Minitype piezoelectric electret functional thin film preparation device

A piezoelectric electret and thin film preparation technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the mechanical problems of microporous structure membranes The performance and charge storage capacity cannot be effectively controlled, and the microstructure of the thin film is difficult to adjust accurately, etc., to achieve the effects of convenient and flexible replacement, high yield and stable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

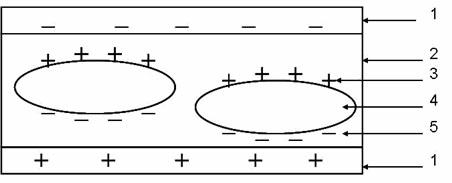

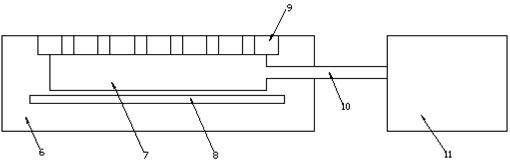

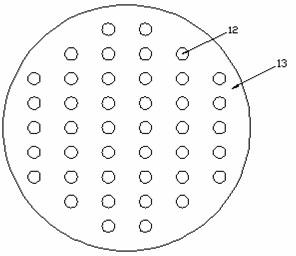

[0026] Using stainless steel as the base material and rotary vane vacuum pumps such as figure 2 The small piezoelectric electret film device shown. Such as figure 2 As shown, the upper part of the metal seat 6 is provided with a cavity 7, one side of the cavity 7 is connected to a vacuum pump 11 through a conduit 10, a heating plate 8 is provided at the lower part of the cavity 7, and a template 9 is provided on the top of the cavity 7, and the template is detachable. It is fixed on the metal seat 6 with rivets; the heating plate 8 and the pipe 10 are both fixed on the metal seat 6 and cannot be removed. Template 9 is structured as image 3 As shown, it is composed of a template punch 12 and a template base 13. The template base 13 has a circular structure, and the template punches 12 are evenly distributed on it; Figure 5 As shown, two sub-film preparation devices are placed up and down, the polymer films located on them are placed opposite each other, and the template punch...

Embodiment 2

[0029] Using stainless steel as the base material and rotary vane vacuum pumps such as figure 2 The small piezoelectric electret film device shown. The thickness of the first template and the second template is 2mm, the diameter of the template is 6cm, and the punching is Square holes, the distance between adjacent punching holes is 0.5mm. The first polymer film 14 is a polypropylene (PP) film with a thickness of 25 um, and the second polymer film 15 is a FEP film with a thickness of 12.5 um. Temperature 1, vacuum degree 1 and vacuum time 1 are respectively 90 o C, 6Pa and 5min; temperature 2, vacuum degree 2 and vacuum time 2 are 180 respectively o C, and 10min. The prepared thin film is electrically polarized by a contact method and a DC voltage of 3000kV, and the aluminum electrode is covered by a vacuum evaporation method. Quasi-static piezoelectric coefficient of the finally obtained PP / FEP composite piezoelectric electret film d 33 It is 300pC / N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com