Rotary drum screening device and screening system

A screening device and trommel screen technology, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problem of incomplete washing of sand and gravel particles, low screening efficiency of sludge and waste soil, and inability to achieve reuse, etc. problems, to achieve the effect of easy replacement of the screen, easy inspection and maintenance, and easy blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

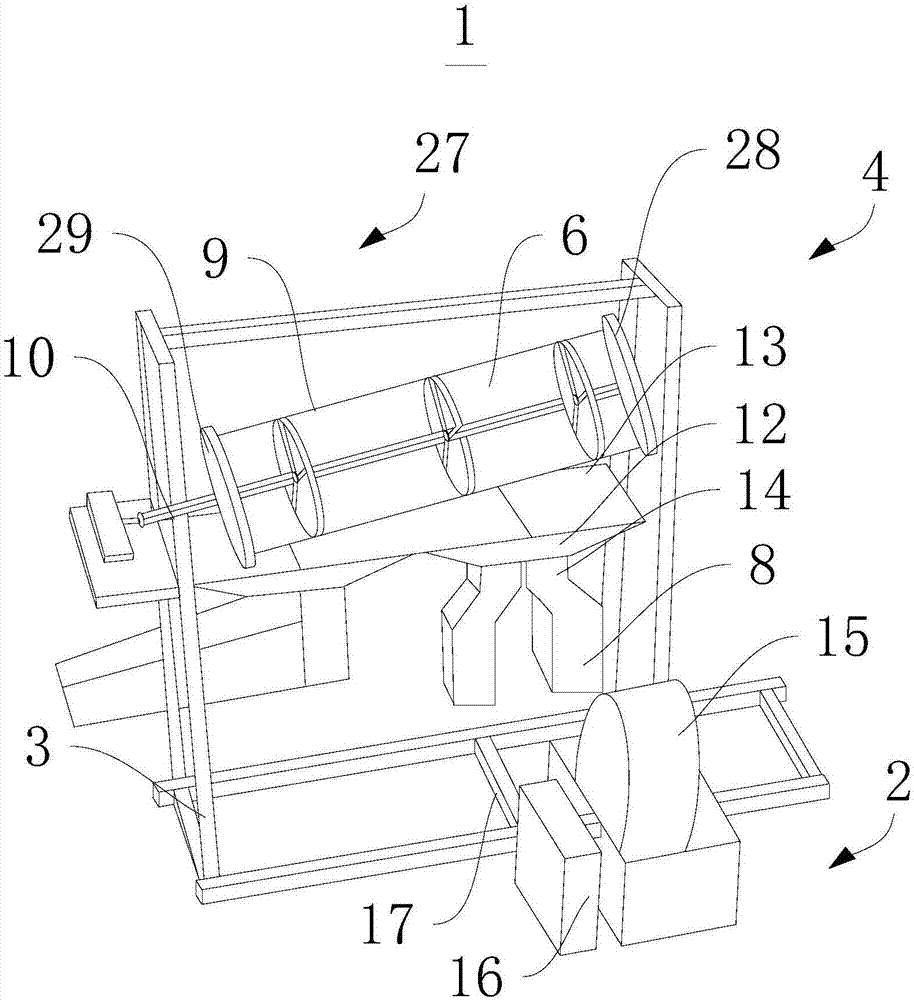

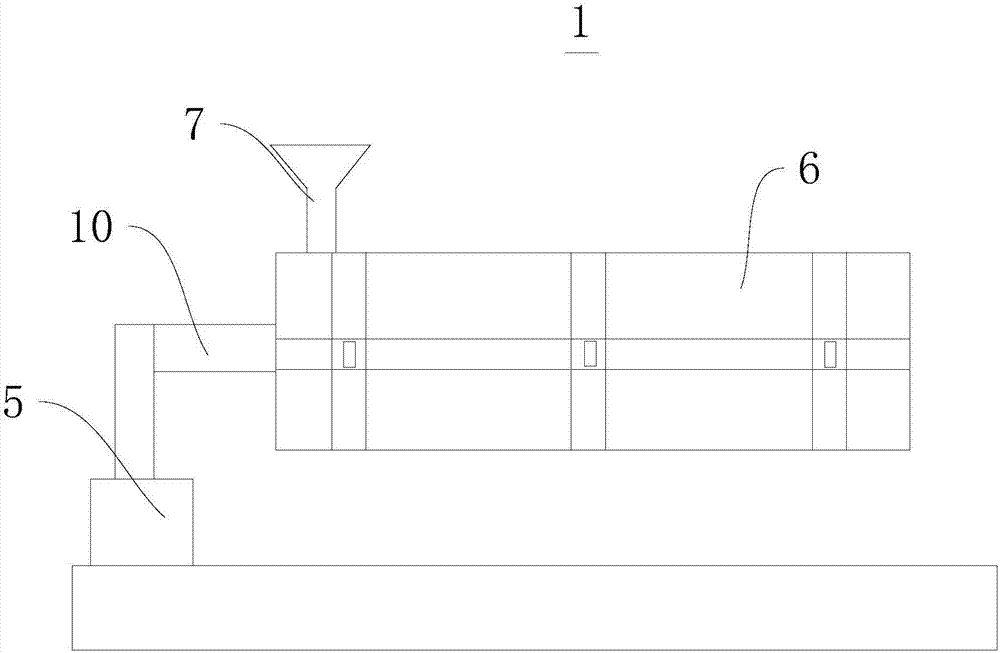

[0042] Please refer to figure 1 , with reference to Figure 2 to Figure 7 , this embodiment provides a drum screening device 1, which is mainly used to separate materials with different particles and different viscosities, so as to prevent materials from clogging due to different particle sizes, different humidity or different viscosities during the screening process. Sieve net 9.

