Installing and removing the grounding wire

A technology of lifts and first sections, which is applied in the direction of overhead line/cable equipment, equipment for connecting/terminating cables, etc., can solve problems such as laborious and time-consuming, and achieve the effects of facilitating electrical inspection, improving reliability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

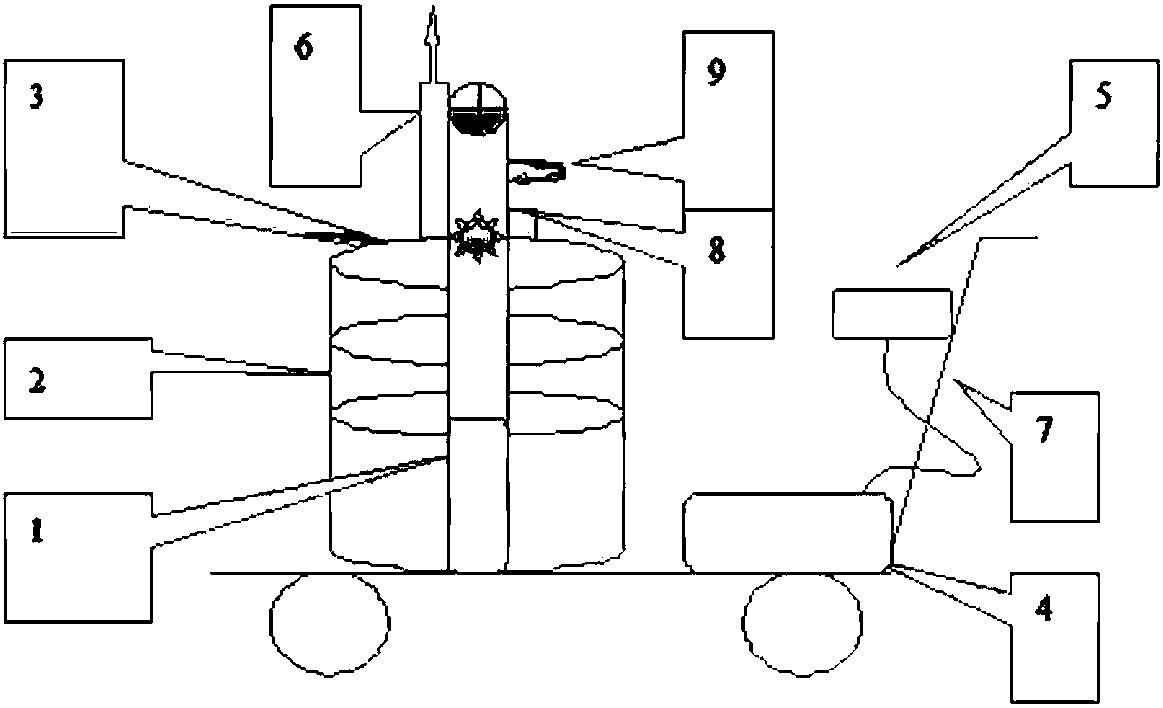

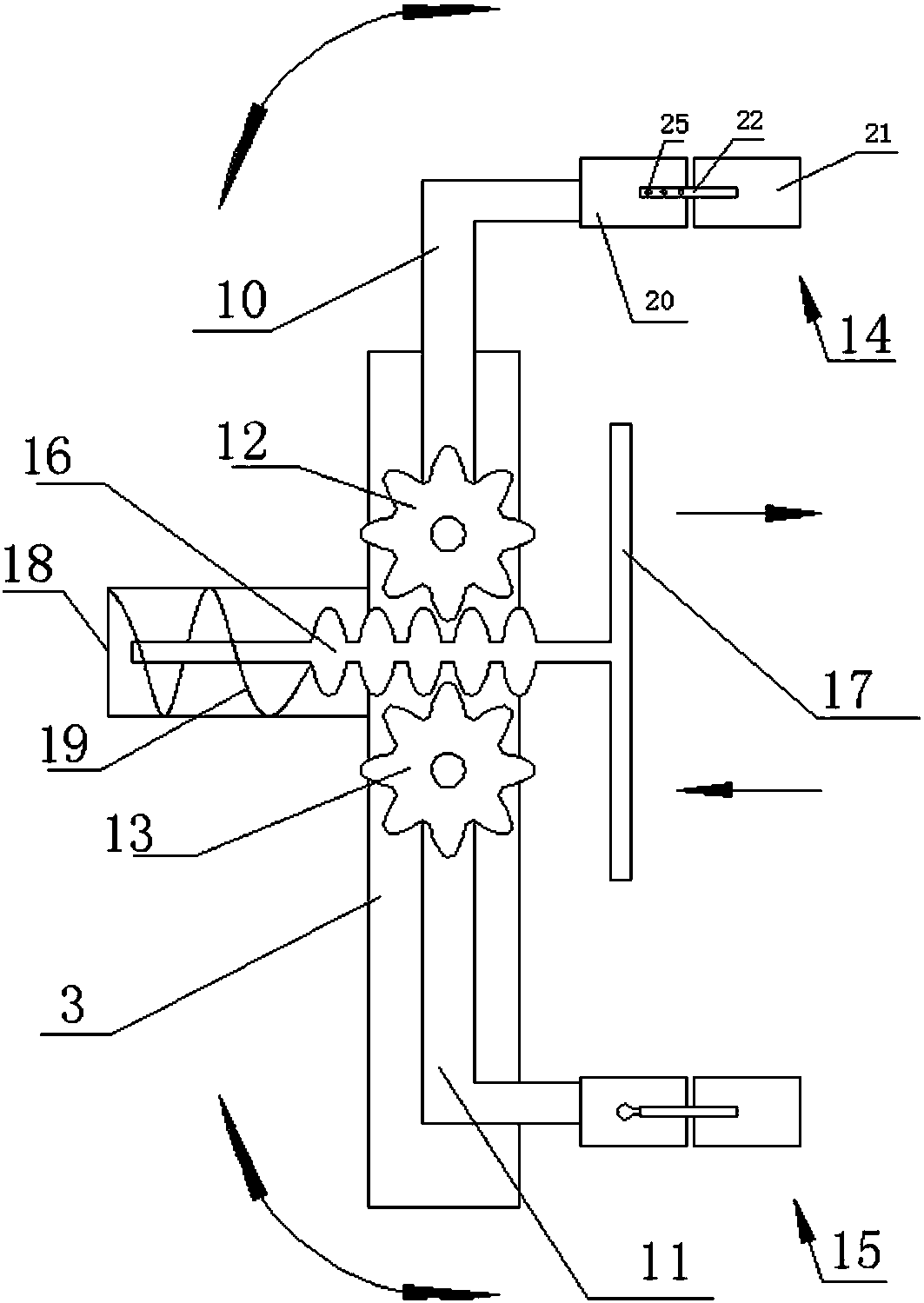

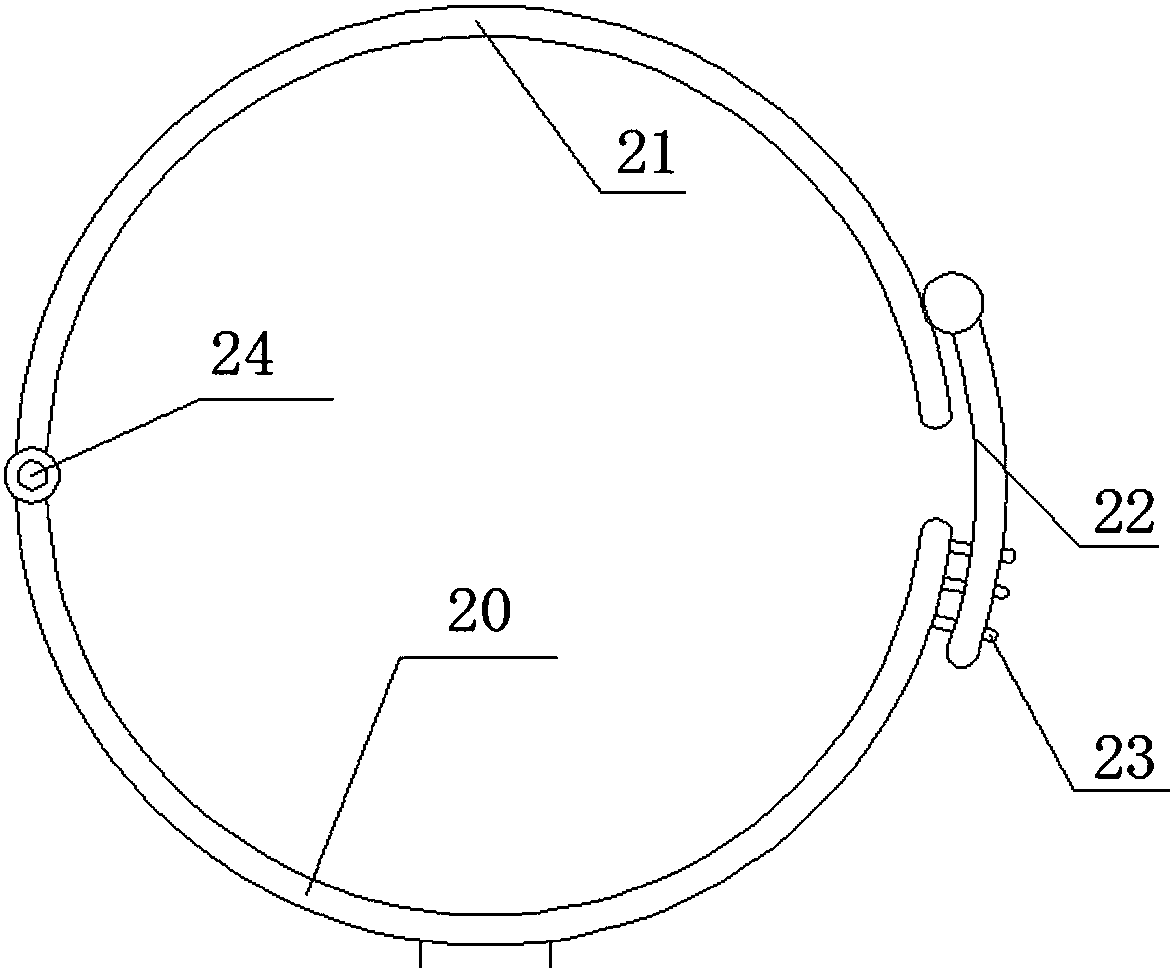

[0021] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

[0022] The invention provides an elevator for installing and dismantling grounding wires. The elevator includes an internal pressure storage steel pipe 1, a hydraulic rod 2, a first insulating rod 3, a motor 4 and a control handle 5; the first insulating rod 3 is connected to the hydraulic rod 2, and the hydraulic rod 2 The internal pressure storage steel pipe 1 is connected, the internal pressure storage steel pipe 1 is connected to a hydraulic pump, the hydraulic pump is connected to a motor, and an electroscope 6 is arranged on the first insulation rod 3 .

[0023] Internal pressure storage steel pipe 1, motor and hydraulic pump are arranged on cart 7.

[0024] On one side of the first section insulating rod 3, lighting 8 and insulating pull rod stabilizing guide 9 are installed.

[0025] The effect of stabilizing guide 9 is exactly that hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com