Outdoor busbar electricity testing grounding device

A busbar and busbar connection technology, which is applied in the field of power transmission and transformation, can solve the problems of installing grounding wires and inability to conduct electrical inspections, and achieves no risk of discharge and heating, high practical value, and convenient electrical inspections and installation of grounding wires. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

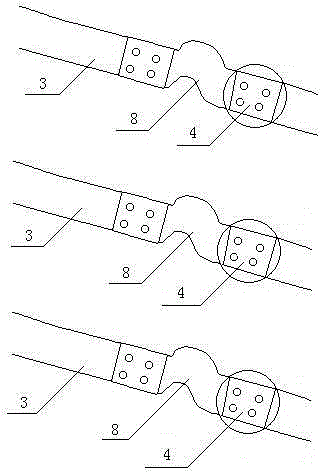

[0022] Install the "one"-shaped bare metal electrical inspection ground connection piece 5 made of a straight long strip of flat metal through the screw hole 7 on the "one"-shaped bare metal electrical inspection ground connection piece 5 through bolts and install it outdoors The fully insulated bow-shaped bus bar bridging part 3 is on the bus bar connecting plate 4 at both ends of the bow; it can realize the functions of facilitating the operation of electric inspection and installation of grounding wires. This embodiment can only be used on a bow-shaped busbar, and it is easy to discharge when it is close to the wall bushing, which is inconvenient to use.

Embodiment 2

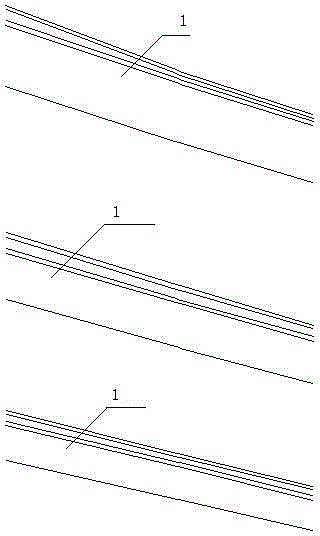

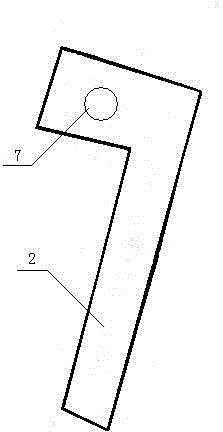

[0024] Make a piece of straight and long flat metal into an "L"-shaped "L"-shaped bare metal electrical test ground connector 2, and pass the bolt upside down through the screw hole on the "L"-shaped bare metal electrical test ground connector 2 7 Install on the bus connection plate 4 on one side of the bow-shaped bus bar of the fully insulated outdoor busbar 1; or weld the upright top to the bus connection plate 4 upright; this embodiment can be installed on the bus bar upright or upside down. It is very convenient to use and convenient for electrical inspection, but when it is installed upside down on an outdoor fully insulated busbar, it is easy to cause the grounding wire to slip when installing the grounding wire.

Embodiment 3

[0026] Make a piece of straight and long flat metal into a "]" type "]" type bare metal electrical inspection grounding connector 6, and install it through the screw hole 7 on the "]" type bare metal electrical inspection grounding connector 6 with bolts On the busbar connecting plate 4 on one side of the outdoor fully insulated burden busbar 3. Just can realize the effect that is convenient for electric test and installation ground wire operation. This embodiment can be very convenient to use on the bus bar, and the electric test is convenient, and the installation of the ground wire does not have the problem of slipping the ground wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com