[0043] In this embodiment, the drum screening device 1 includes a driving mechanism 2 , a frame 3 , a screening device 4 and a water supply device 5 . The screening device 4 is installed obliquely on the frame 3, the driving mechanism 2 is connected with the screening device 4, and the driving mechanism 2 is used to drive the screening device 4 to rotate around its axis.

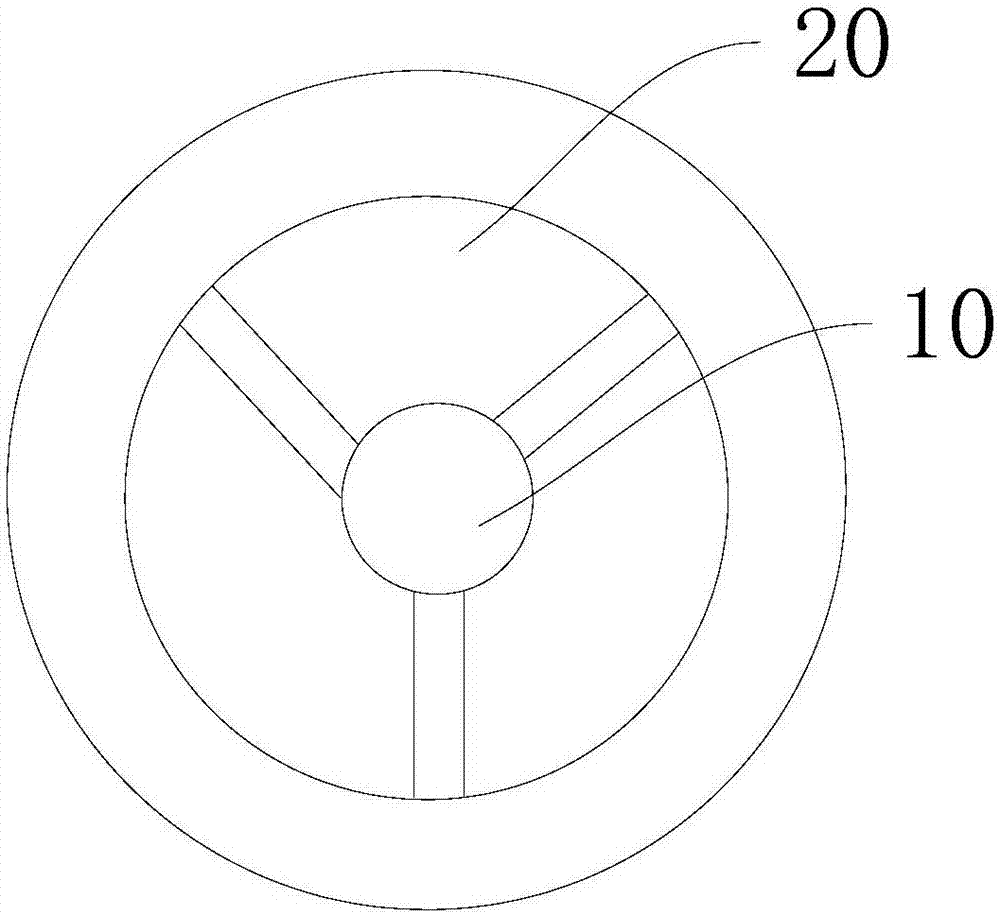

[0044] Wherein, the screening device 4 includes a drum 6, a feed port 7, a discharge port 8, and a receiving funnel 12; the drum 6 includes a sieve net 9 and a fixing mechanism 27, and the fixing mechanism 27 includes a first f...

no. 2 example

[0055] Please refer to Figure 8 , with reference to figure 1 , the present embodiment provides a screening system 25, the screening system 25 includes a recovery mechanism 26 and the drum screening device 1 above, the recovery mechanism 26 is connected with the screening device 4, and the recovery mechanism 26 is used for recycling the screening device 4 separated material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com