Method for manufacturing copper cylinder through pattern transfer

A technology of pattern transfer and production method, which is applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of increasing roughness, solving appearance defects, and enhancing bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

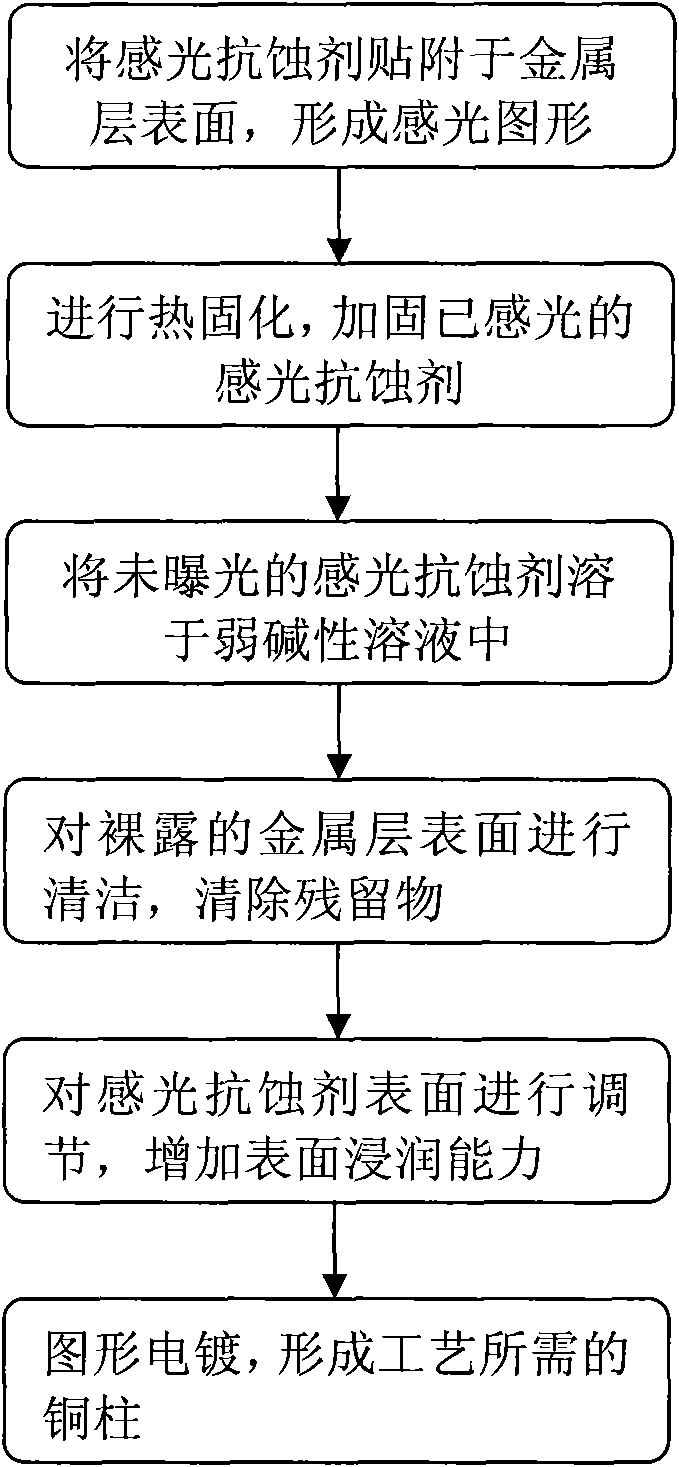

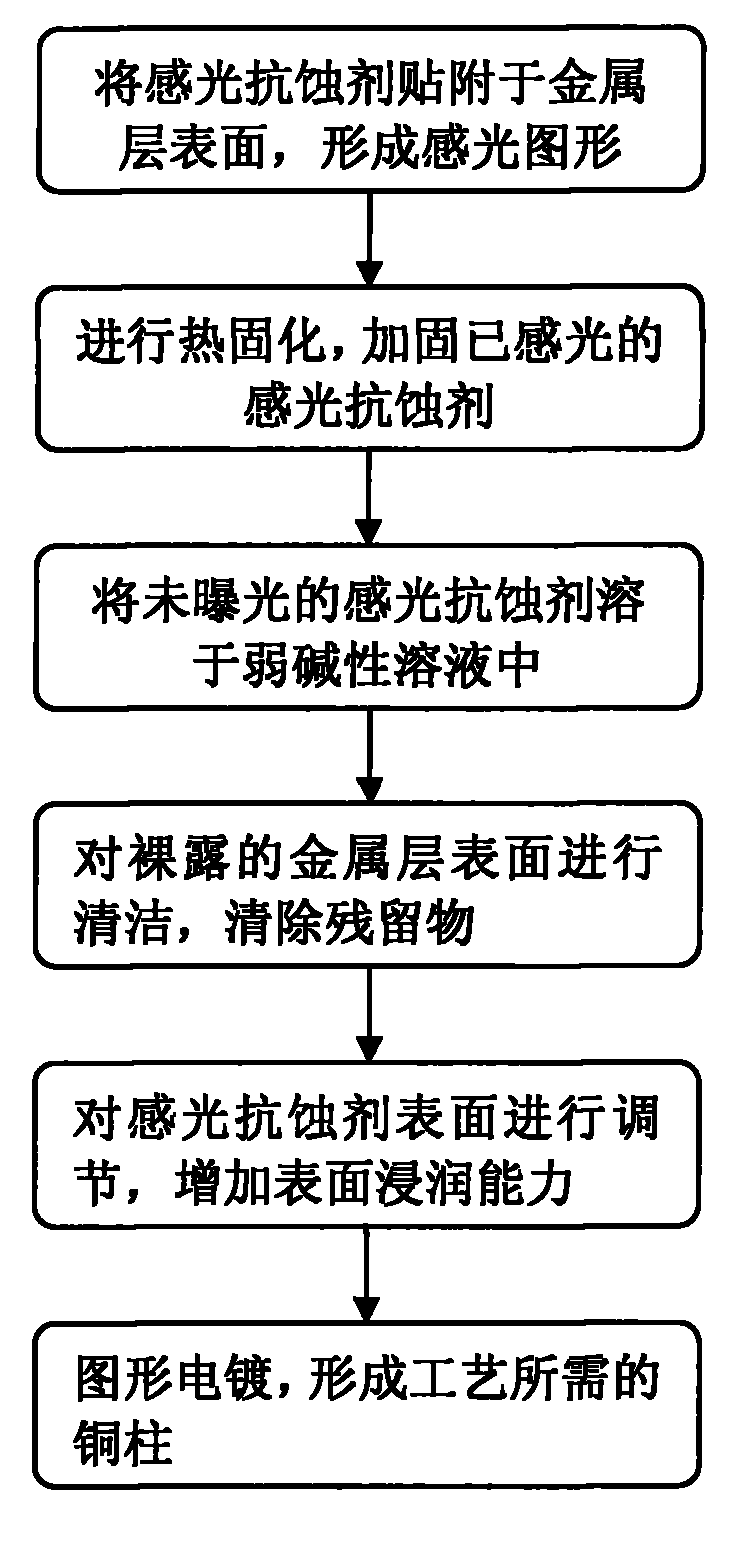

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0025] The main purpose of the present invention is to solve the problem of connection and disconnection caused by electroplating leakage and poor combination of copper pillar and metal layer in the production of copper pillar pattern with dry film thickness higher than 75um. Of course, it is also applicable to the production of copper pillar patterns with a dry film thickness less than 75um.

[0026] The present invention adopts the following technical scheme: use heat curing to reinforce the photosensitive resist after photosensitive photoresist, increase the degree of polymerization of the photosensitive resist and the bonding force with the metal layer, pass the Plasma etching cleans the exposed metal layer and adjusts the wettability of the photoresist surface with the electroplating solution.

[0027] The main process steps are as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com