Hot-rolled section steel fly shear transmission crankshaft preparation method

A crankshaft and flying shear technology, which is applied in the field of preparation of flying shear drive crankshafts, can solve the problems that affect the cutting effect of flying shears, the quality of section steel sections, the inability to achieve precise control of flying shear transmission systems, and affect production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

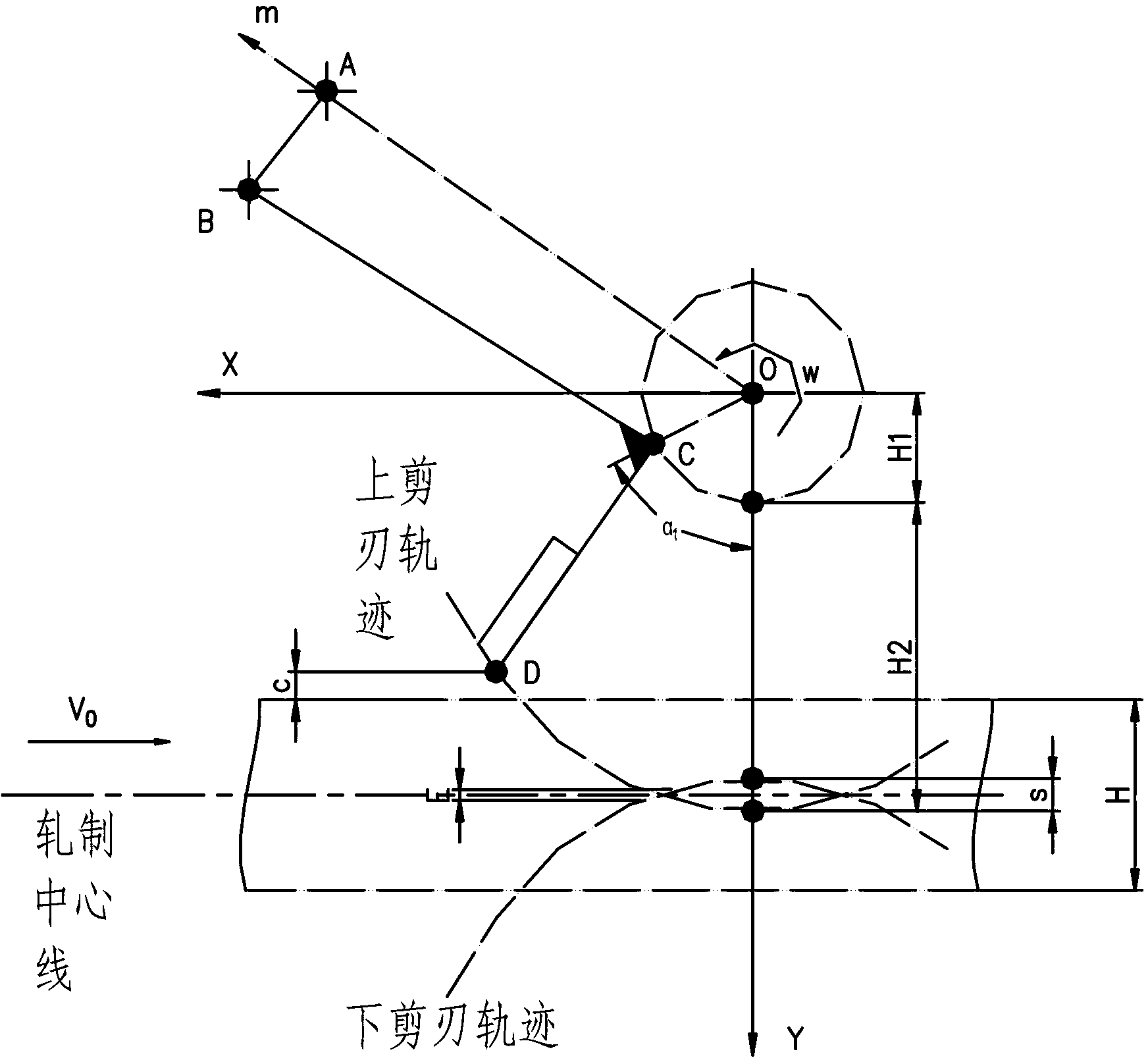

[0158] In order to facilitate a further understanding of the method of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

