Manufacturing method of flexible composite material

A technology of composite materials and manufacturing methods, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as production process appearance defects, poor appearance, and obvious scratches on products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with example the present invention will be further described. However, these examples should not be used to interpret the limitation of the protection scope of the present invention. All equivalent transformations made without departing from the basic concept of the present invention belong to the protection scope of the present invention.

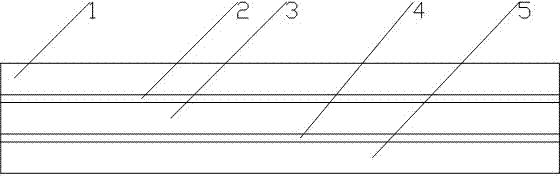

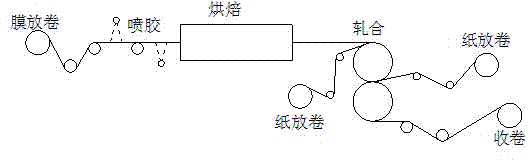

[0017] a. The substrate film (3) is unwound;

[0018] b. Spray a layer of polyurethane adhesive solution on both sides of the substrate film (3) after unwinding to form a polyurethane adhesive layer (2), (4) The suitable viscosity of the polyurethane adhesive is 13-25 seconds (4 cups of viscosity) , the amount of glue sprayed on both sides is 8-30g / m 2 ;

[0019] c. Bake the solvent at 100-160°C for 30-120 seconds.

[0020] d. The adhesive layer (2), (4) is hot-pressed and rolled together with the fiber paper (1), (5) respectively, and then processed and cut into finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com