Heald polishing device

A technology of polishing device and heald wire, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of poor effect, fast and slow deburring and polishing, and achieve good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

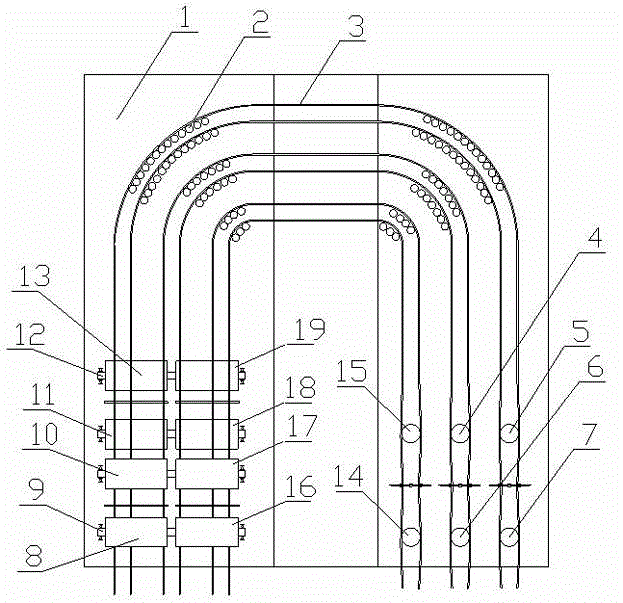

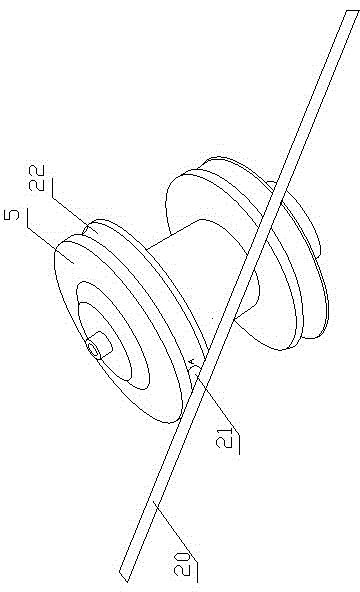

[0015] As shown in the figure, the present invention comprises frame 1, and frame 1 is provided with polishing grinding wheel group, upper polishing wheel group, lower polishing wheel group, reversing wheel group and diverting pulley group.

[0016] The polishing wheel set is set at the front of the frame 1, the upper polishing wheel set is set at the rear of the frame 1, the steering pulley set is set between the lower polishing wheel set and the polishing wheel set, and the reversing wheel set is set at the upper polishing wheel set and the lower buff set.

[0017] The polishing grinding wheel group comprises front row grinding wheels and rear row grinding wheels, and front row grinding wheels are three, are respectively grinding wheel 6, grinding wheel 7, grinding wheel 14, and front row grinding wheel also is three, are respectively grinding wheel 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com