Charcoal-isolated drum sieve

A cylinder screen and cylinder technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of small screen contact area, reduce the gold loading capacity of activated carbon, and reduce the recovery rate of beneficiation, so as to achieve flexible screen replacement Convenience, avoid the loss of gold, and solve the effect of screen blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

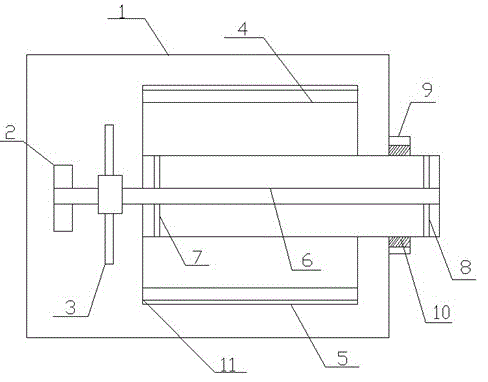

[0014] Such as figure 1 As shown, the second bearing seat 2, the sprocket 3, the cylinder screen 5 and the cylinder frame 11 are arranged in the adsorption groove 1, and the inner wall of the left end of the cylinder frame 11 is connected with a steel pipe 4, and there is a bearing 6 in the steel pipe 4, and the bearing 6. The axes of the steel pipe 4 and the cylindrical screen frame 11 coincide, the bearing 6 is connected to the first round steel 7 and the second round steel 8 welded on the inner wall of the steel pipe 4, and one end of the bearing 6 and the steel pipe 4 extends out of the adsorption groove 1, Two semicircular bearing bushes 10 are arranged at the contact between the steel pipe 4 and the adsorption tank 1 . One end of the bearing 6 is connected with the sprocket 3 and the second bearing seat 2 . One end of the steel pipe 4 outside the adsorption tank 1 is connected to the first bearing seat 9 through two semicircular bearing bushes 10 .

[0015] The spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com