Automatic sorting system and technology based on real-time replenishing and tobacco carton intensive caching

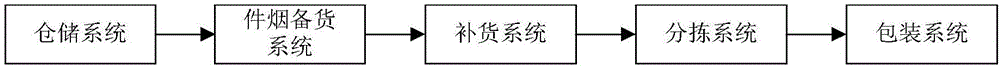

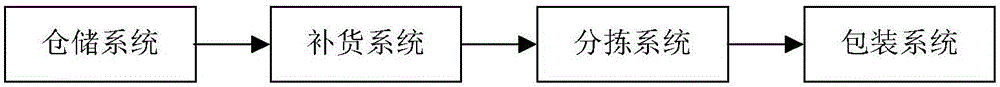

The technology of an automatic sorting system and a buffering system is applied in the technical field of the cigarette replenishment link and sorting link of the tobacco logistics distribution center, and can solve the problems of high equipment investment cost, inconvenient maintenance and repair, and large area of the stocking system. , to achieve the effect of saving equipment investment, improving operation efficiency and simplifying operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

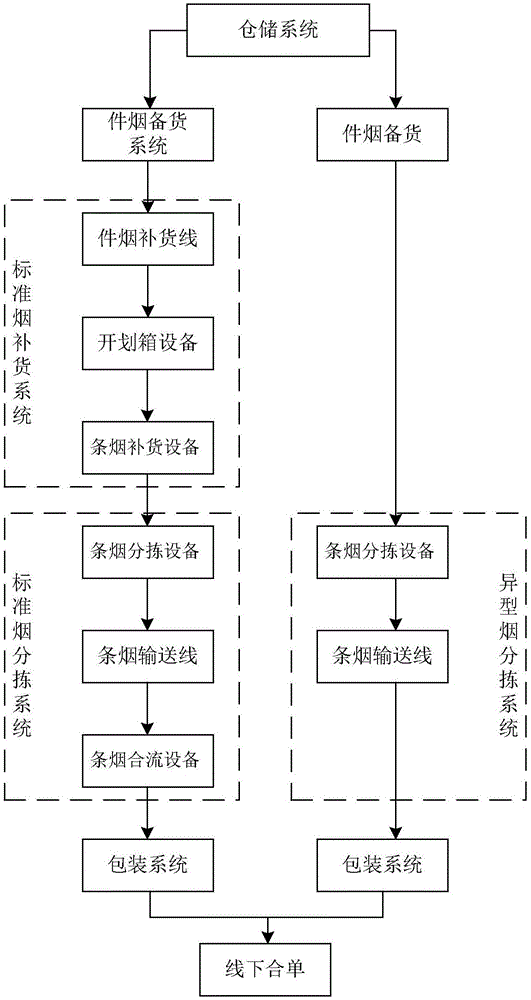

[0052] Example: as image 3 Shown is the composition diagram of the system of the present invention; by using the high-density storage system 7 for cigarettes to increase the storage capacity of cigarettes 6, the system for stocking up cigarettes is canceled, and the tedious and repetitive operation processes such as in and out of storage are reduced.

[0053] Such as Figure 4 Shown is the process flow chart of the present invention. All standard cigarettes and most special-shaped cigarettes are directly transported to the box opening system 4 through the cigarette replenishment conveyor line in a tray / batch, and the automatic box opening system 4 completes the automatic box opening operation. Realize the separation of cigarettes 1 and stacks of cigarettes, and the stacks of cigarettes produced after unpacking are converted into continuous single-layer cigarettes 6 through the stack-shaped conversion equipment, and are transported to the stack of cigarettes through the cigar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com