Facility and method for manufacturing tread-reinforcing breaker plies with a device for turning over bead flippers while flat

A technology to strengthen the ply and equipment, applied in the direction of transportation, packaging, tire, application, etc., can solve the problems of frequent maintenance, loss of precision, loss of raw materials, etc., and achieve the effect of saving maintenance operations, reducing production cycle time, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

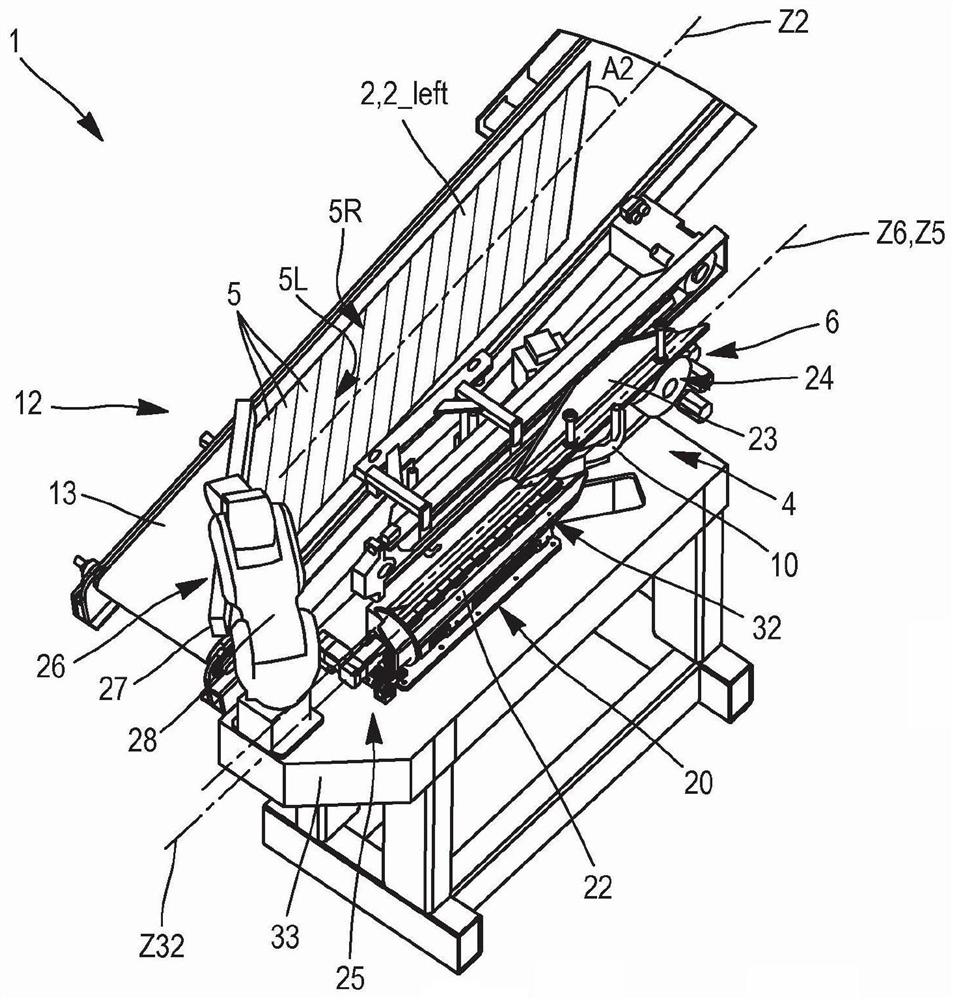

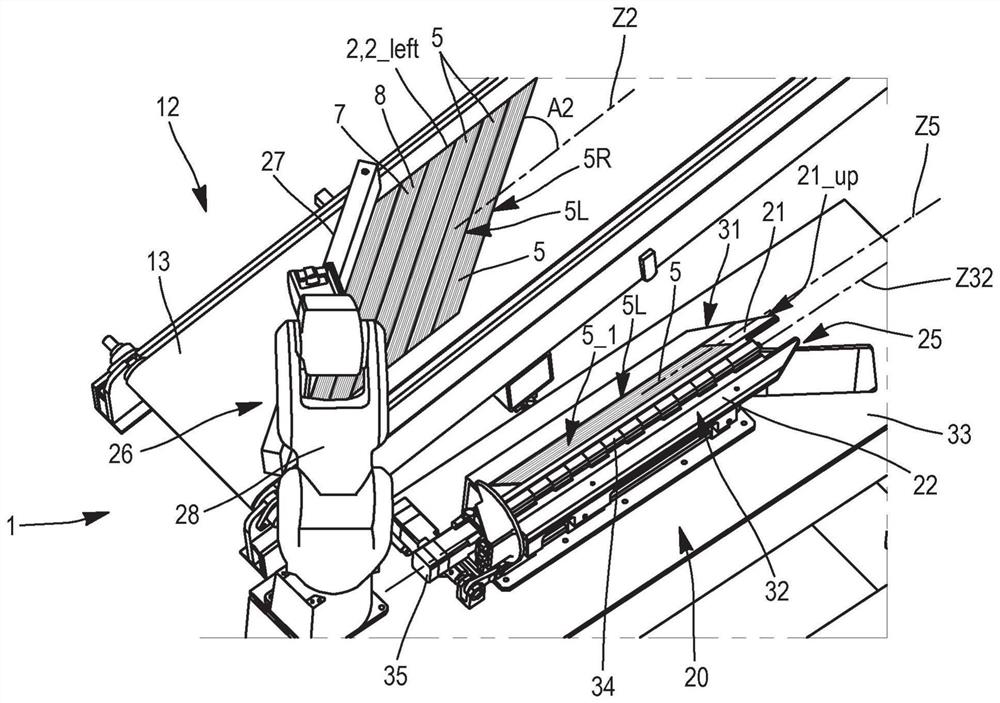

[0042] The invention relates to a plant 1 for manufacturing a reinforcing ply 2 .

[0043] This reinforcing ply 2 is intended to reinforce the structure of a tire 3 and more particularly of a tire 3 intended for wheeled vehicles.

