Device and method for lively replacing tensile rod insulators of 10kV line by using ground potential working method

A live replacement, insulator technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of insecurity and low work efficiency, and achieve the effect of reducing physical labor, improving work efficiency, and reducing the number of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

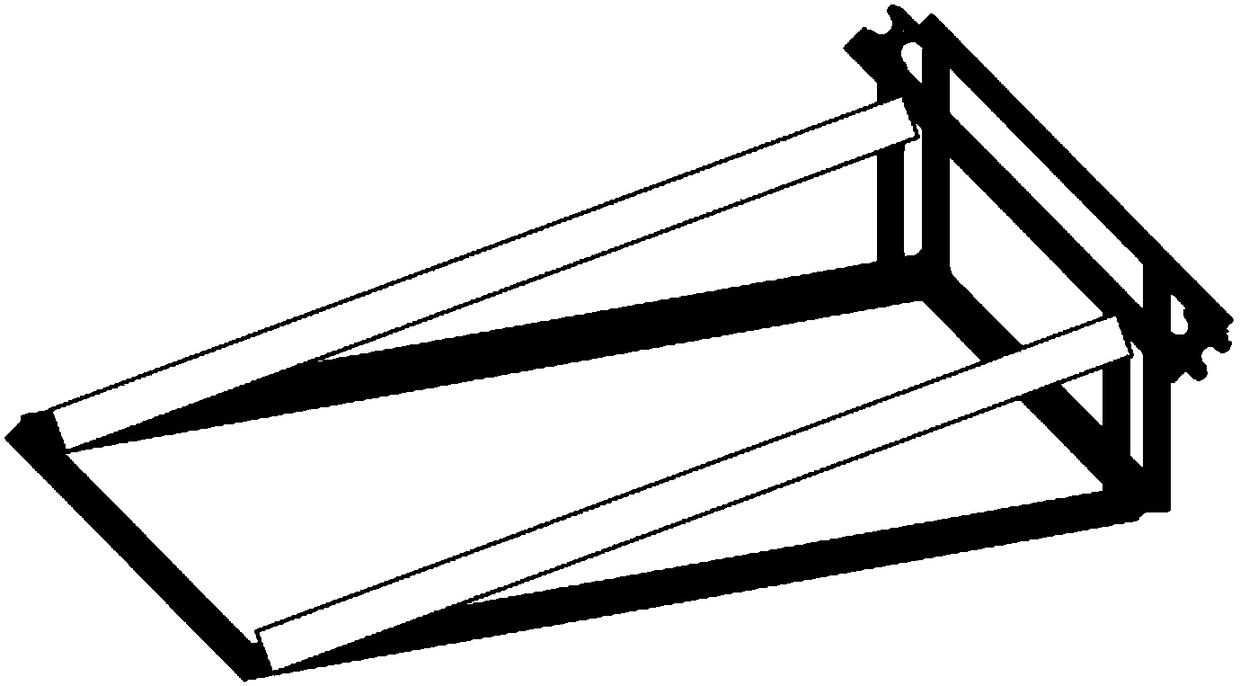

[0029] In the first embodiment, as in figure 1 As shown, a 10kV line ground potential live replacement device for strain rod insulators, including cross-arm brackets and wire tightening devices, in which:

[0030] The cross-arm support includes a rectangular bottom frame, a fixed frame vertically connected to one end of the rectangular bottom frame, the fixed frame is two "π"-shaped brackets, and the top of one "π"-shaped bracket is connected to the other end of the rectangular bottom frame through a connecting plate Connection, a pulley is provided on the upper connection of the two "π" type brackets;

[0031] The wire tightening device includes a wire clamp, a Dyneema rope and a wire tightener; wherein the Dyneema rope is set on the pulley of the cross-arm bracket, and one end of the Dyneema rope is clamped on the wire clamp along the length direction of the wire clamp. On the thread clamp, the other end of the Dyneema rope is wound on the thread tensioner.

[0032] Prefer...

