Aluminum tube and method for manufacturing same

A manufacturing method and technology of aluminum tubes, applied in the direction of coating, etc., can solve problems such as weak impact resistance, decreased adhesion, and increased production costs, and achieve the effects of reducing manufacturing costs, simplifying the coating process, and reducing fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be specifically described based on preferred embodiments of the present invention shown in the accompanying drawings.

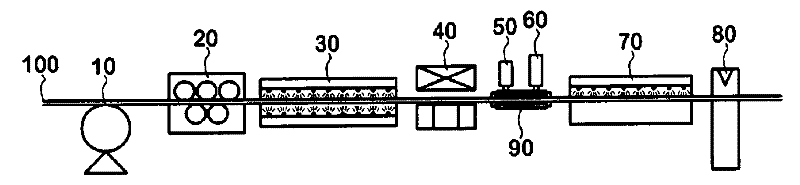

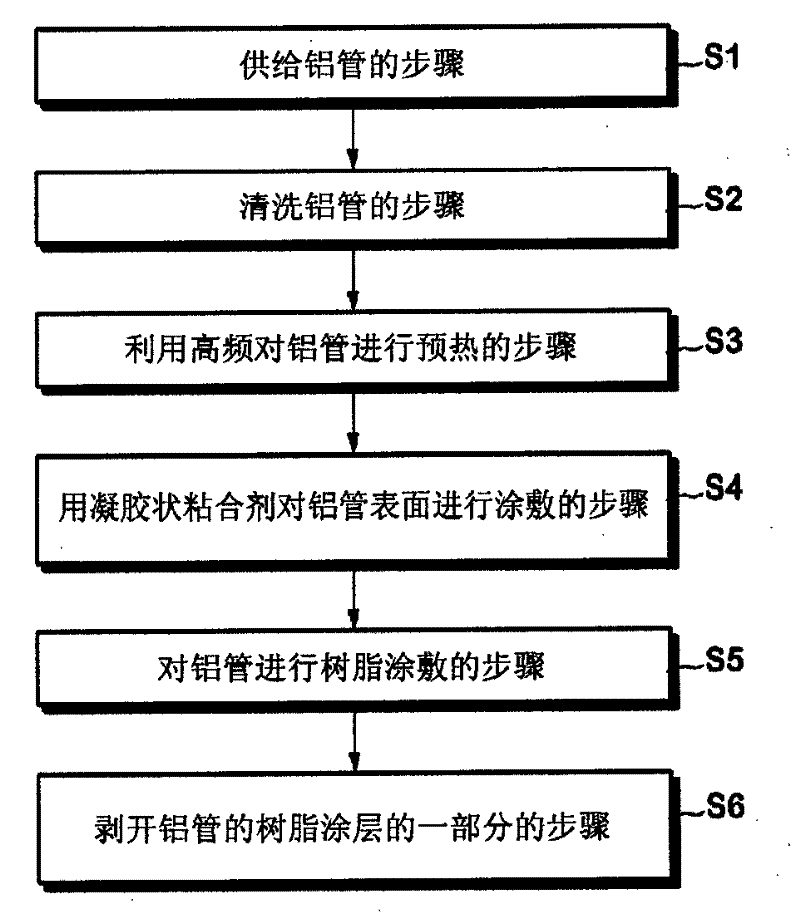

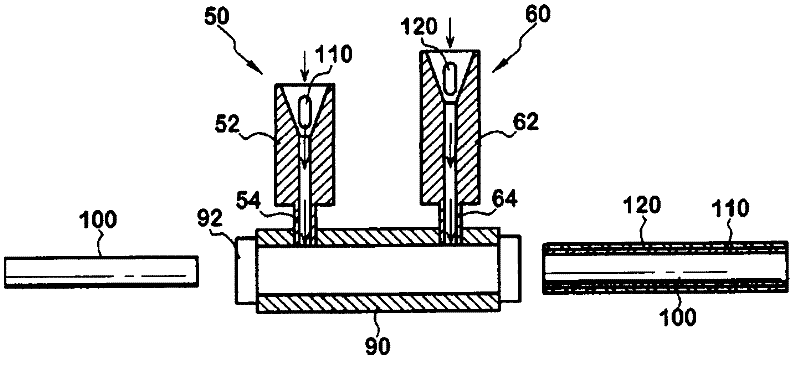

[0027] figure 1 is a structural diagram of the aluminum tube manufacturing method, figure 2 is a flowchart of the aluminum tube manufacturing method, image 3 It is a figure showing the state in which the adhesive and resin of the present invention are applied to an aluminum pipe, Figure 4 It is a cross-sectional view of the aluminum pipe of the present invention.

[0028] First, refer to Figure 1 to Figure 2 , specifically explain the aluminum pipe 100 of the present invention and its manufacturing method.

[0029] Such as figure 2 As shown, the manufacturing method of the aluminum tube 100 of the present invention includes the following steps: a supply step S1 of supplying the aluminum tube 100; a high-frequency preheating step S3 of preheating the above-mentioned aluminum tube 100 by using high freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com