[0044] Such a tire 3 may be solid, or have a honeycomb structure (commonly used for puncture-proof tyres), or preferably, be a pneumatic tyre, without departing from the scope of the present invention.

[0045] Preferably, as Figure 11 As shown, the reinforcing ply 2 may be intended for use in the composition of the "cap body" of the tire 3, thereby reinforcing the structure of said pneumatic tire in the circumferential space contained between the carcass ply and the tread.

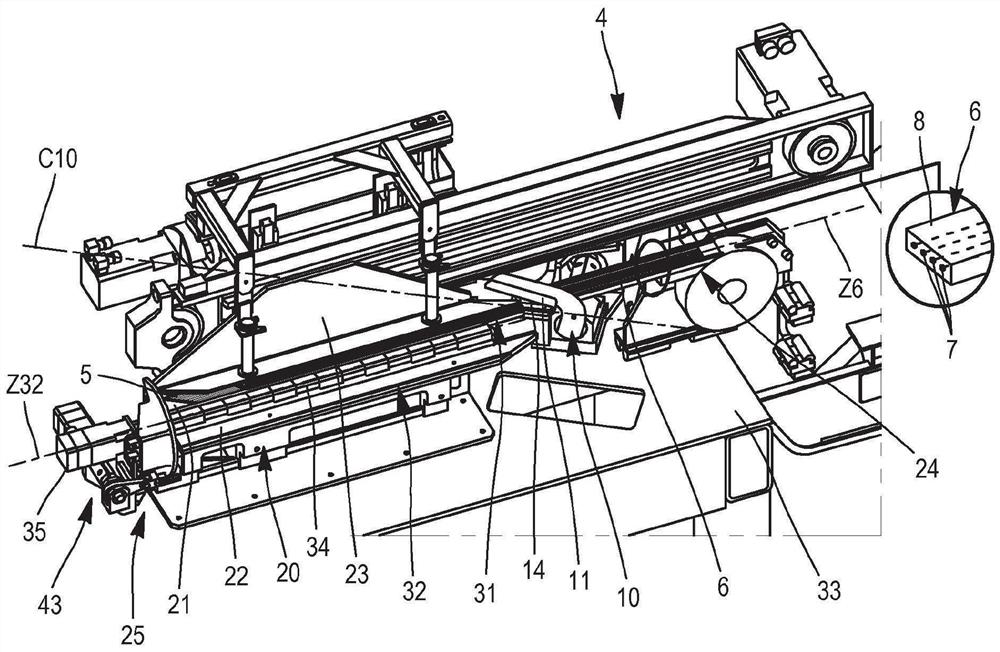

[0046] First, if figure 1 with figure 2 As shown, the apparatus comprises a preparation station 4 arranged to prepare a strip 5 by cutting a strip called a “straight wire ribbon” 6 .

[0047] As known per se, said straight thread band 6 is formed by a plurality of reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com