Stator punching piece of motor with small notch and coil instillation method thereof

A notch motor and stator punching technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of difficult stator punching coil installation, low efficiency of coil assembly work, increased motor loss, etc., to achieve assembly High efficiency, easy installation, and the effect of increasing magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

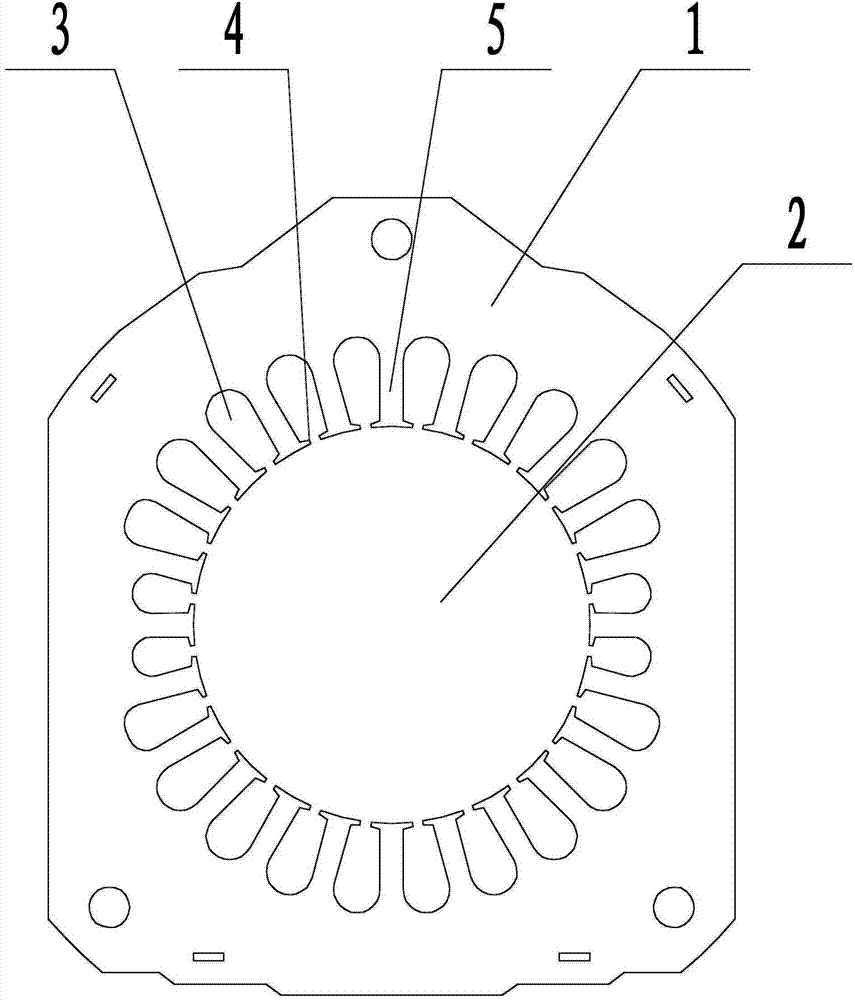

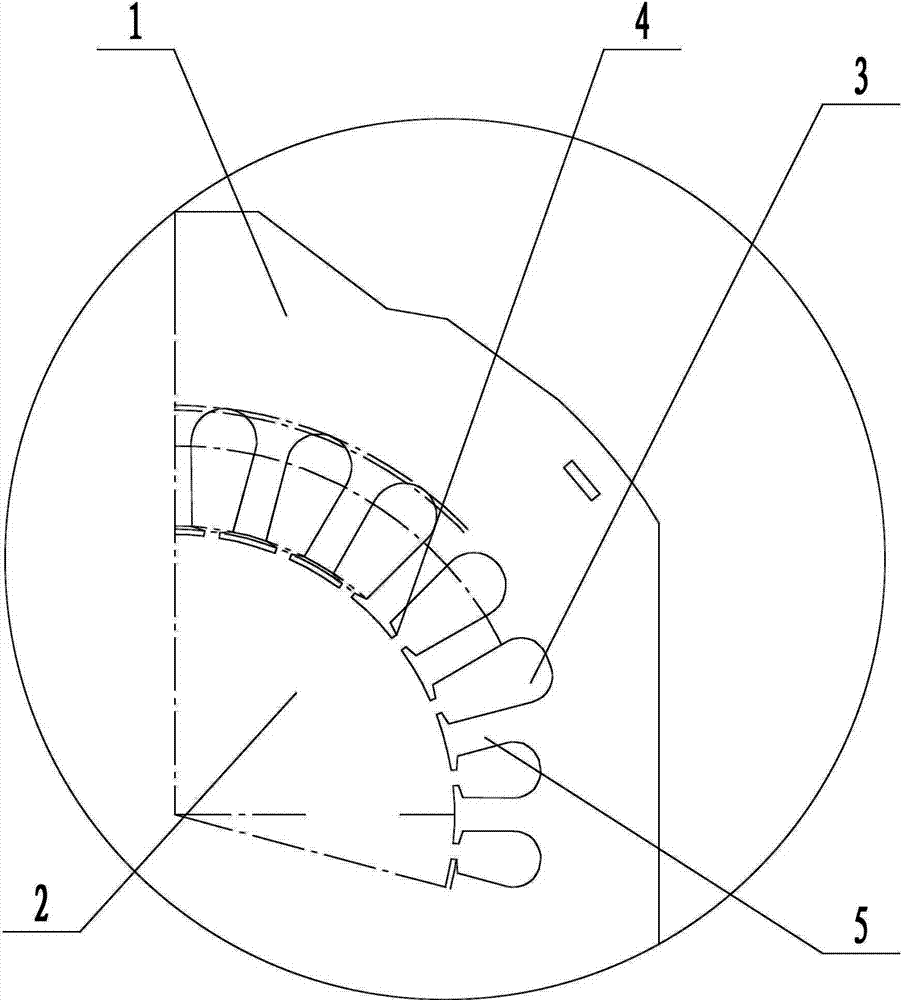

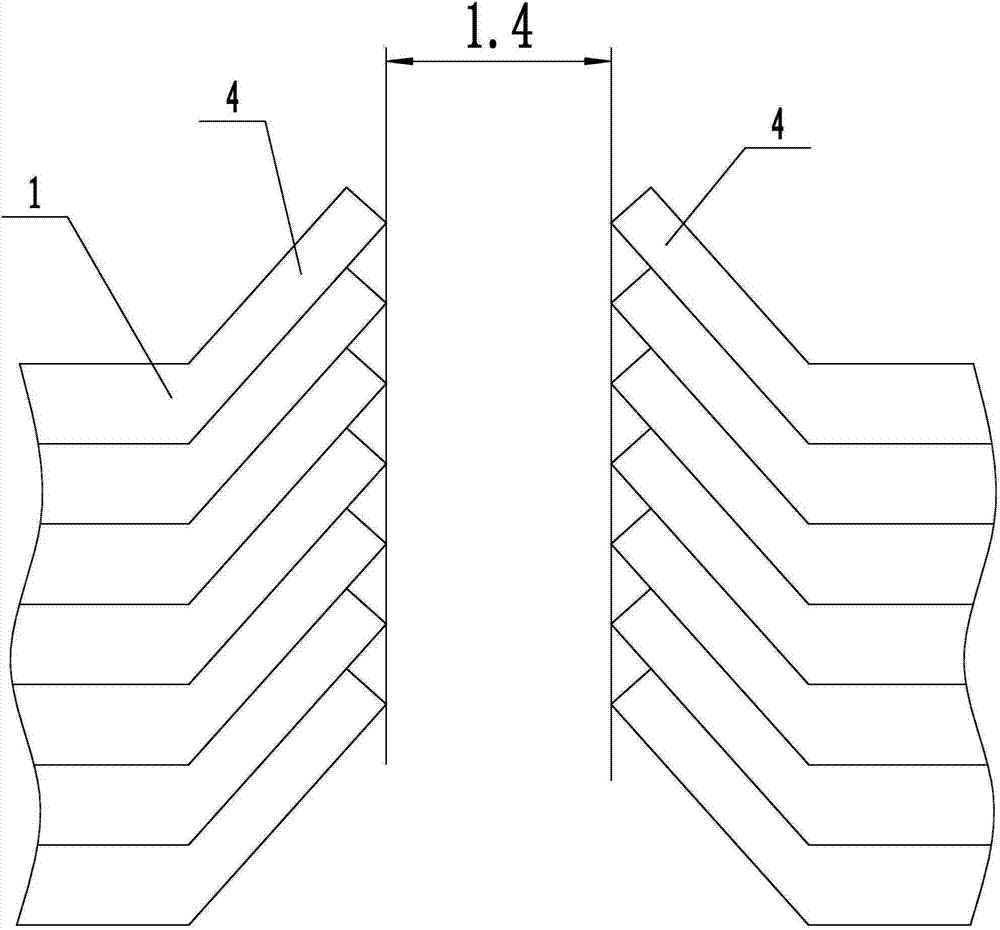

[0027] Embodiment 1: A stator punching piece of a small slot motor (see attached figure 1 , attached figure 2 ), including the punching body 1, a circular through hole 2 is provided in the middle of the punching body, and several wiring grooves 3 are arranged on the side wall of the through hole along the circumference of the through hole, and the wiring grooves are arranged along the circumference of the through hole. Evenly distributed, the width of the wiring trough gradually increases from the notch to the bottom of the trough, and the bottom of the wiring trough is in a concave arc-shaped structure. Both edge positions of the wire slot notch on the punching body are provided with extension ribs 4, and the extension ribs and the punching body are in one structure, and the two extension ribs arranged in the same notch are oppositely arranged and a gap is provided between them. The width of the gap between the two extension ribs arranged in the same notch is 0.1mm-1.0mm. I...

Embodiment 2

