Rockburst model testing device

A model test device, rockburst technology, which is applied in measurement devices, soil material testing, material inspection products, etc., can solve problems such as large size effect, small sample size, and differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

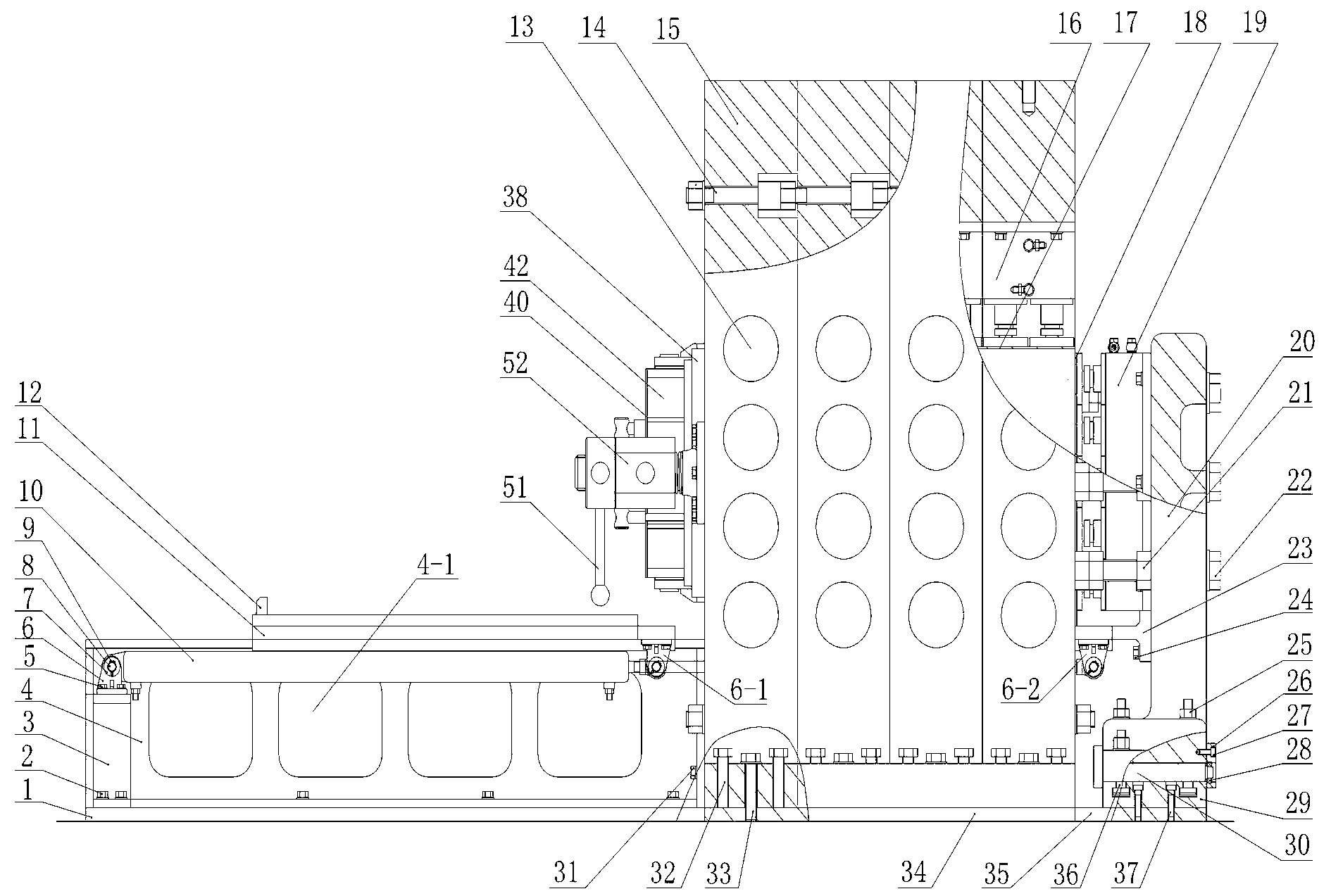

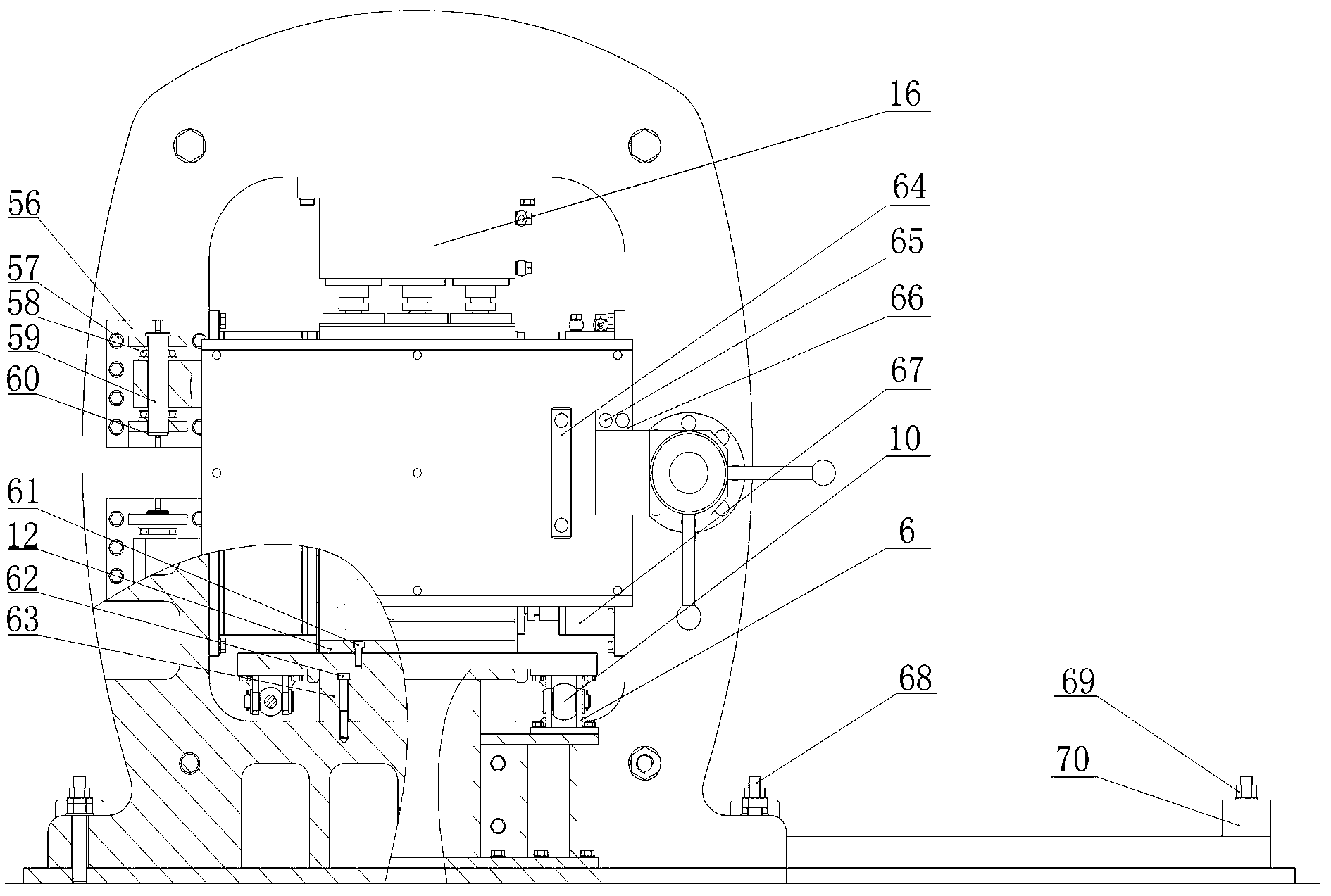

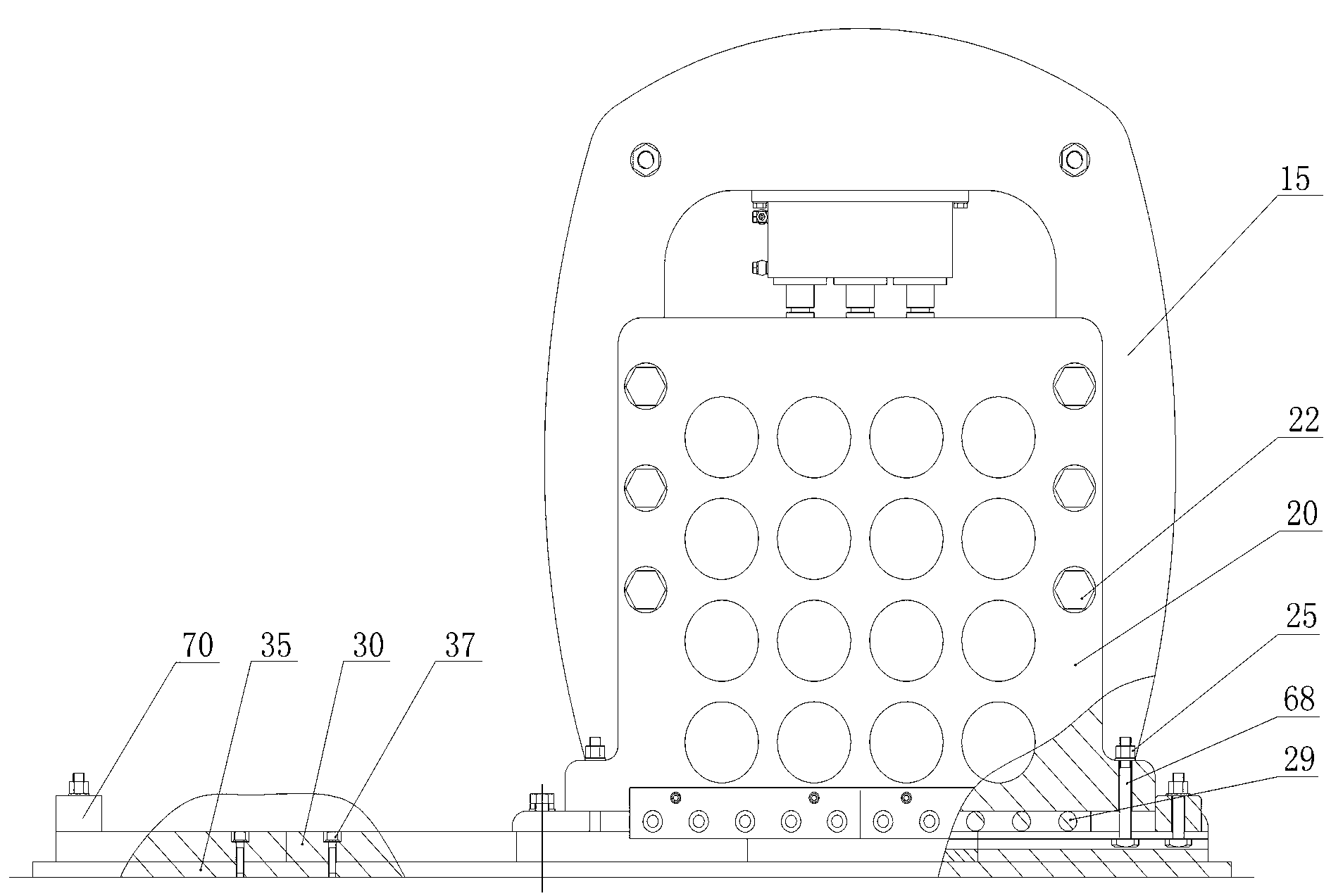

[0040] The rockburst model test device provided by the invention consists of a main engine and a hydraulic control system.

[0041] The host structure is as Figure 1 to Figure 4 As shown, it is mainly made up of a base, a model advance and retreat cylinder 10 and a load frame 15, wherein: the model advance and retreat cylinder 10 has two sets, which are symmetrically installed on both sides of the left part above the base. There are a plurality of bearing frames 15, which are horseshoe-shaped, aligned side by side and installed on the right part above the base; in a rectangular inner cavity formed by a plurality of horseshoe-shaped bearing frames 15, a lateral positioning beam 43 is installed on the left side, and a lateral positioning beam 43 is installed on the right side. The lateral uniformly distributed pressure loader 67 is installed, the top uniformly distributed pressure loader 16 is installed on the top, and the backing plate 63 for the model in place is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com