Round smooth plating printing press and operating procedure of the same

A working method and technology of printing presses, which are applied in the directions of rotary flat presses, printing presses, printing, etc., can solve the problems of limited step distance between printing plates and printing plates, high cost, and the process cannot be carried out on the same machine at the same time, so as to shorten the time. Processing time, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

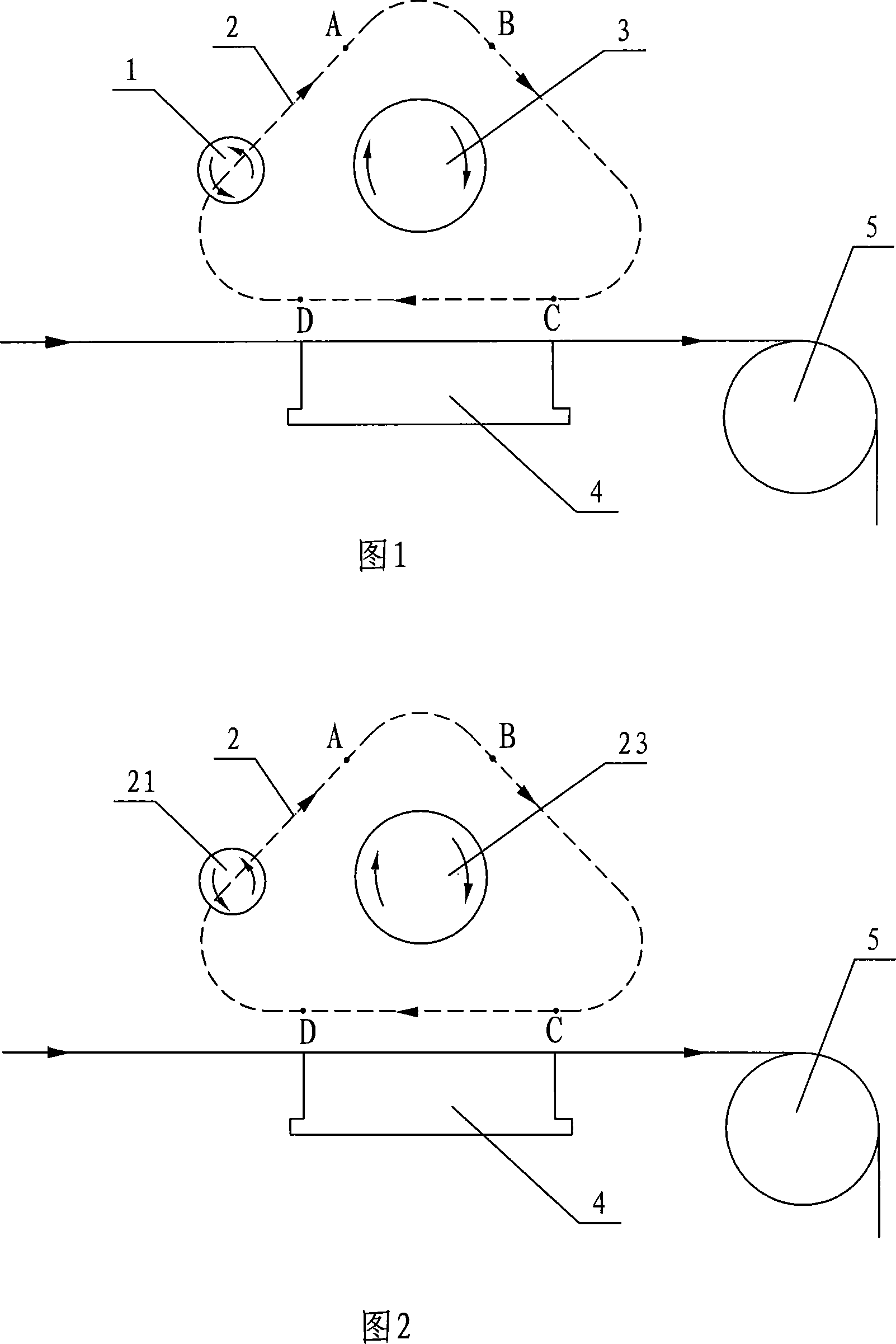

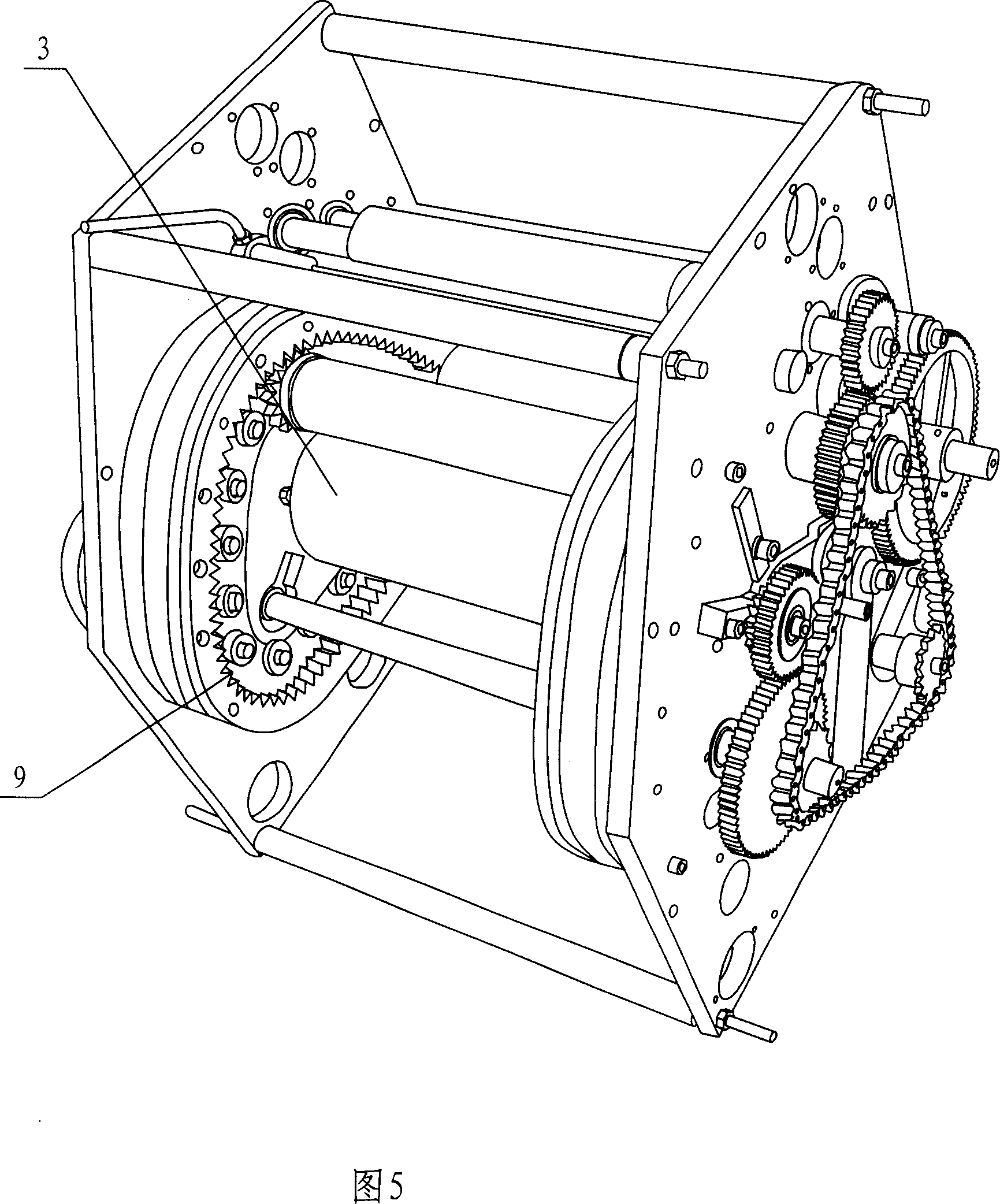

[0040] Referring to Fig. 1 and Fig. 4-Fig. 5, circular rails 2 are arranged symmetrically on the left and right sides of the circular flattening offset printing machine. The length of the arc-shaped ink section AB in the track 2 is equal to the circumference of the adhesive tape cylinder 1 , and the arc-shaped ink section AB is concentrically arranged with the printing plate cylinder 3 . The printing table 4 is arranged below the two rails 2, and the two ends of the printing plate cylinder 3 are respectively arranged in the middle of the left and right two rails. For transferring ink pattern or ink, the track 2 is provided with a straight printing section CD corresponding to the printing table 4 , and the length of the straight printing section CD is equal to the circumference of the printing plate cylinder 1 .

[0041] The track 2 is provided with a chain 7 connected to the output shaft of the drive motor, and the side of the track 2 is provided with an annular internal tooth...

no. 2 example

[0043] Referring to Fig. 2 and Fig. 10-Fig. 11, the plate cylinder 21 in the letterpress printing machine is arranged on the track 2, and the ink roller 23 is arranged in the middle of the track.

