A car triangular window ultrasonic heat riveting all-in-one machine

A triangular window and hot riveting technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of poor water sealing performance, low precision, and easy deformation of the workpiece in the triangular window of a car, and achieve a bright appearance, The effect of high water sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

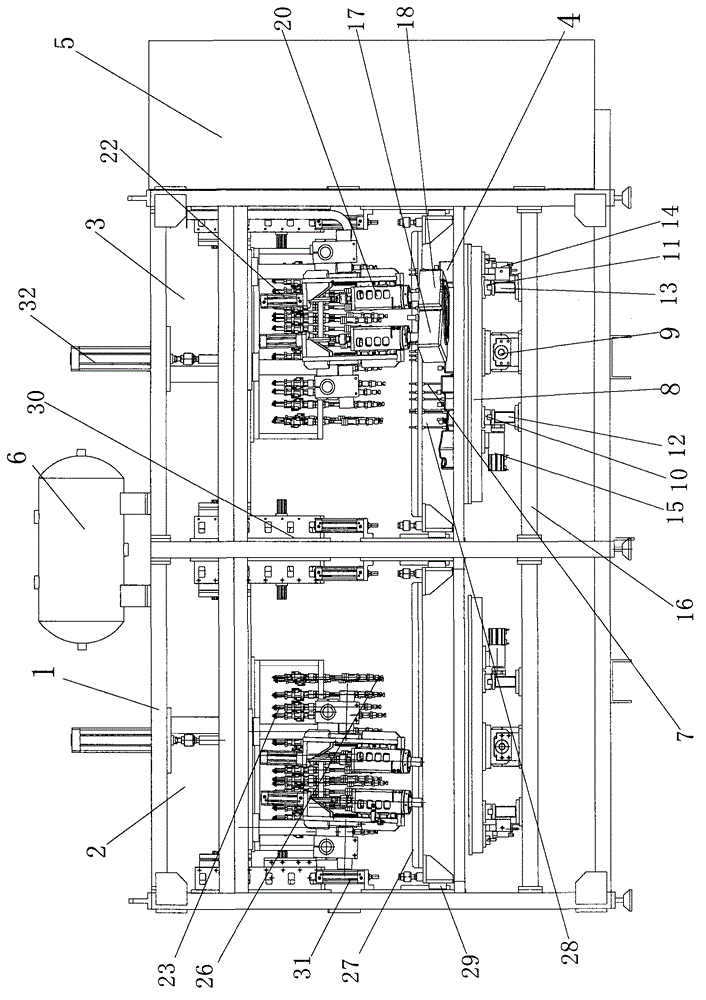

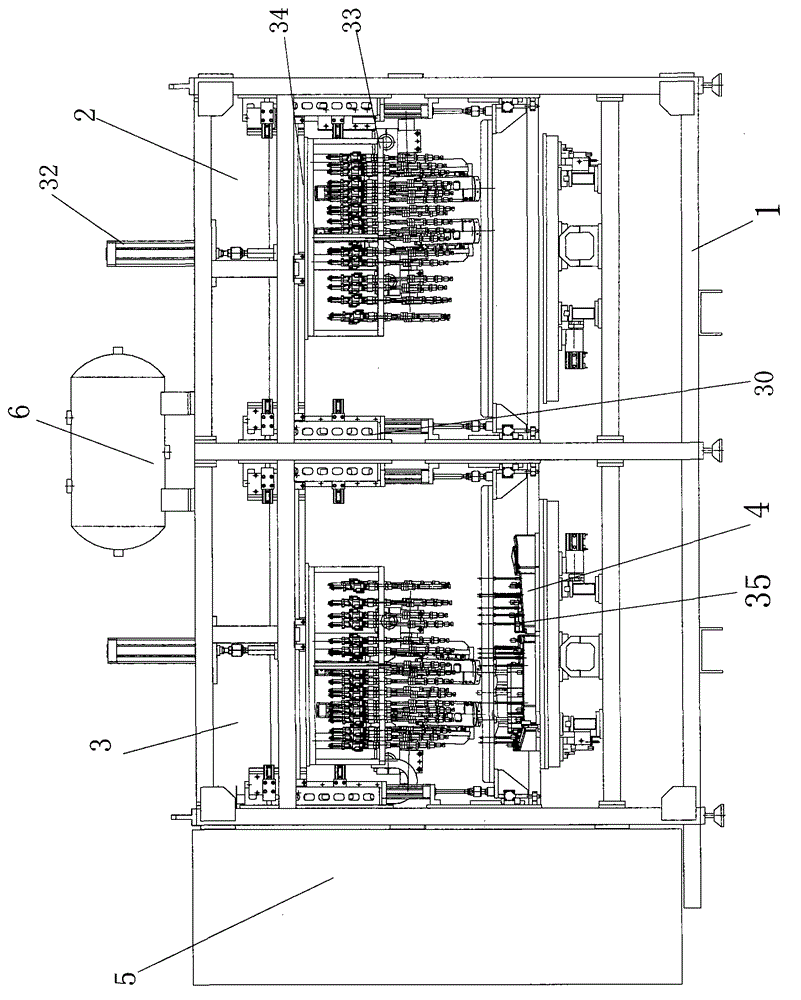

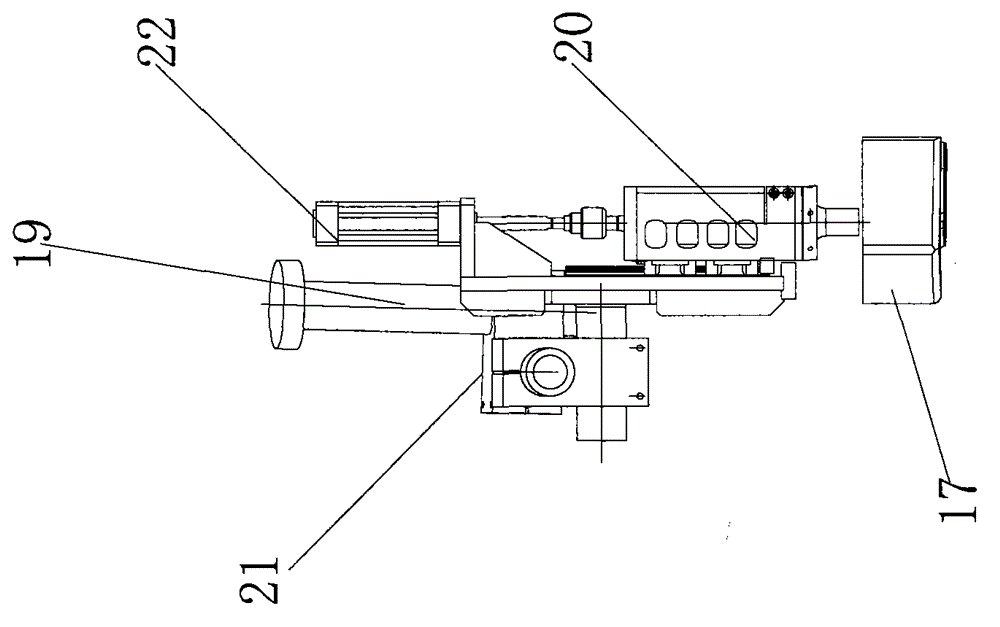

[0017] Example 1, such as figure 1 , figure 2 As shown, a car triangular window ultrasonic heat riveting integrated machine, including a frame 1, is characterized in that: the frame 1 is divided into a left car triangular window welding unit frame 2, a right car triangular window welding unit frame 3, The workpiece membrane platform 4 for welding the triangle window of the car, the workpiece membrane platform adjustment mechanism connected to the workpiece membrane platform 4, the workpiece pressure tool, and the ultrasonic welder with multiple welding heads arranged in the frame of each car triangle window welding unit One-station, multi-station hot riveting welding mechanism, ultrasonic welding station controlling multi-station welding head and lifting guide synchronous mechanism for lifting and lowering of multi-station hot riveting welding mechanism, and the side of frame 1 is also connected with gas circuit and circuit control The PLC control platform 5 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com