Special aluminum oxide vibratory screening device

A technology of vibrating screening and screening device, applied in screening, chemical instruments and methods, solid separation, etc., can solve the problems of increasing operation and maintenance costs, equipment failure, affecting the production efficiency of aluminum electrolysis, and making it easy to replace the screen. and the effect of maintenance and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

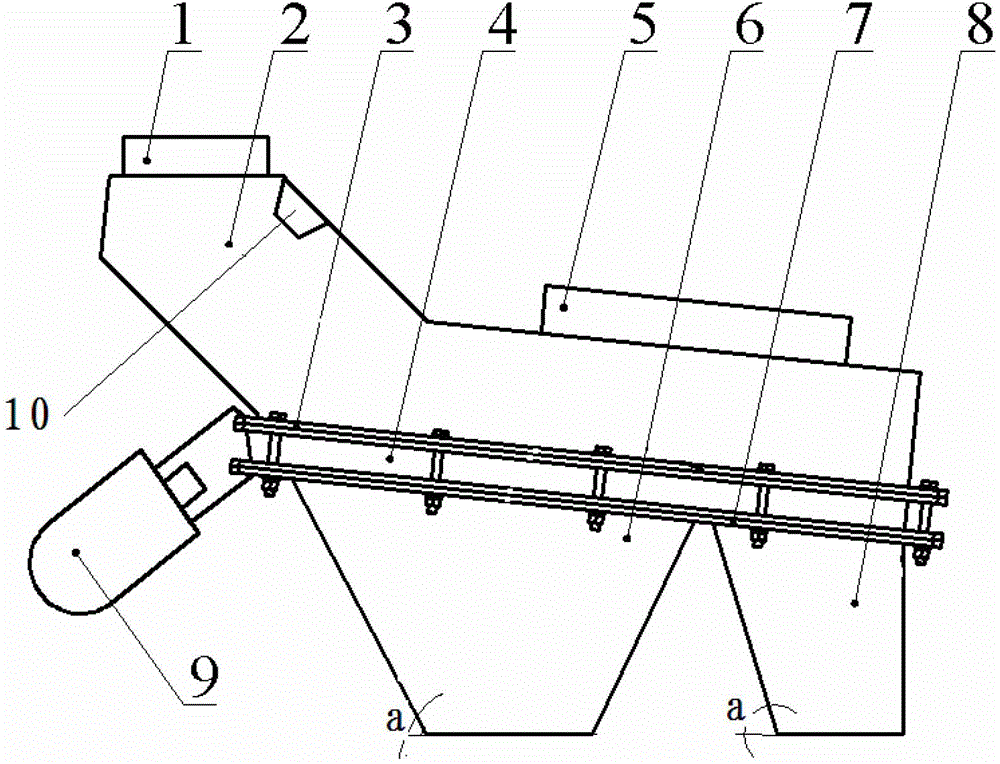

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, it includes a vibration source 9 and a housing 2, the upper end of the housing 2 is a feed port 1, the lower end of the housing is fixed with the flange 3 at the feed, and the flange 3 at the feed is connected to the screen The mesh group 4 is bolted; the lower end of the screen group is bolted to the discharge port flange 7, and the lower end of the discharge port flange is connected to the discharge port 6 and the debris port 8; the upper end of the discharge port 6 Cover the screen. After the bolts are removed, the screen group 4 can be pulled out from between the inlet flange 3 and the outlet flange 7;

[0019] For the convenience of maintenance and viewing, the top of the housing 2 is also provided with a maintenance port 5;

[0020] In order to ensure smooth discharge, the discharge angle a of the discharge port 6 and the sundries port 8 is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com