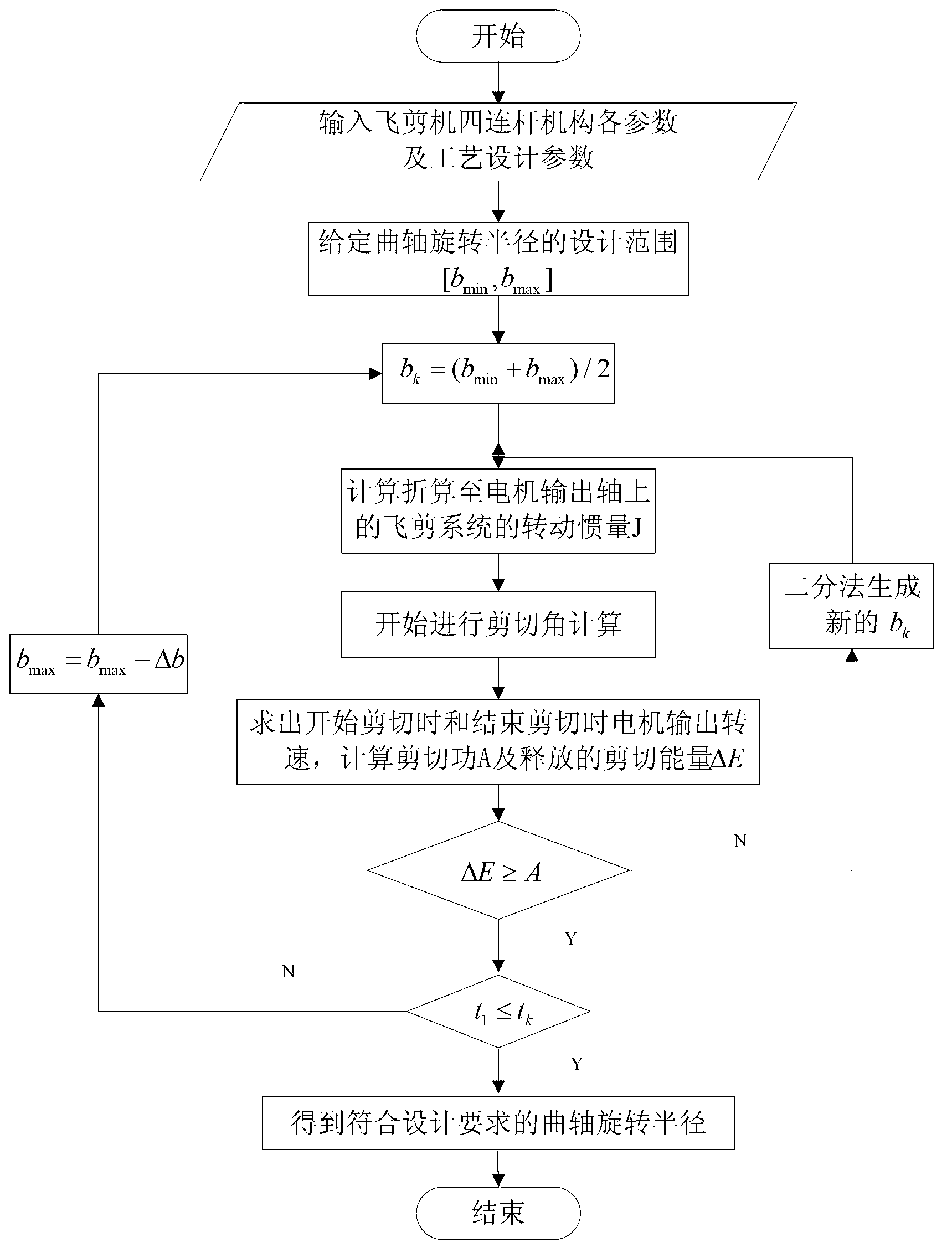

[0159] The preparation method of the hot-rolled section steel flying shear drive crankshaft provided by the present invention firstly determines the radius of rotation of the crankshaft, and then manufactures the drive crankshaft according to the length of each crankshaft, and its process is as follows figure 1 As shown, it specifically includes the following steps:

