Insulation cover molding die at busbar overlapping part

A technology for forming molds and insulating covers, which is applied in the field of forming molds, can solve the problems of messy busbar chambers, fixed clamping of insulating covers on metal busbars, slipping off of metallic busbars 72 or bolt caps 73, etc., and achieves tightness of metal busbars Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

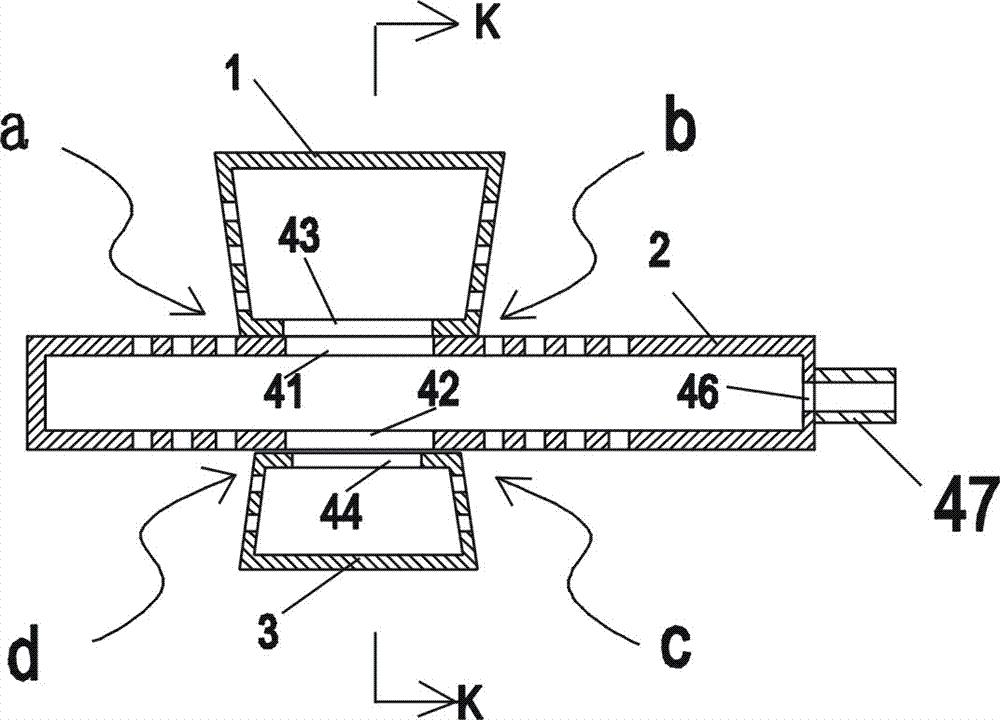

[0059] In the second embodiment, there are three hollow metal boxes welded together, the structure of the upper metal box 1, the middle metal box 2, and the lower metal box 3 is exactly the same as that of the first embodiment, except that In addition, the second embodiment is also equipped with an upper widening die sleeve 5 and a lower widening die sleeve 6, such as Figure 18 shown. The upper widening mold cover 5 is provided with five side walls, namely the top wall 55, the bottom wall 56, the right wall 54, the front wall 51, and the rear wall 52 of the upper widening mold cover 5, and the lower widening mold cover 6 is also provided with Five side walls, i.e. the top wall 65, the bottom wall 66, the right wall 64, the front wall 61, and the rear wall 62 of the lower widening die sleeve 6.

[0060] Figure 21 , Figure 23 As shown, the left side of the upper widening die cover 5 is hollowed out, and the left side of the lower widening die cover 6 is hollowed out; Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com