Plastic regulating frame

An adjustable frame and plastic technology, applied in textiles and papermaking, etc., can solve the problems of dirty sand cleaning, inconvenient operation, rough surface, etc., and achieve the effect of overcoming low manufacturing precision, convenient product installation, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

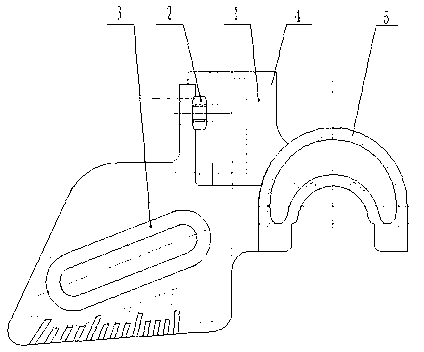

[0008] like figure 1 As shown, a plastic adjusting frame includes a plastic adjusting frame body 1, a nut 2 and an oblong hole gasket 3, the nut 2 is a hexagonal nut whose specification is GB6170M6×6, and the plastic adjusting frame body 1 is provided with a cylindrical boss 4 and There are two parts of the semicircular convex head 5, the metal oblong hole gasket 3 is arranged on the oblong hole on one side of the plastic adjusting frame body 1, the nut 2 is arranged in the hole on the cylindrical boss 4 side of the plastic adjusting frame body 1, and the plastic adjusting frame The body 1 and the nut 2 are arranged integrally. The material of the plastic adjusting frame body 1 is modified reinforced nylon.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap