Method and device for the dry forming of a fibre web

A fiber web and fiber technology is applied in the field of devices implementing the method to achieve the effect of suppressing the reverse effect and avoiding the turbulent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

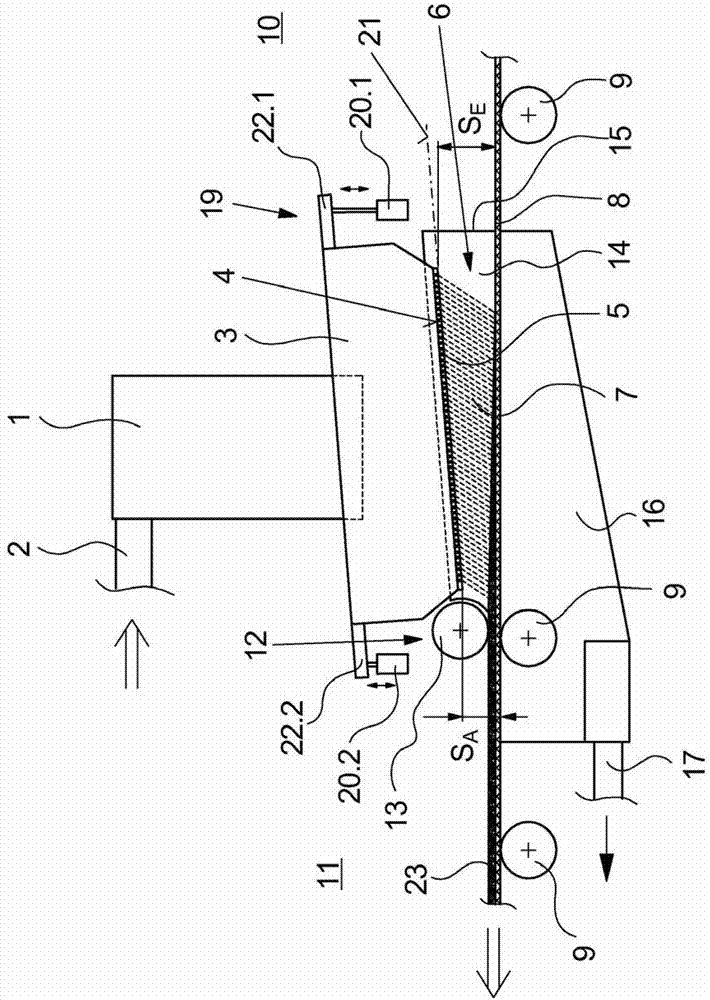

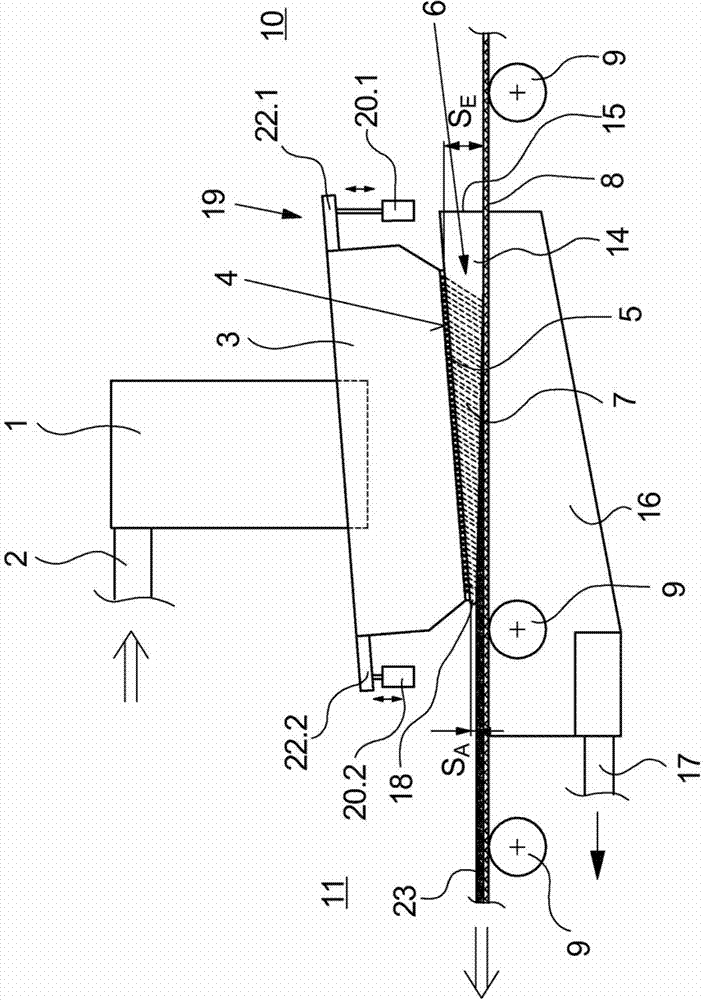

[0030] exist figure 1 A first exemplary embodiment of the device according to the invention for carrying out the method according to the invention is schematically shown in . This exemplary embodiment shows a mixing chamber 1 which is connected via a fiber inlet 2 to a fiber feed (not shown here). The fiber inlet 2 may comprise one or more connections in order to introduce one or more fibers or fiber mixtures into the mixing chamber 1 with an air flow. The mixing chamber 1 is connected on the bottom side to the forming head 3 . The forming head 3 has a plurality of means, not shown in detail here, for distributing the fibers or the fiber mixture and for discharging the fibers or the fiber mixture uniformly as a fiber stream via forming outlets 4 formed on the bottom surface. The shaping outlet 4 preferably has a plurality of sieve plates 5 . The distribution within the forming head is preferably achieved here by means of a plurality of driven blades (as is known, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com