Universal floating type connector base

A connector and floating technology, applied in the field of universal floating connector seat, can solve the problems of poor contact, poor working reliability, poor anti-longitudinal vibration effect, etc., and achieve high working reliability, good anti-seismic effect, and high practicality. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

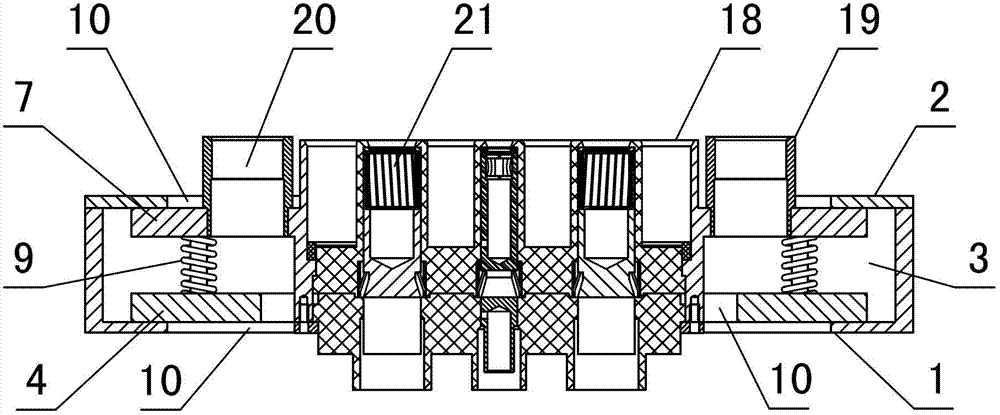

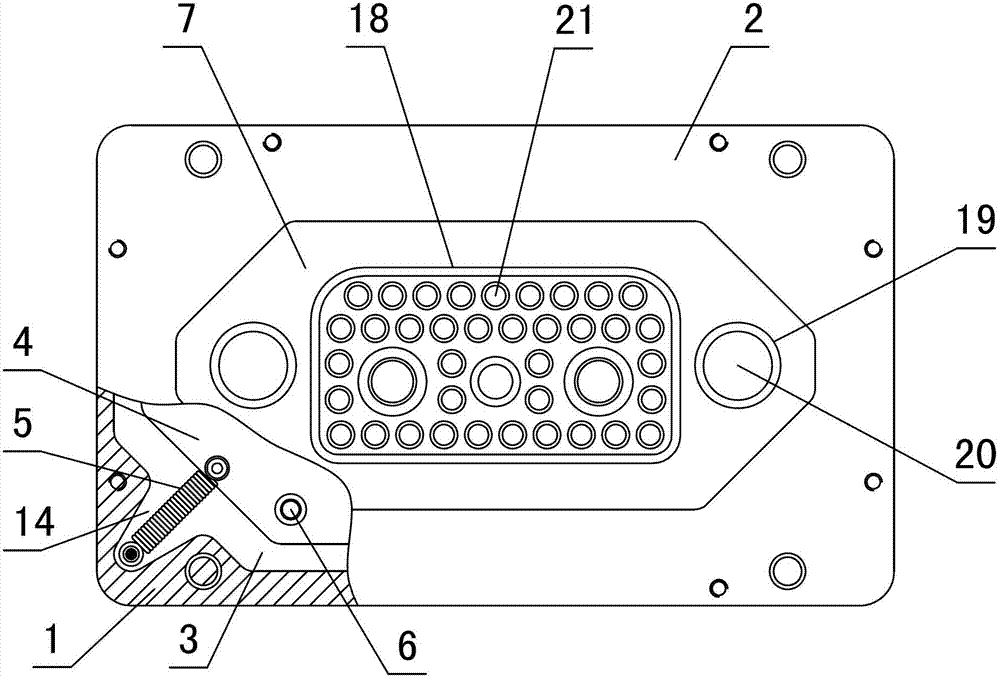

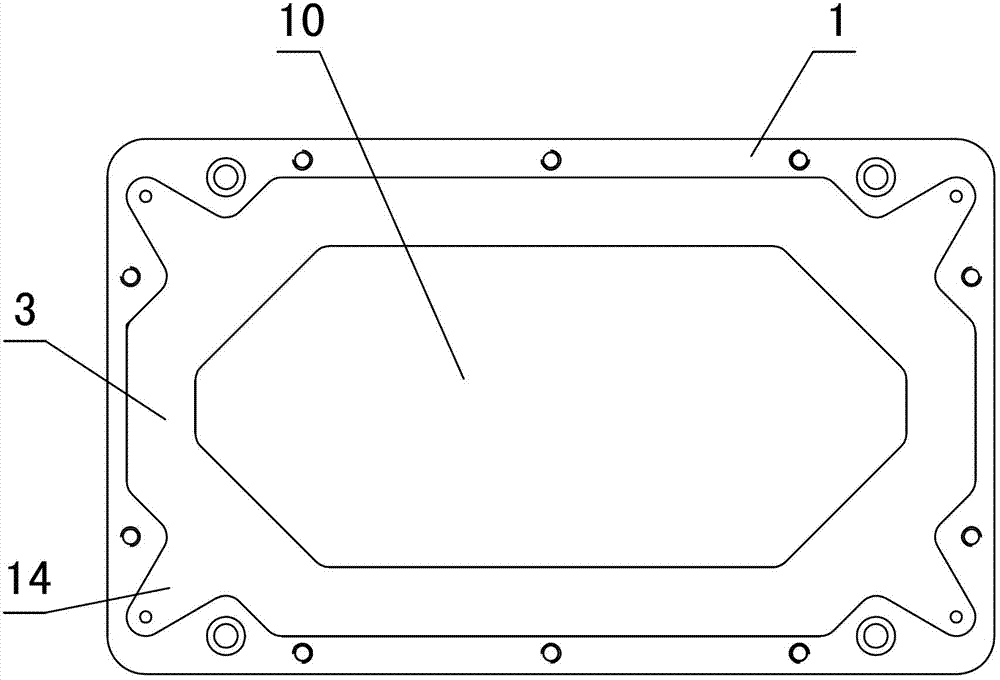

[0027] in such as figure 1 , figure 2 In the shown embodiment 1, a universal floating connector seat includes a floating seat and a socket arranged on the floating seat, and the floating seat includes a base 1 (see image 3 ) with cover plate 2 (see Figure 5 ), the base and the cover are rectangular. The base is provided with a cavity 3, and the bottom of the cavity is provided with a slide plate 4 that can slide laterally in the cavity (see Image 6 ), the edge of the skateboard and the base are connected by a number of tension springs 5, four guide columns 6 are fixed on the skateboard near the edge of the skateboard, and a socket mounting plate 7 is provided at the mouth of the cavity above the skateboard, and the skateboard and the socket are installed The shape and structure of the boards are the same, the middle part is a rectangle, and one group of opposite sides of the rectangle extends outwards and the length of the sides shrinks to form a trapezoidal structure 1...

Embodiment 2

[0030] The base of the universal floating connector base of embodiment 2 includes a base plate 15 and a coaming plate 16 fixed to the base plate (see Figure 4 ), the tension spring receiving groove is set on the coaming plate; the lower end of the guide column is fixedly connected with the slide plate, and the socket mounting plate is provided with a universal ball joint, and the universal ball joint includes a ball fixedly connected with the socket mounting plate Seat 11 and the spheroid 12 that is movably arranged in the ball seat, and described guide hole is arranged on the center of spheroid (see Figure 8 ), and the rest are the same as in Example 1.

Embodiment 3

[0032] Both the slide plate and the socket mounting plate of embodiment 3 are provided with a universal ball joint, and the universal ball joint includes a ball seat fixedly connected with the slide plate and the socket mounting plate and a ball movably arranged in the ball seat. The guide hole is set at the center of the sphere in the ball seat on the socket mounting plate, and the lower end of the guide rod is fixed with the sphere in the ball seat on the slide plate (see Figure 9 ), and the rest are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com