Control device for continuously variable transmission for use in vehicles

A technology of continuously variable transmission and control device, which is applied in the direction of transmission, transmission control, components with teeth, etc., and can solve problems such as belt slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

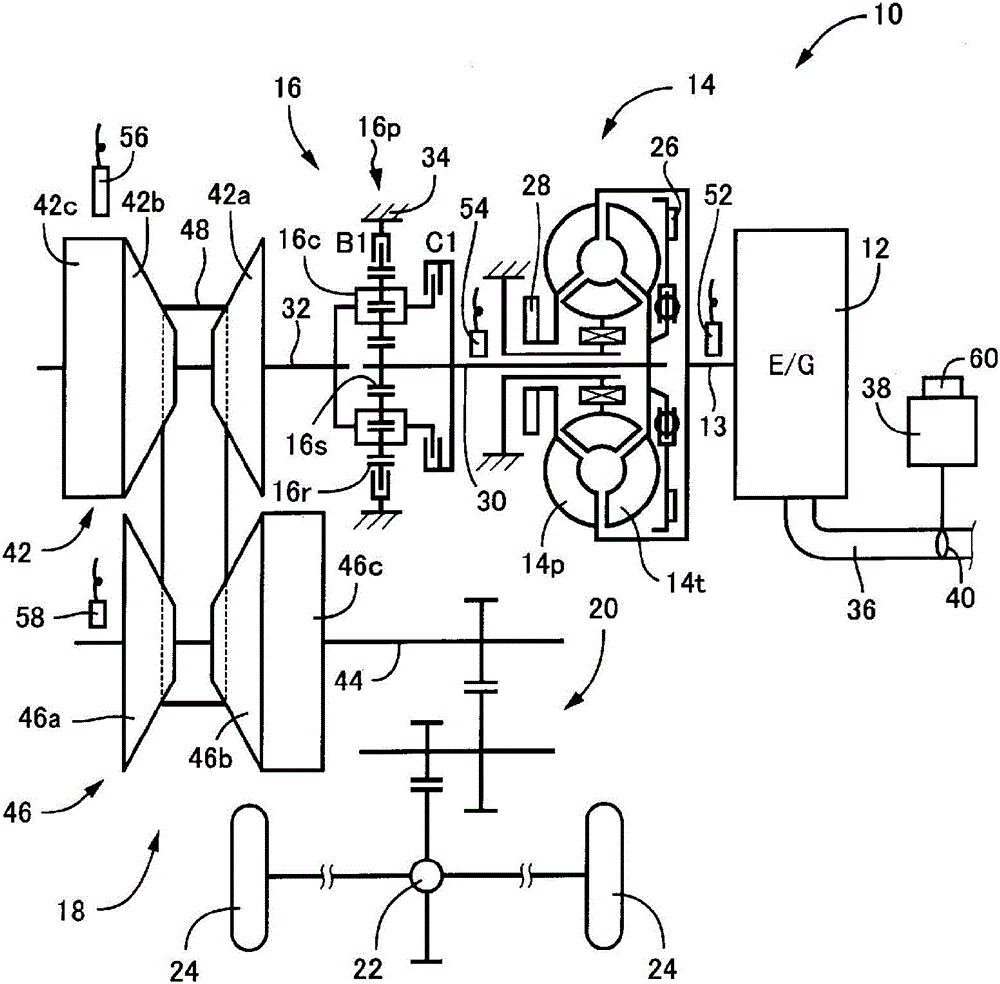

[0035] figure 1 It is a figure explaining the schematic structure of the power transmission path from the engine 12 to the drive wheel 24 which comprises the vehicle 10 to which this invention is applied. exist figure 1 Among them, for example, the power generated by the engine 12 used as a driving force source for traveling passes sequentially through a torque converter 14 as a fluid transmission device, a forward and reverse switching device 16, and a belt-type continuously variable transmission as a vehicle continuously variable transmission ( Hereinafter, a continuously variable transmission (CVT) 18 , a reduction gear unit 20 , a differential gear unit 22 , and the like transmit transmission to left and right drive wheels 24 .

[0036] The torque converter 14 has a pump impeller 14p connected to the crankshaft 13 of the engine 12, and a turbine 14t connected to the forward / reverse switching device 16 via a turbine shaft 30 corresponding to an output side member of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com