Wavefront optimized progressive lens

A progressive lens and lens technology, applied in the direction of glasses/safety glasses, glasses/goggles, equipment for testing eyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

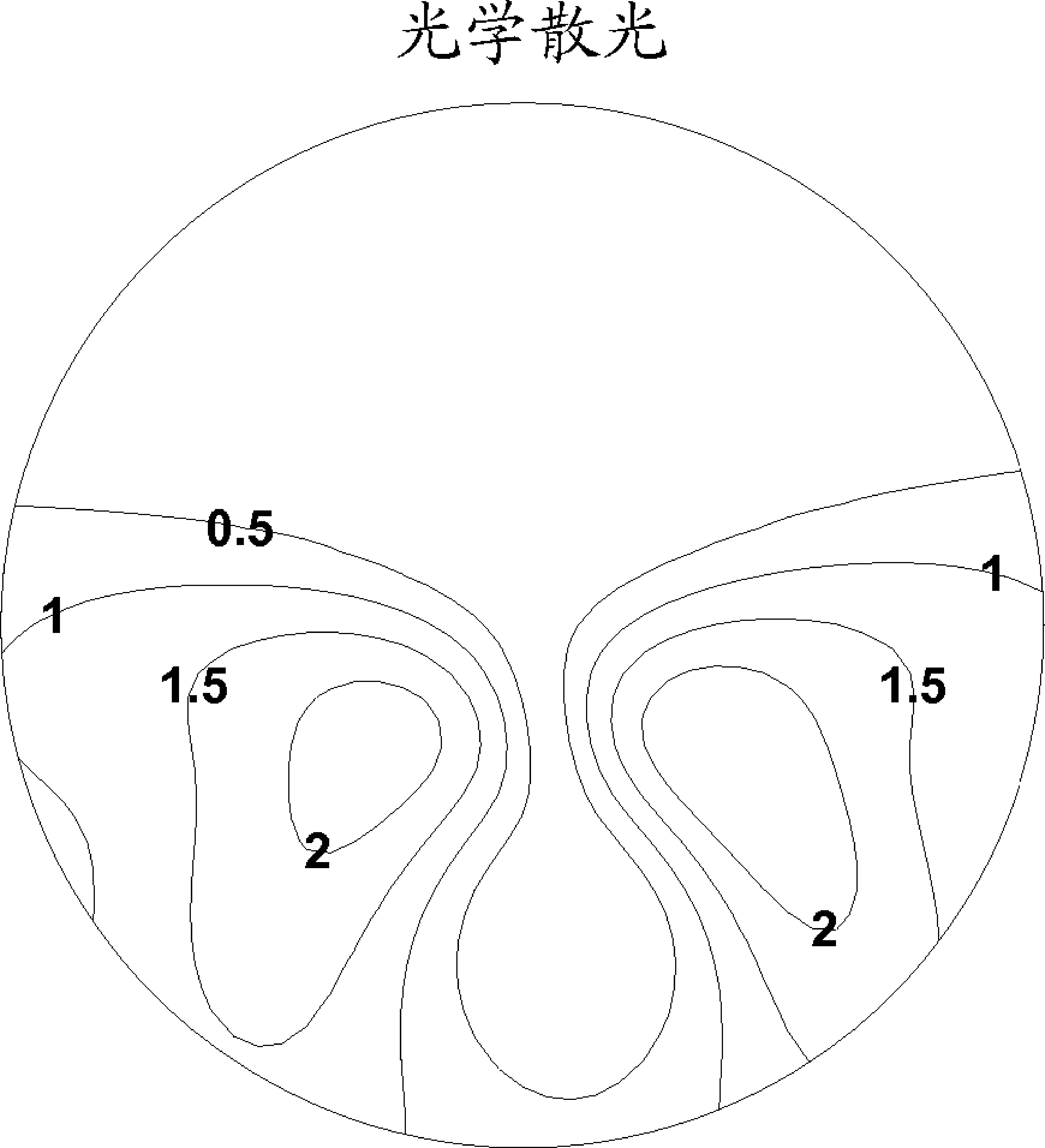

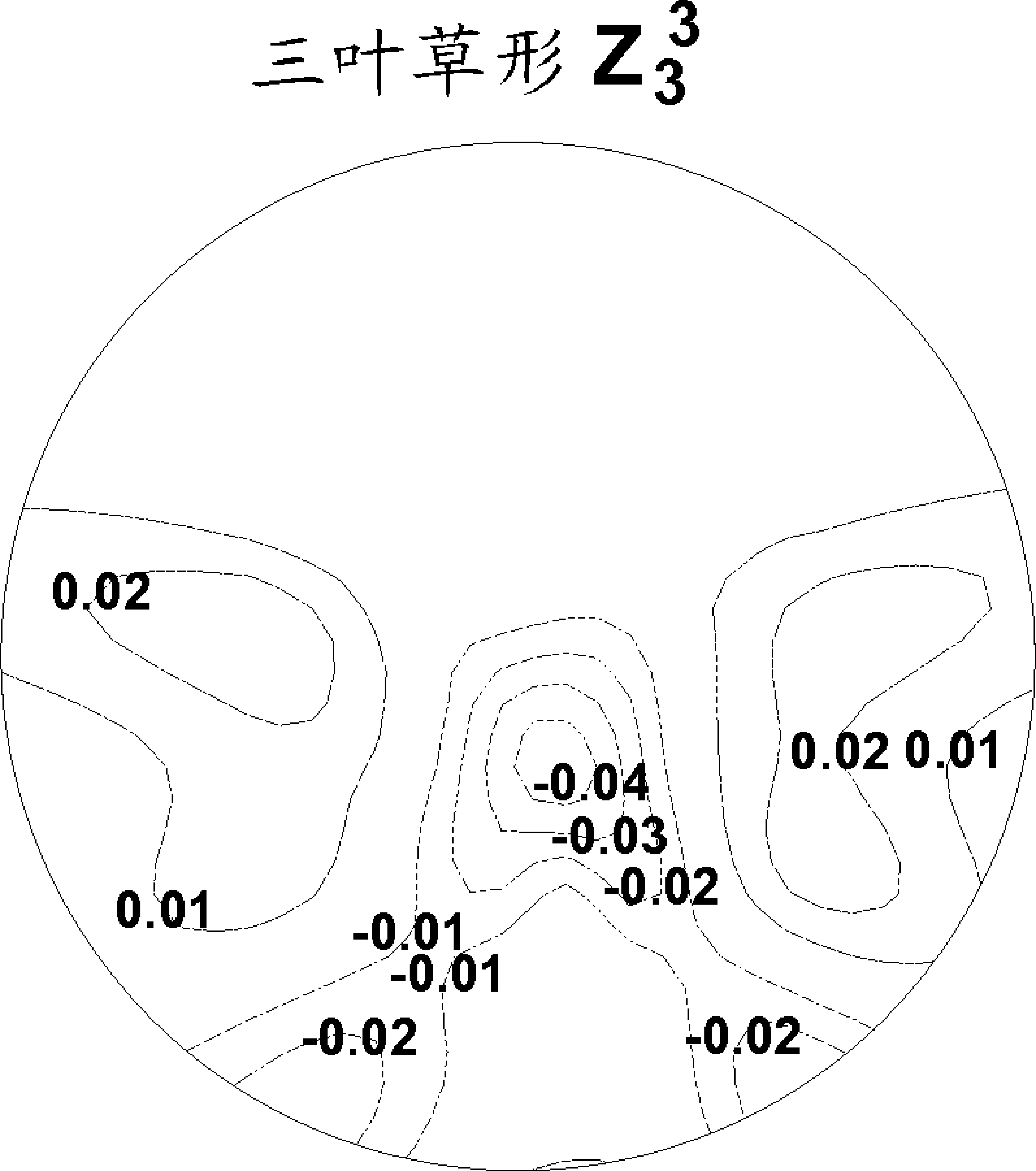

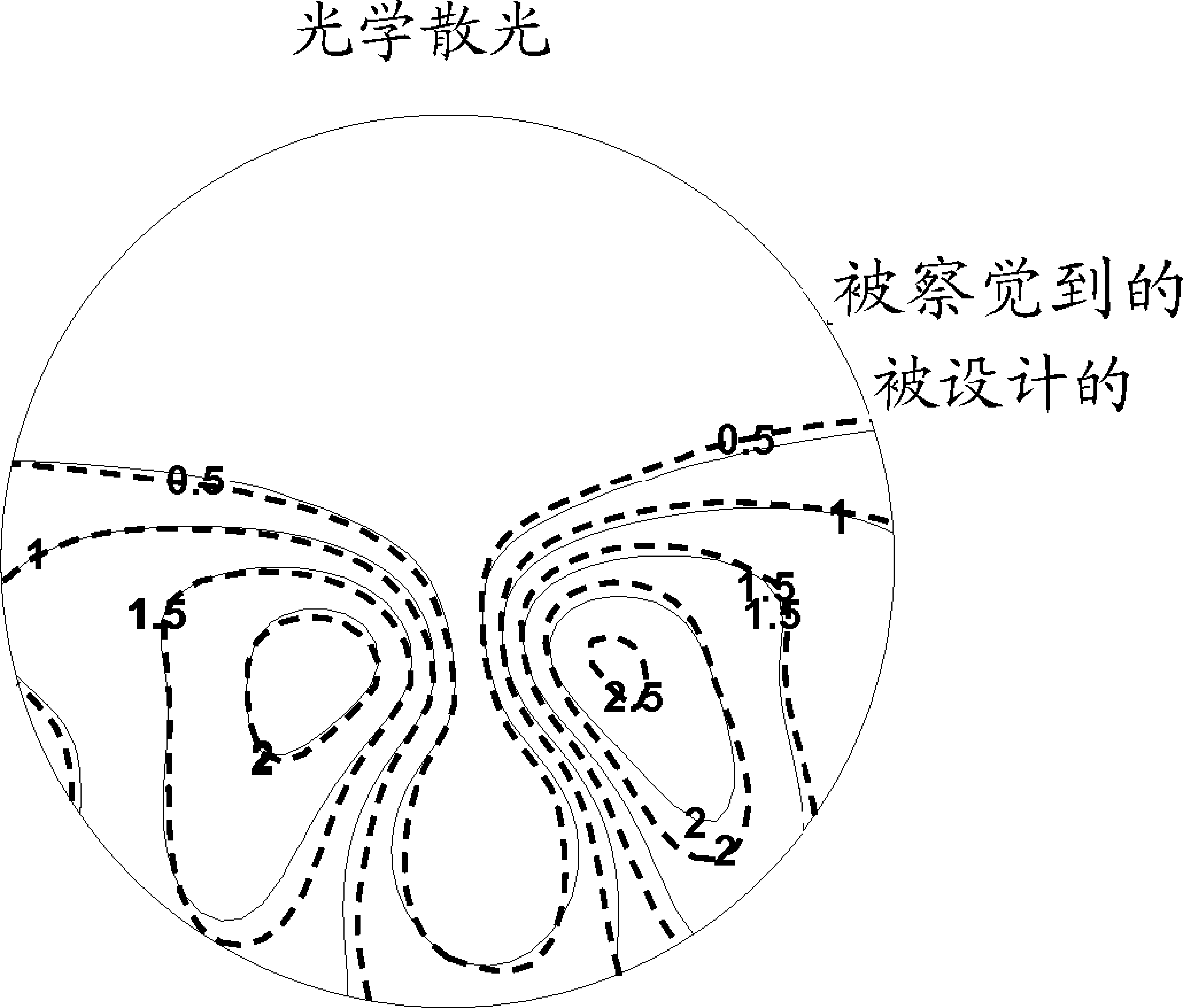

[0044] In general, there are numerous methods of mathematically defining PAL surfaces. The basic design parameters described above can be defined directly in equations, or derived experimentally by adjusting the relevant parameters, according to the mathematical functions used by the lens designer to create the initial surface. If these functions are complex enough to produce a sufficiently adequate and well-behaved progressive lens surface, then that surface may be suitable for use without any significant refining.

[0045] However, the "starting" surface (or surfaces) is generally optimized to minimize the difference between the optical performance of the lens and the target optical performance. This is usually done numerically using lens design software that attempts to find the physical surfaces that meet the ideal optical performance requirements of the lens design as closely as possible. Basically, the software minimizes the difference between the actual parameter value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com