[0044] The rest are the same as the first embodiment and will not be repeated.

no. 3 example

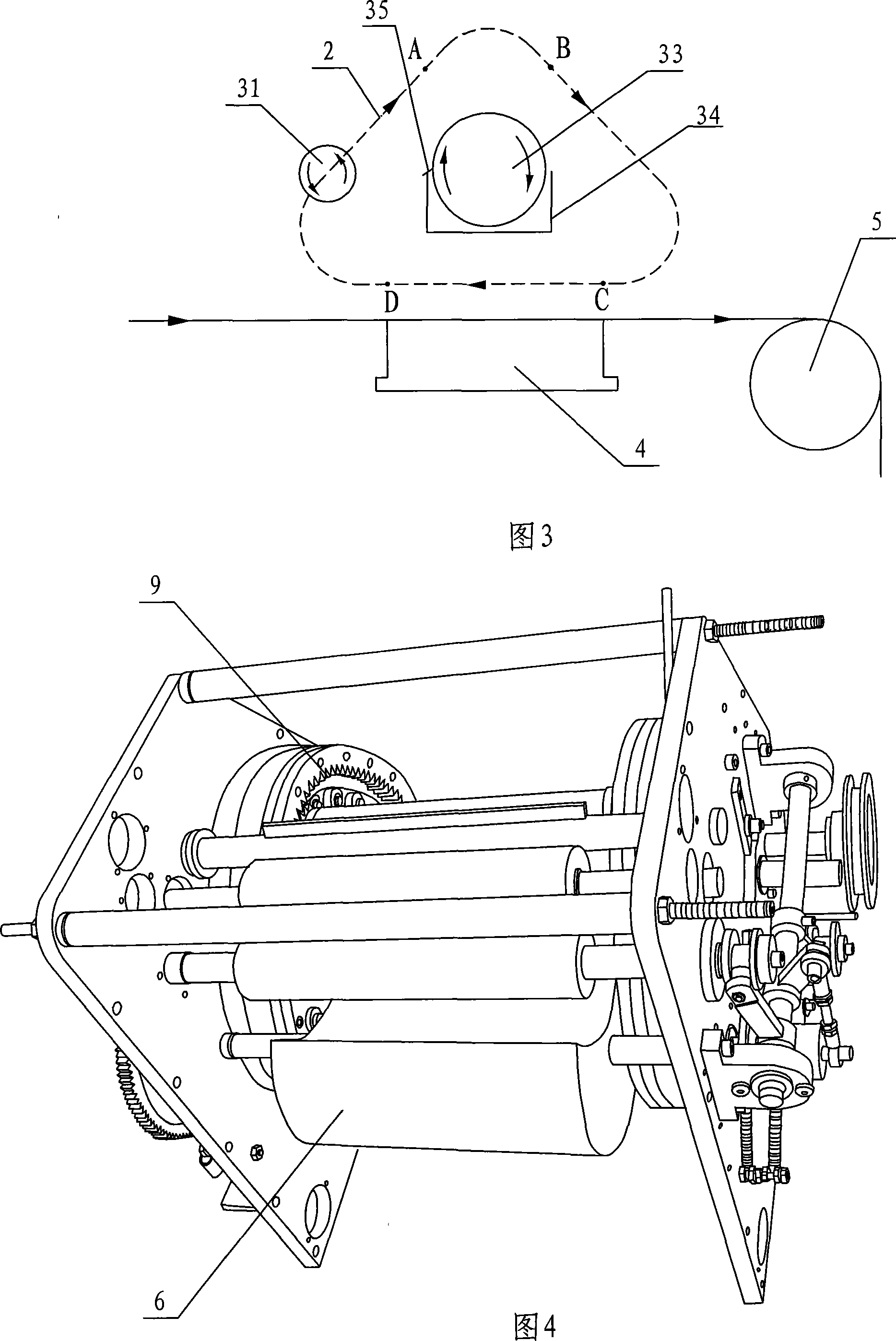

[0046] Referring to Fig. 3 and Fig. 10-Fig. 11, the plate cylinder 31 in the flexographic printing machine is arranged on the track 2, the anilox roller 33 is arranged in the middle of the track, the anilox roller is arranged in the ink tank 34, and the ink tank is provided with Squeegee 35, one end of the squeegee is in contact with the surface of the anilox roller.

[0047] The rest are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com