Small melt-cast explosive melt mixing device

A mixing device and technology for melting and casting explosives, which are applied in the directions of explosives, mixers, and explosives processing equipment, etc., can solve problems such as large fluctuations in product quality, difficult process control, and lack of process equipment, so as to improve the safety operation level and process Controlled level, easy to clean up cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

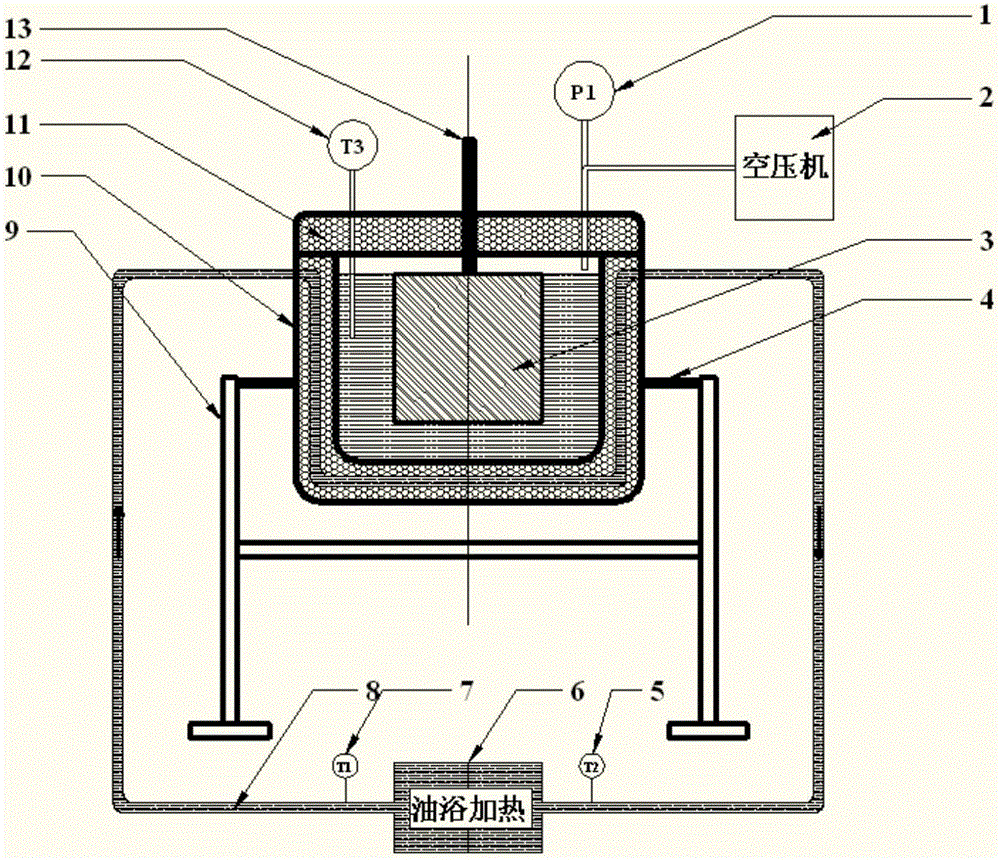

[0029] Such as figure 1 A schematic diagram of a small melt-mixing device for melt-cast explosives is shown. Use the device of the present invention to prepare 1 kg of fused-cast explosives, and the formula of fused-cast explosives consists of: 2,4,6-trinitrotoluene (TNT) 28\aluminum powder (Al)30\octogen (HMX)39\insensitive agent 3. Start the device of the present invention, turn on the 6-oil bath circulation heating system, use methyl silicone oil as heat transfer oil, heat 8-heat transfer oil, 7-the temperature range measured by the inlet thermometer is between 90°C and 91°C, and 5-the temperature measured by the outlet thermometer is The temperature range is 89°C~90°C, heat for 30min~40min, put the weighed TNT and desensitizing agent into the 10-pot, cover the 11-pot tightly, seal it with a polyurethane gasket, and open the 13- The stirring shaft drives the 3-stirring paddle to keep the speed at 20r / min~40r / min, monitor the 12-drug temperature thermometer, keep the tempe...

Embodiment 2

[0031] Such as figure 1A schematic diagram of a small melt-mixing device for melt-cast explosives is shown. Use the device of the present invention to prepare 1 kg of cast explosives, the formula of which is composed of: 2,4-dinitroanisole (DNAN) 28\aluminum powder 32\octojin 38\insensitive agent 2. Start the device of the present invention, turn on the 6-oil bath circulation heating system, use methyl silicone oil as the heat transfer oil, heat the 8-heat transfer oil, 7-the temperature range measured by the inlet thermometer is 106 ° C ~ 107 C, 5- the temperature measured by the outlet thermometer The temperature range is 104°C to 105°C, heat for 25min to 30min, put the weighed DNAN and insensitivity agent into the 10-pot, close the 11-pot lid tightly, seal it with a polycarbonate gasket, and open 13 - The stirring shaft drives the 3-stirring paddle to keep the speed at 20r / min~40r / min, monitor the 12-drug temperature thermometer, keep the temperature between 103°C~104°C, k...

Embodiment 3

[0033] In this embodiment, the device of the present invention is used to realize the preparation process of molten-cast explosives.

[0034] Such as figure 1 A schematic diagram of a small melt-mixing device for melt-cast explosives is shown. Use the device of the present invention to prepare 1kg of fused and cast explosives, the formula of fused and cast explosives consists of: 3,4-dinitrofurazanyl oxide furazan (DNTF) 28\ aluminum powder 31\ Octojin 39\ Insensitivity agent 2. Start the device of the present invention, turn on the 6-oil bath circulation heating system, use cumene as heat transfer oil, heat 8-heat transfer oil, 7-the temperature range measured by the inlet thermometer is between 120°C and 121°C, and 5-measure by the outlet thermometer The temperature range is 118°C to 119°C, heat for 20min to 25min, put the weighed DNAN and insensitivity agent into the 10-pot, cover the 11-pot tightly, and seal it with a polyethylene-propylene rubber sealing washer , turn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com