Clamping-sealing structure and adjustment method of transmission-type receiving probe

A technology of receiving probes, clamping and sealing, applied in the direction of the casing of the measuring device, etc., can solve the problems of alignment adjustment, anti-corrosion, poor anti-rust performance, affecting the test effect, etc., to achieve precise angle alignment adjustment, convenient and flexible replacement, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

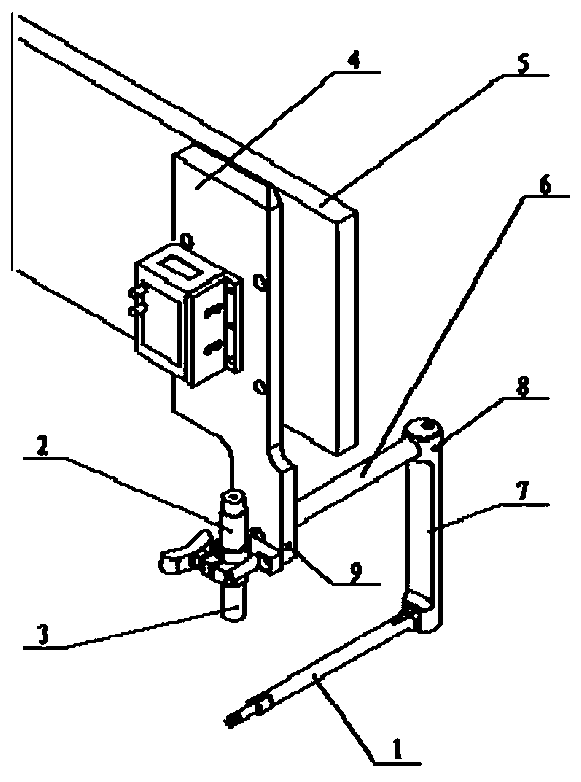

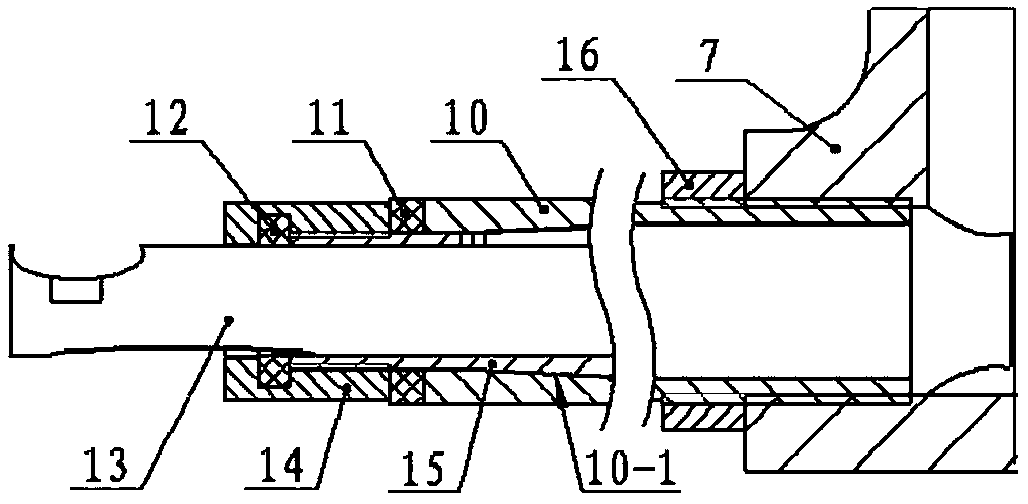

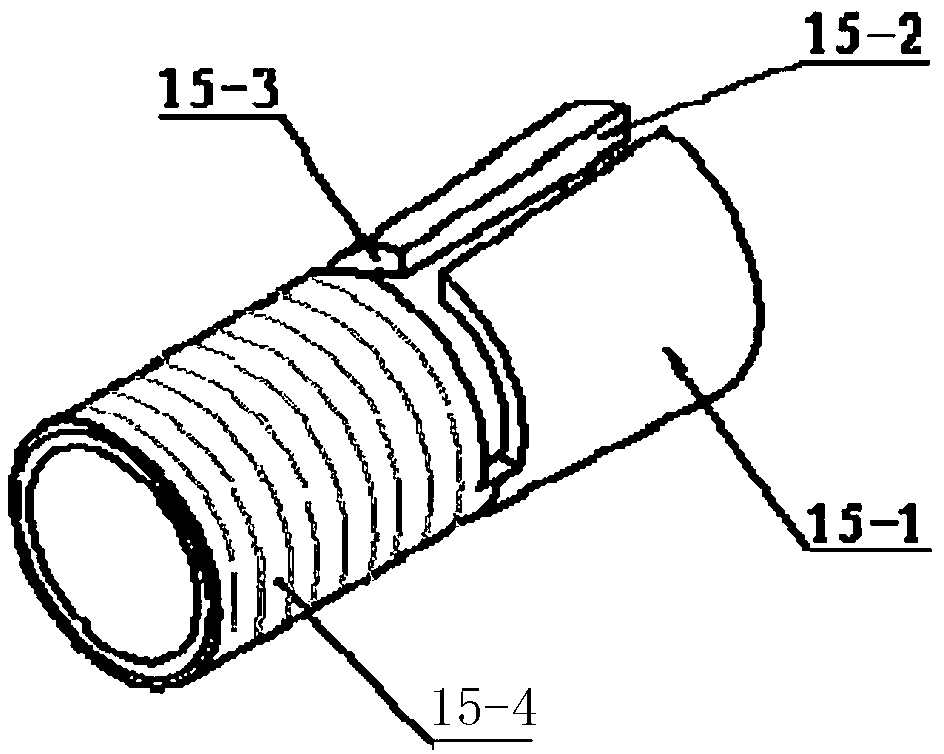

[0023] like figure 1 As shown, the clamping and sealing structure of the transmission-type receiving probe of the present invention includes a substrate 4 connected with a transmission-type transmitting probe device 2 and a structure main body 5 that fixes the substrate 4 . The bottom of the base plate 4 is provided with a shaft hole with a stop surface, and the stop shaft 6-2 with a stop surface on the left end of the upper flat rod 6 is plugged into the shaft hole with a stop surface, and the upper flat rod The stop shaft 6-2 of 6 is fixed in the shaft hole with the stop surface of the base plate 4 by a fastening screw 9. The right end head of last flat bar 6 is provided with vertical two wires up and down through notch 6-3 and a horizontal sliding notch 6-1. The right end of upper flat bar 6 is inserted in the horizontal axis hole of vertical shaft 7 upper end and is connected with vertical shaft 7 by fastening adjustment screw 8. The vertical shaft 7 is threadedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com