[0029] Embodiment 2: A stator punch of a small-slot motor, the structure of which is the same as that of Embodiment 1. A coil installation method for stator punching of a small-slot motor, the steps of which are similar to those in Embodiment 1. The wiring trough arranged around the through hole divides the punch body near the through hole into several separators 5, and the separator is set between two adjacent wire troughs. In the second step, a special high The punching die bends the separator vertically upwards, and in the fourth step, a special high punching die is used to flatten the separator before flattening the stacked extension ribs. Other steps are the same as in Example 1. The vertical bending of the separator increases the aperture of the through hole, and the width of the gap between the two relative extension ribs also increases accordingly, which is more convenient when installing the coil.

Embodiment 3

[0030]Embodiment 3: A stator punch of a small-slot motor, the structure of which is the same as that of Embodiment 1. A coil installation method for stator punching of a small-slot motor, the steps of which are similar to those in Embodiment 1. In this embodiment, one of the two adjacent extension ribs is bent upward and the other is bent downward, and all the extension ribs are bent upward and downward alternately, and the vertical bending angle of the extension rib is 60 degrees. Other steps are the same as in Example 1. One of the two adjacent extension ribs is bent upwards and the other is bent downward. After all the stator punches are stacked together, the slot width of the slots of the uppermost and lowermost stator punches is larger than that of the two adjacent extension ribs. The width of the notch opening of the wire-loading slot formed by bending down is set by bending, so that the process of installing the coil to the wire-loading slot is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com