A deburring device for deep processing water outlet metal castings on inner pipe surface

A metal casting and deburring technology, which is applied in the field of deburring devices for deep processing of water pipe metal castings on the surface of the inner pipe, can solve the problems of hand strain, reduce the rigidity of the water pipe, and fall off, and achieve the effect of improving the rigidity and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

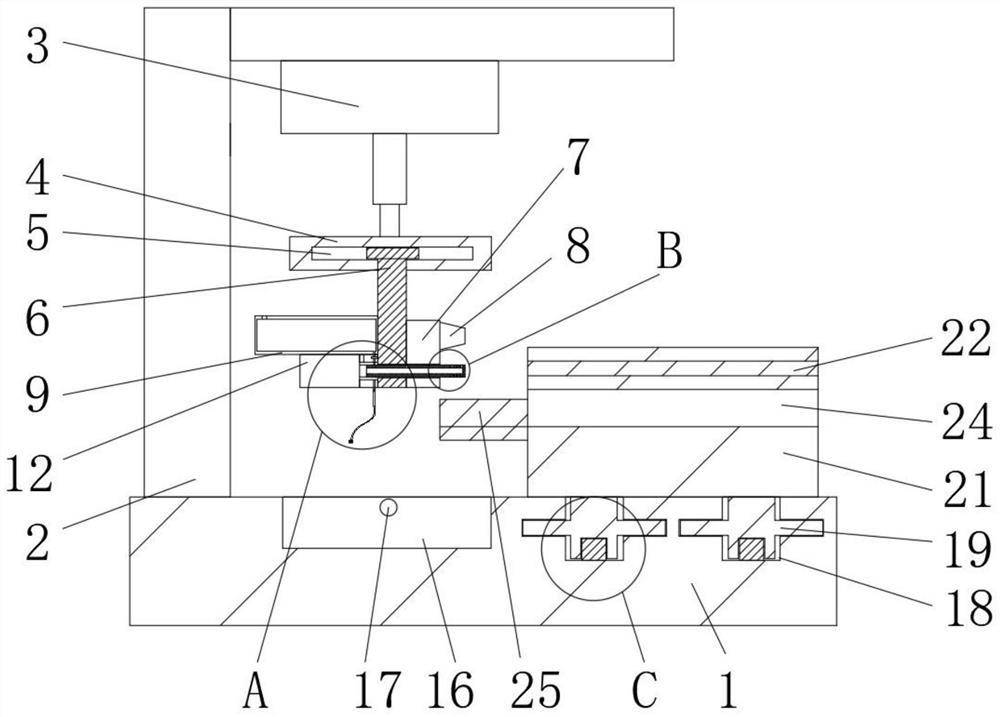

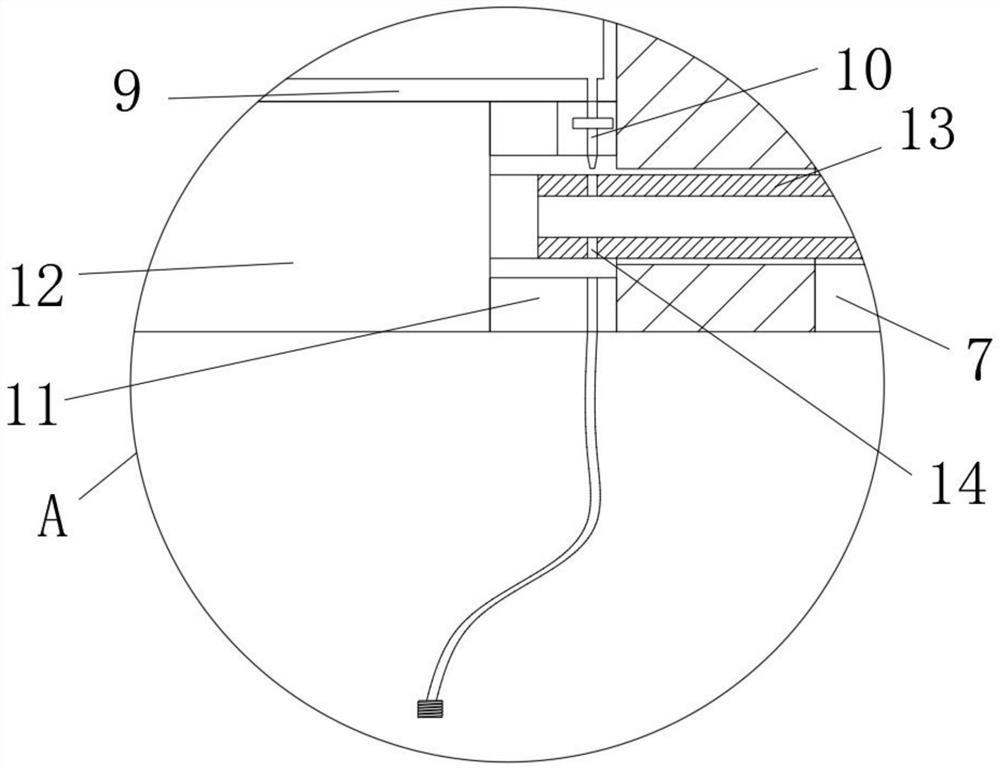

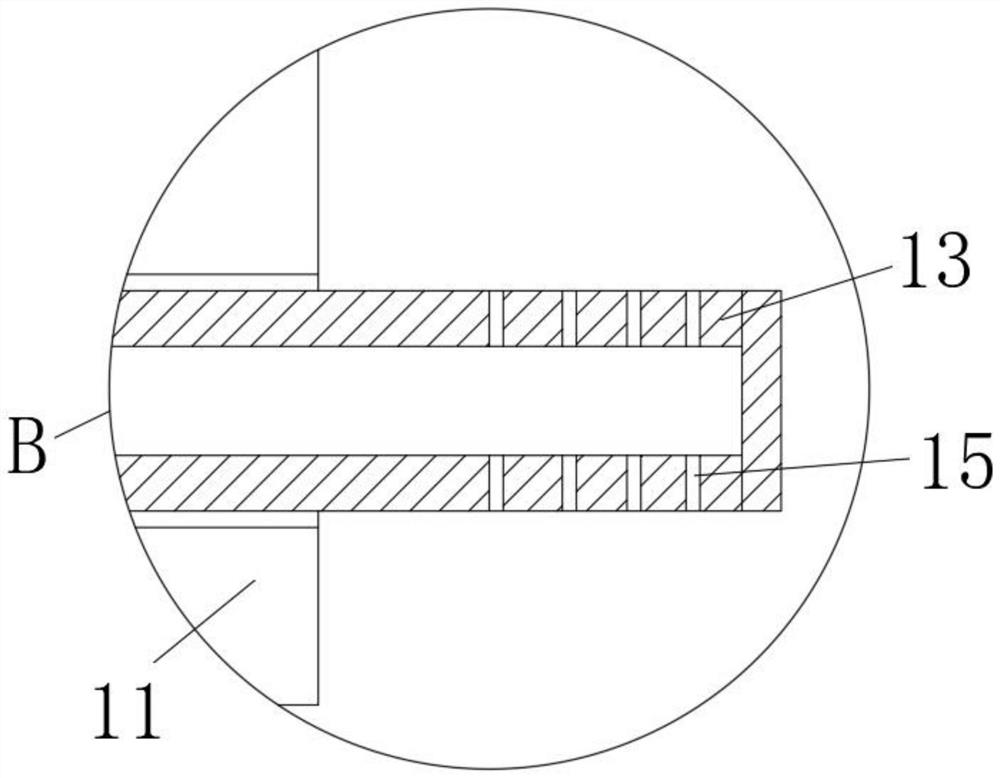

[0036] see Figure 1-6, a deburring device for deep-processing the surface of the inner pipe and outlet pipe metal castings, including an operation table 1, the upper end of the operation table 1 is fixedly connected with a fixed frame 2, and the lower end of the fixed frame 2 is fixedly connected with a cylinder 3, and the model of the cylinder 3 is set as SC63X25 The lower end of the cylinder 3 is connected with a telescopic rod 31, and the end of the telescopic rod 31 away from the cylinder 3 is fixedly connected with a connecting plate 4, the connecting plate 4 is provided with a first chute 5, and the first chute 5 is slidably connected with a slide plate 6, the first The height of the chute 5 matches the thickness of the slide plate 6 to prevent the slide plate 6 from slipping during work. The lower end of the slide plate 6 is fixedly connected with the first fixed block 7, and the end of the first fixed block 7 away from the slide plate 6 is fixedly connected with the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com