Assembly tool for printed circuit board of automobile instrument

A technology of printed circuit boards and assembly tooling, which is applied in the field of machinery, can solve problems such as appearance defects of automobile instruments, achieve the effects of reducing manpower consumption and injuries, facilitating removal, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

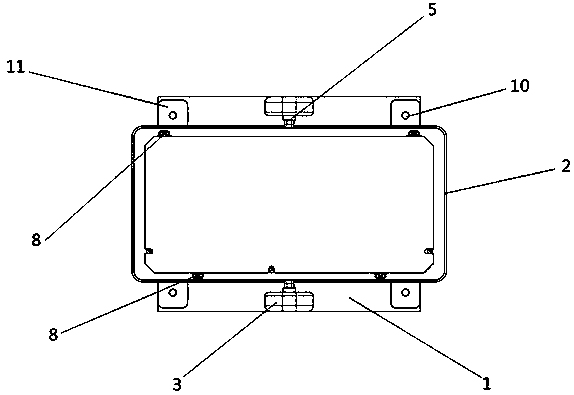

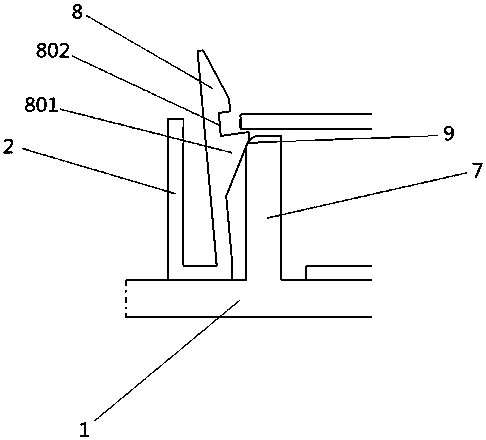

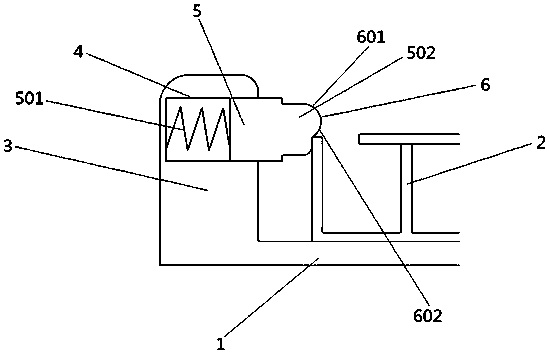

[0013] Such as Figure 1 to Figure 3 As shown, this automobile instrument printed circuit board assembly tooling of the present invention includes a rectangular base 1 and a light box frame 2, and two elastic briquetting seats 3 are fixedly arranged in the middle of the upper and lower sides of the rectangular pedestal 1, and the two elastic briquetting seats 3. The spacing is greater than the width of the light box frame 2. A chute 4 is horizontally arranged at the top of the elastic briquetting block seat 3. The opening of the chute 4 is inward. The elastic briquetting block 5 is horizontally arranged in the chute 4. The pressure block 502 is composed of a compression spring 501 placed in the chute 4, one end is connected to the bottom of the chute 4, the other end is connected to the pressure block 502, the head of the pressure block 502 extends out of the chute 4, and the other end is connected to the compression spring 501. The upper half of the head of the briquetting bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com