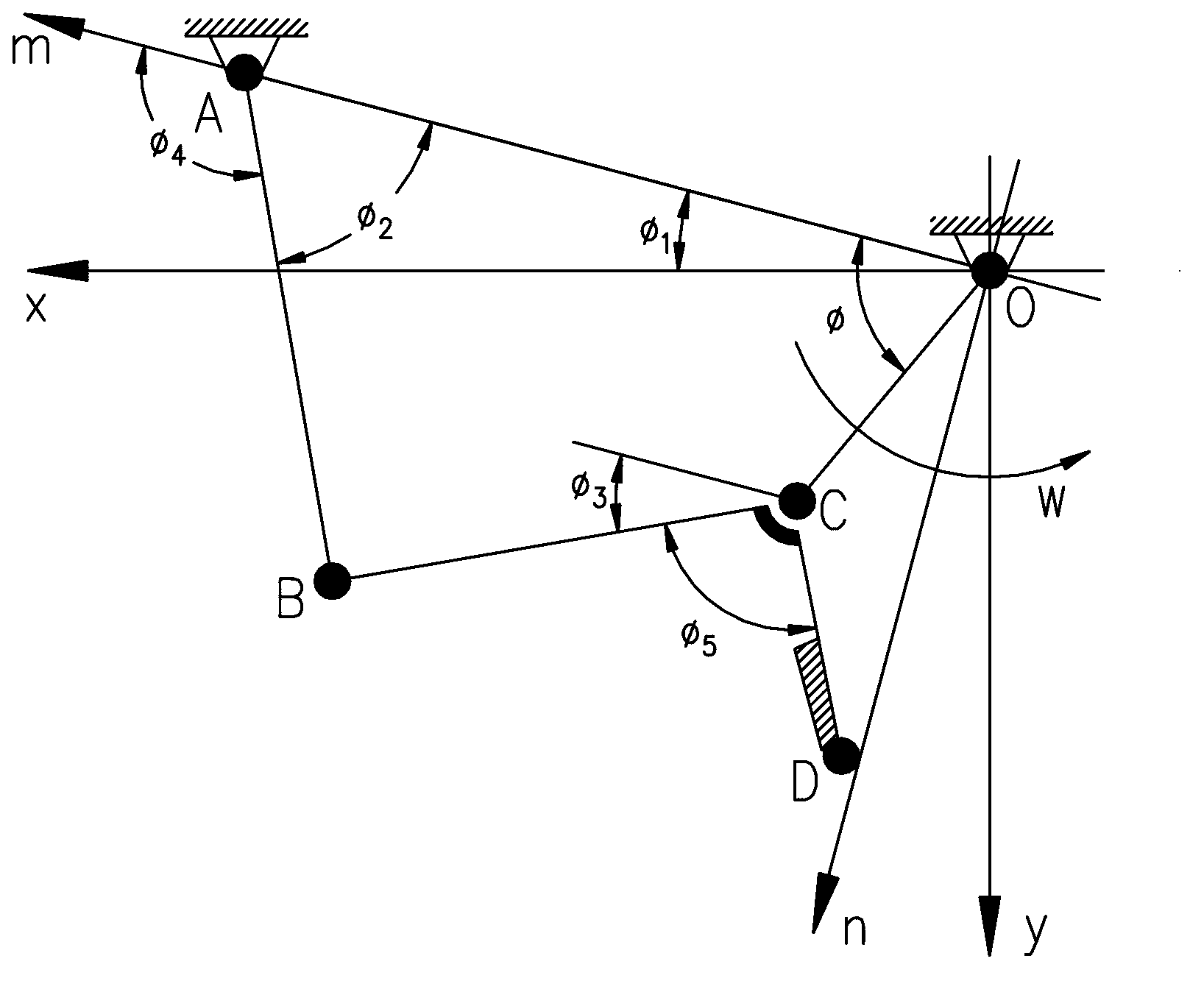

[0160] Step 1: Establish the corresponding coordinate system mon and coordinate system xoy. And according to the parameters to establish the relevant parameter equations in line with the mechanical principle. Given the relevant parameters of each component of the hot-rolled flying shear structure: the length of the fixed frame OA, the length of the connecting rod AB, the length of the connecting rod BC, the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com