Compound spring type floating socket

A composite spring and socket technology, which is applied in the direction of coupling device, base/housing, electrical components, etc., can solve the problems of poor working reliability, no sealing protection, easy dust accumulation in pores, etc., and achieve high working reliability, high reliable connection, Good anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

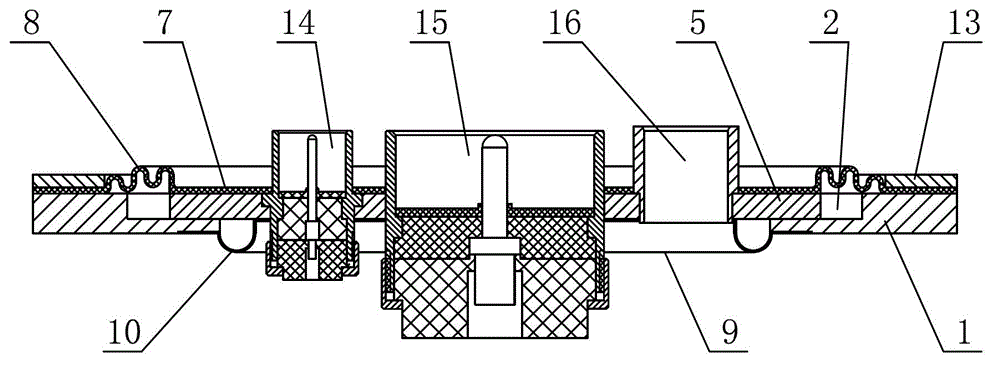

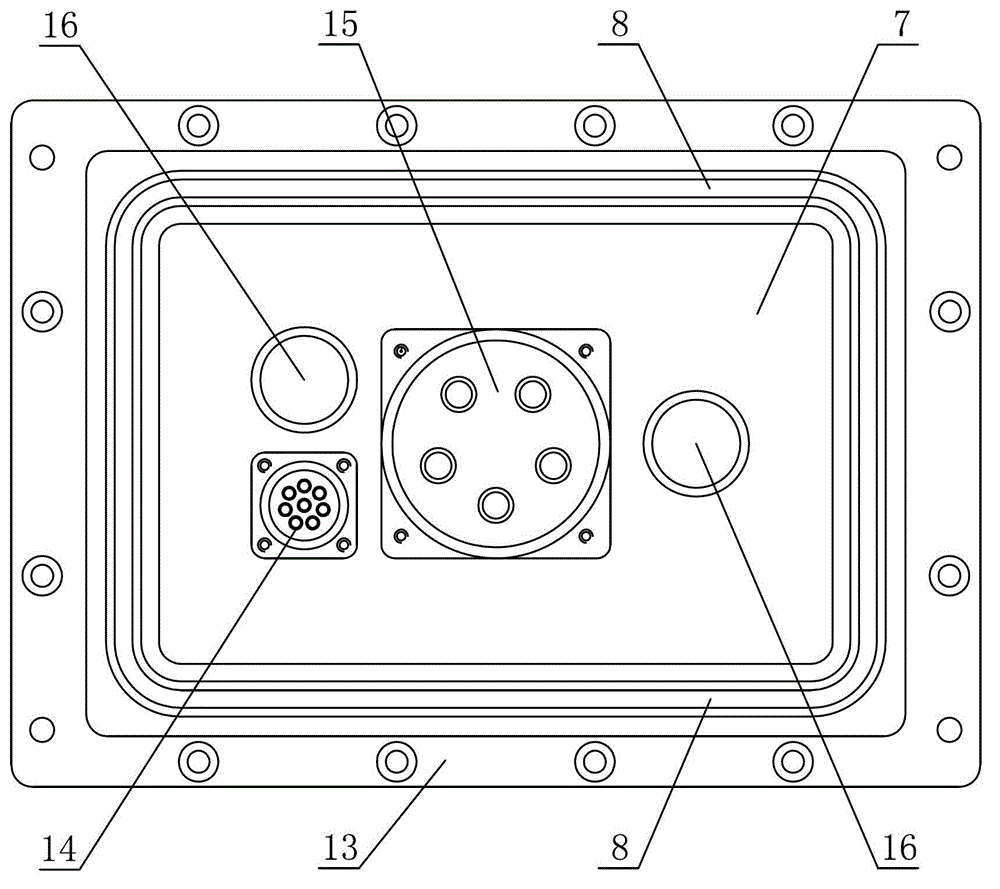

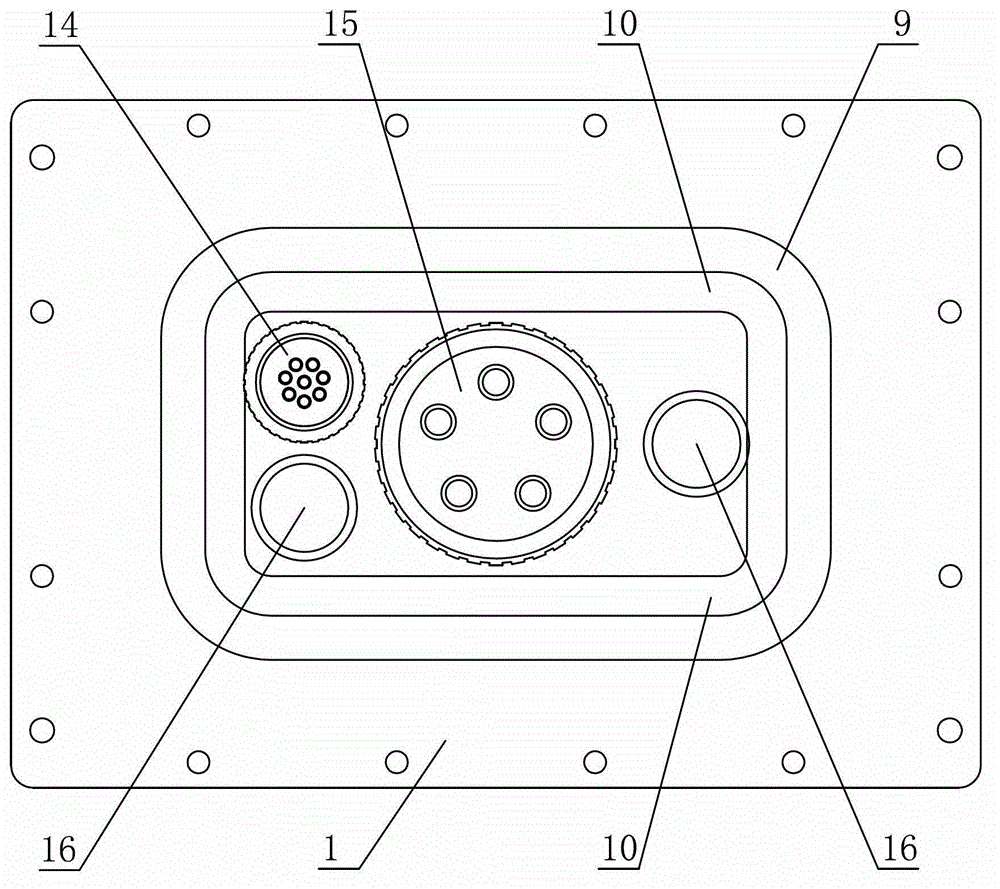

[0030] In such figure 1 , figure 2 , image 3 In the illustrated embodiment 1, a composite spring-type swimming socket includes a fixed seat 1 and a swimming seat 4 (see Figure 4 , The connector in the figure only shows the housing), the movable seat is provided with a connector and a connector guide 16, the connector includes a main connector 15 for transmitting large current and a secondary connector for transmitting control signals The plug-in 14, the plug-in guide is two asymmetrically arranged guide cylinders, the fixed seat is rectangular, the fixed seat is provided with a rectangular cavity 2 as a whole, and the bottom of the cavity is provided for passing through the connector and Insert the rectangular bottom hole 3 of the guide (see Figure 7 ), the movable seat 4 includes a rectangular movable plate 5 for fixing the above-mentioned connector and the insertion guide, the movable plate is arranged in a cavity on the fixed seat, and the thickness of the movable plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com