Roadway work surface hydraulic roof connecting device

A working surface and hydraulic technology, applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., can solve the problems of wasting manpower and material resources, prone to safety accidents, and poor jacking effect, so as to reduce heavy physical labor, The effect of good stability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

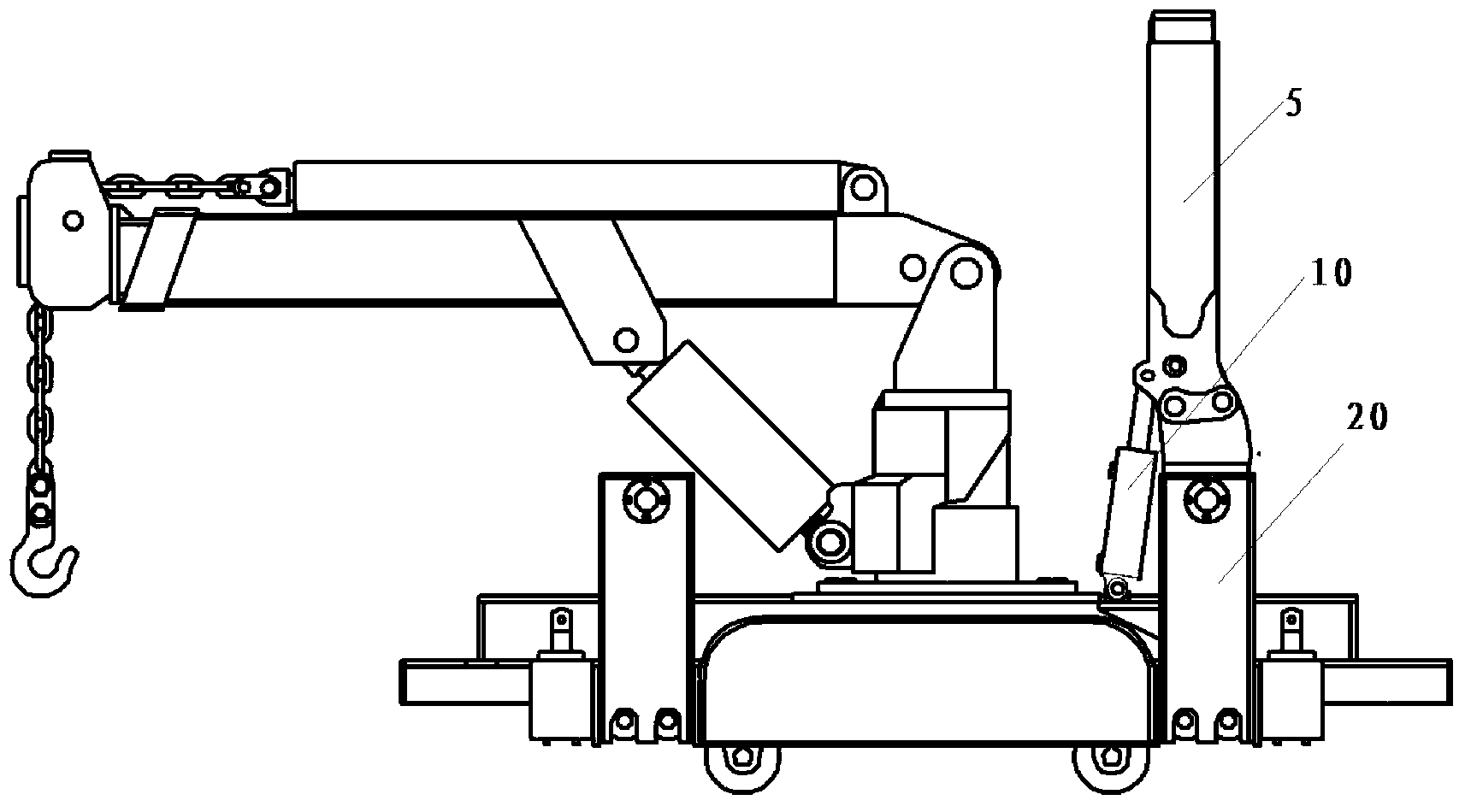

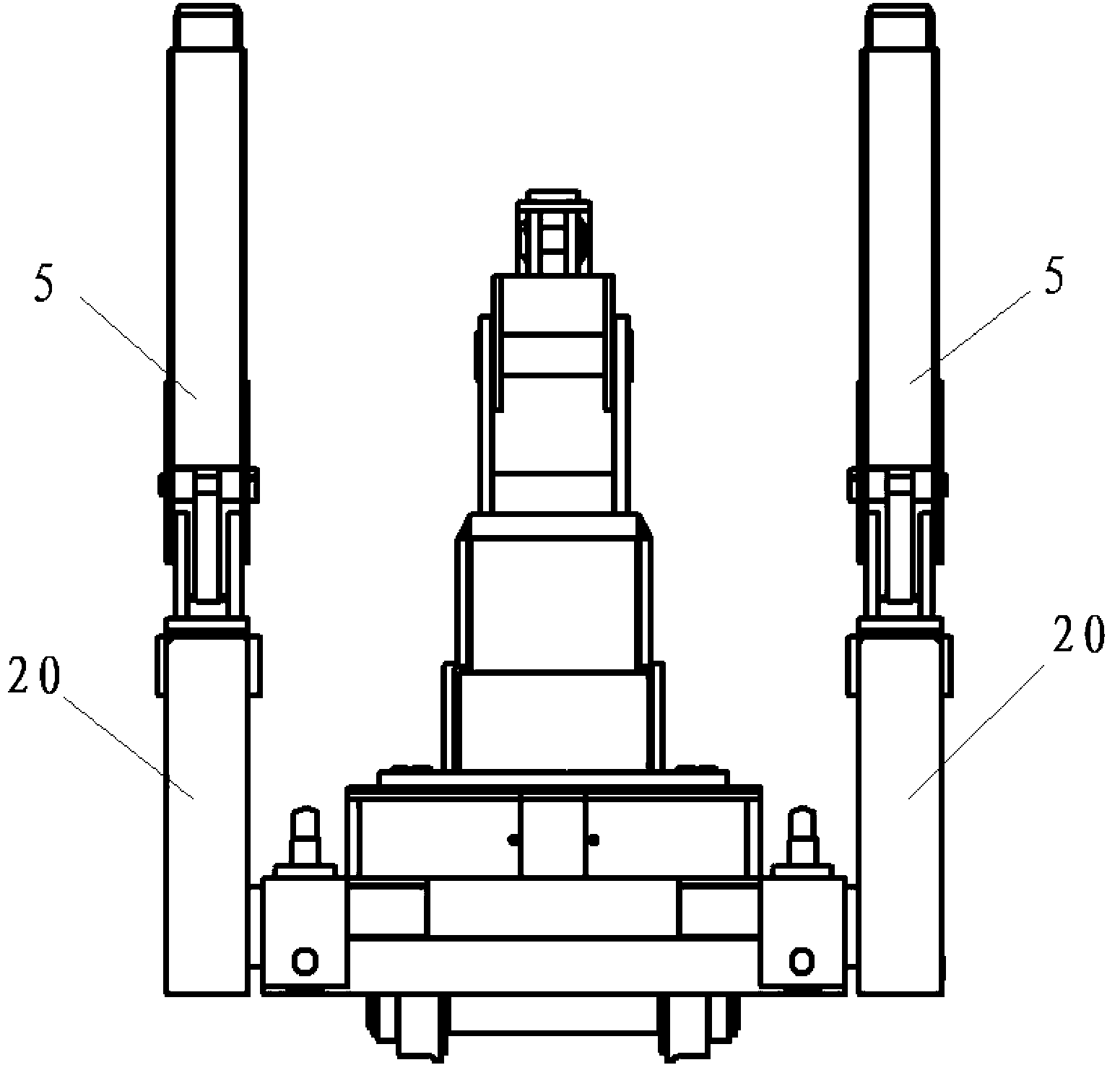

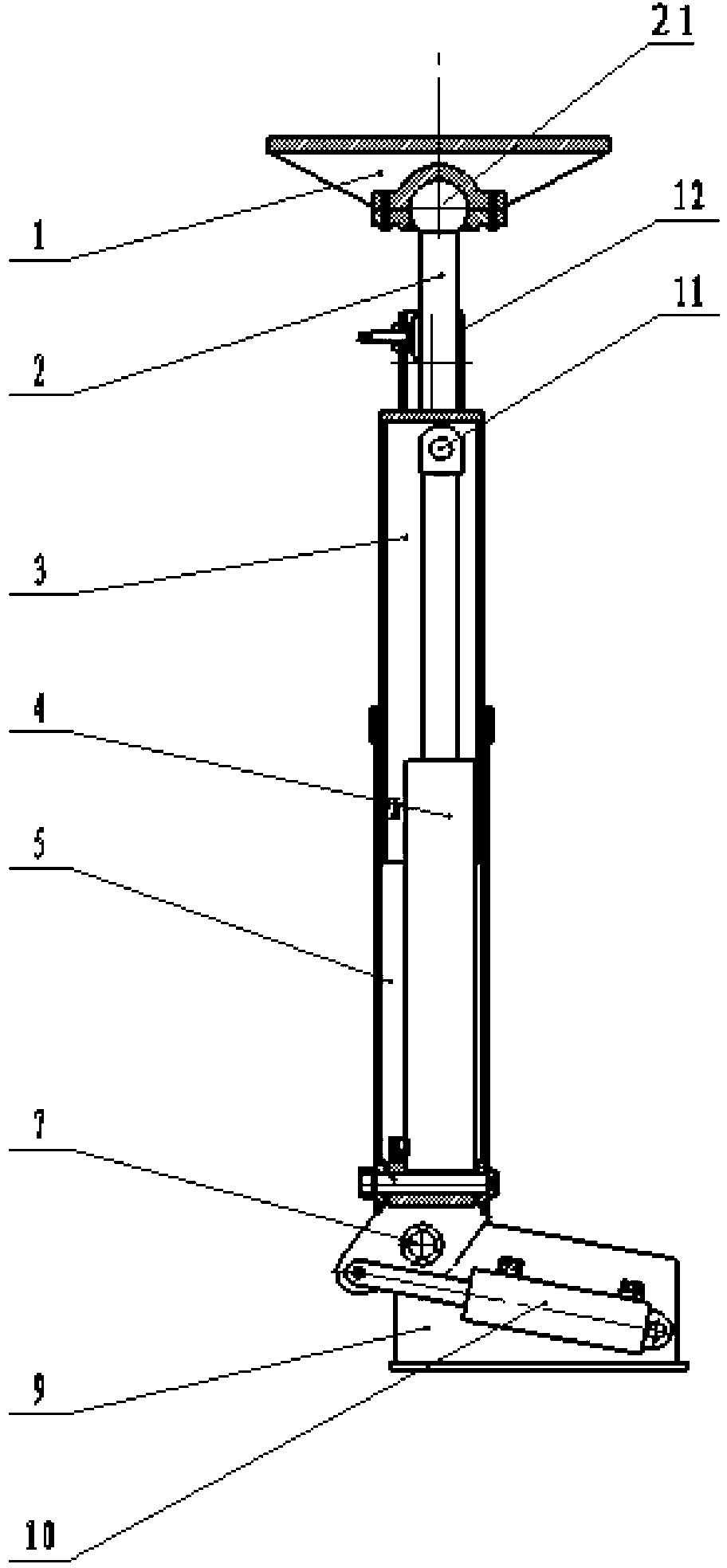

Embodiment Construction

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 3 As shown, the present invention comprises outer box 5, and outer box 5 is connected on the base 9 of top-connecting device by hinge, and the following of outer box 5 is fixed with support frame 20, and described support frame 20 contacts with the ground when working; Slideway is set in described outer box 5, and movable square box 3 is set on described slideway, and jacking jack 4 is arranged in outer box 5; 3 can slide along the slideway of the outer box 5, the top of the movable box 3 is provided with a sleeve 12, the sleeve 12 is provided with a connecting rod 2, and the connecting rod 2 is connected to the top plate 1.

[0017] In order to ensure uniform stress and adapt to the local unevenness and inclination of the top plate, the contact area between the top plate 1 and the ejector rod 2 is large, and the stability of the top connection is good. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com