Embodiment 2

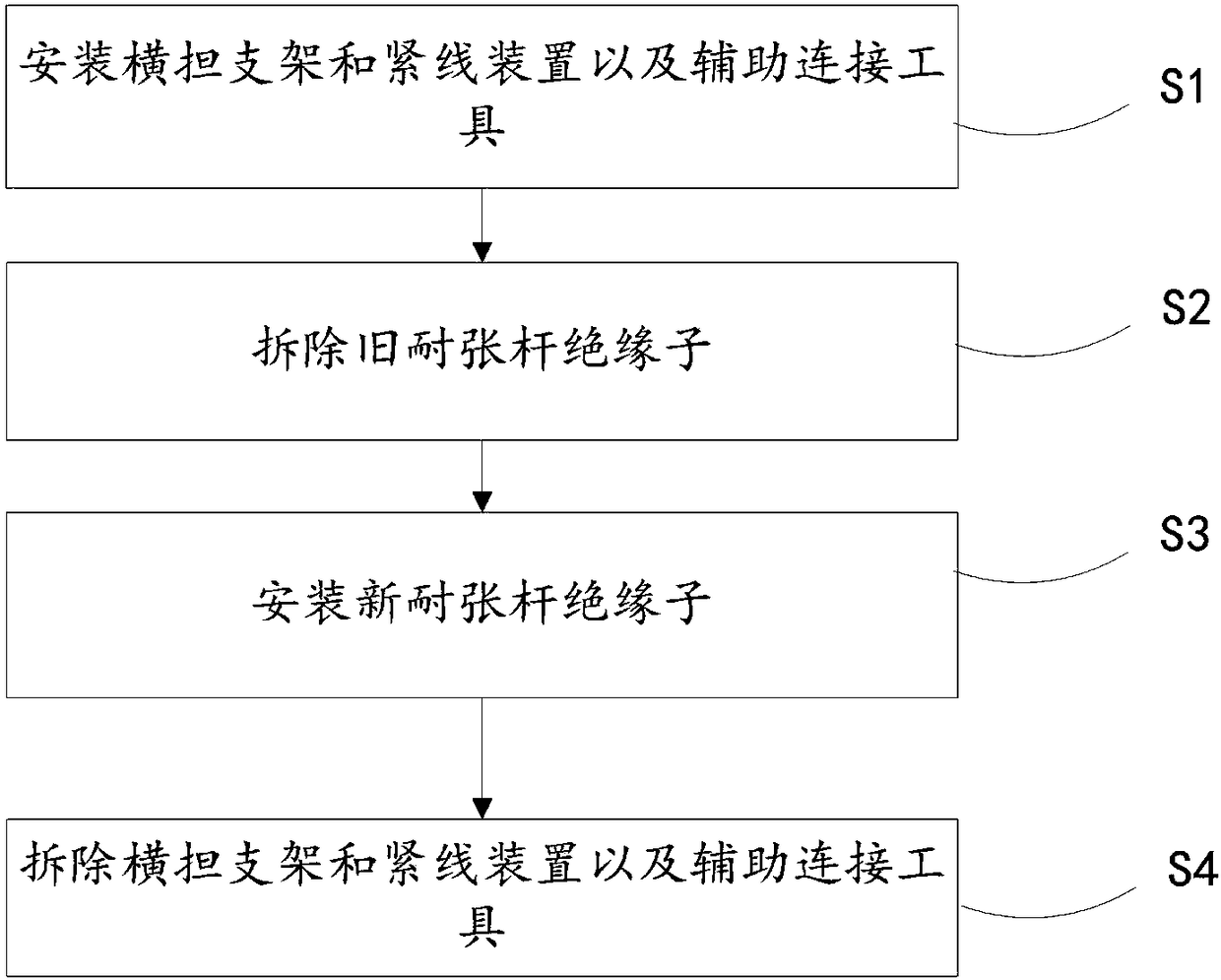

[0037] A method for live replacement of tension rod insulators, the method uses a 10kV line ground potential live replacement device for tension rod insulators, such as figure 2 shown, including the following steps:

[0038] S1: Install the cross-arm bracket and tensioning device and auxiliary connection tools;

[0039] S2: Remove the old tension bar insulators;

[0040] S3: Install new tension bar insulators;

[0041] S4: Remove the cross-arm bracket, wire tightening device and auxiliary connection tools;

[0042] In addition, it also includes routine steps before dismantling and installation, such as: installing on-site safety facilities; checking and testing whether tools and materials are complete; operators arriving at live working stations;

[0043] Conventional steps after dismantling and installation in the past: For example, the operator exits the live work station; cleans up the site, counts tools; and summarizes the work.

[0044] Preferably, in step S1, the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com