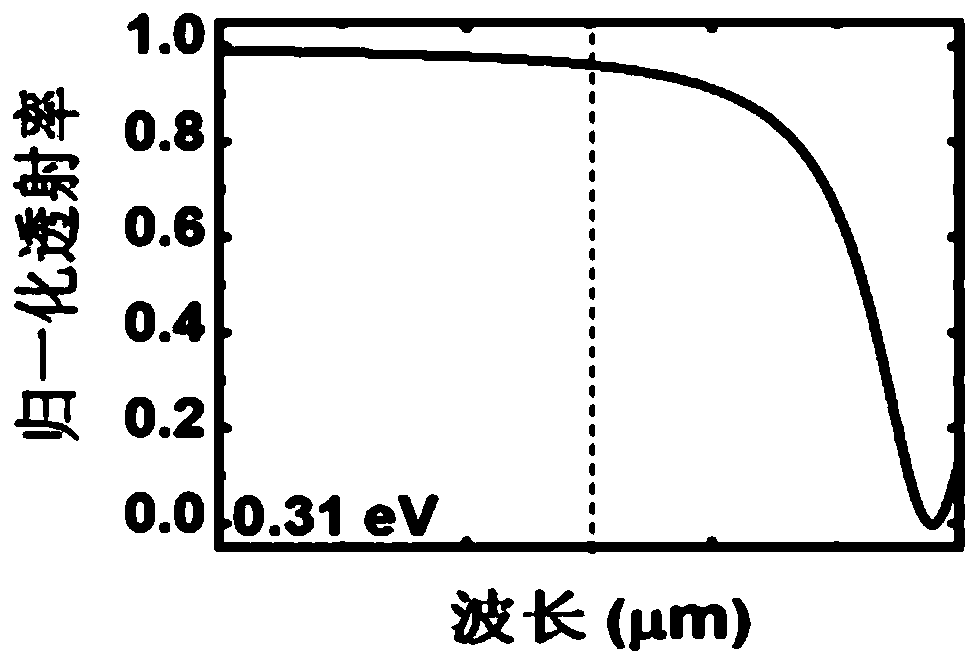

[0048] Such as figure 2 A graphene-silicon-based waveguide is shown, and its structural parameters are as follows: a silicon-on-insulator (SOI) wafer has a 340 nm thick top silicon layer and a 2 μm thick buried oxide layer, the waveguide is a ridge waveguide, and the waveguide width is 1 μm. The etching depth is 240nm, and the buried oxide layer at the lower part of the waveguide is etched away by hydrofluoric acid solution to reduce the absorption of mid-infrared light. According to theoretical calculations, the above-mentioned waveguide structure can support the propagation of the fundamental mode of mid-infrared light with a wavelength of 2.75 μm. In a specific embodiment, a microring resonator with a radius of 25 μm is used, the thickness of the aluminum oxide insulating cladding is 50 nm, and the coupling coefficient of the microring resonator is 0.98. Adjusting the Fermi levels of graphene to 0.31, 0.34, 0.37, 0.40, 0.43, 0.46, and 0.49eV respectively, the effective re...

Embodiment 2

[0052] Such as figure 2 A graphene-silicon-based waveguide is shown, and its structural parameters are as follows: a silicon-on-insulator (SOI) wafer has a 340 nm thick top silicon layer and a 2 μm thick buried oxide layer, the waveguide is a ridge waveguide, and the waveguide width is 1 μm. The etching depth is 240nm, and the buried oxide layer at the lower part of the waveguide is etched away by hydrofluoric acid solution to reduce the absorption of mid-infrared light. According to theoretical calculations, the above-mentioned waveguide structure can support the propagation of the fundamental mode of mid-infrared light with a wavelength of 2.75 μm. In a specific embodiment, a microring resonator with a radius of 25 μm is used, the thickness of the aluminum oxide insulating cladding is 50 nm, and the coupling coefficient of the microring resonator is 0.98. Adjusting the Fermi levels of graphene to 0.31, 0.34, 0.37, 0.40, 0.43, 0.46, and 0.49eV respectively, the effective re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com