Reinforcing plate for bottom plate of vehicle

A technology for strengthening the floor and reinforcing plates, which is applied to vehicle components, upper structures, and sub-assemblies of the upper structure, etc., which can solve the problems of rising vehicle body costs, heavier vehicle weight, and inconspicuous stiffness improvement, and achieve weight saving, increased stiffness, and The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

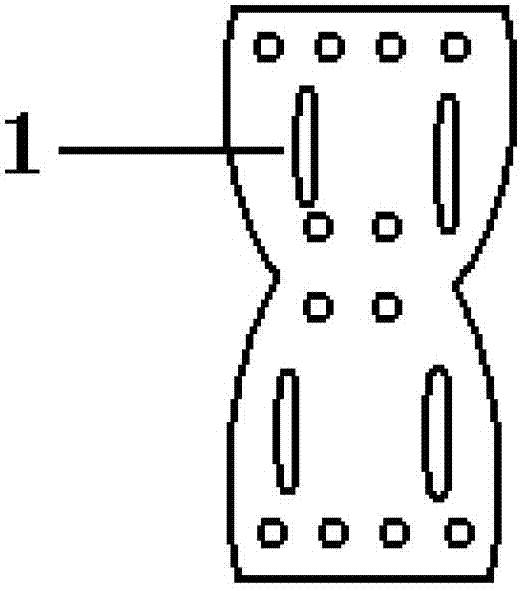

[0017] Such as figure 1 As shown, the technical solution provided by the present invention is a kind of automobile floor reinforcement plate, including a thin waist type reinforcement plate 1, and the thin waist type reinforcement plate 1 is arranged on the upper part of the front floor of the vehicle body and the rear floor of the vehicle body. The waist reinforcement plate 1 is fixedly connected with the front floor of the vehicle body and the rear floor of the vehicle body respectively.

[0018] The waist-thin reinforcing plate 1 is made of high-strength density board, and the thickness of the waist-thin reinforcing plate 1 is 3-5 mm.

[0019] The thickness of the waist-thin reinforcing plate 1 is 4mm. .

[0020] The waist-thin reinforcing plate 1 is formed into a waist-thin shape, and the width at both ends of the waist-thin reinforcing plate 1 is greater than the width at the middle of the waist-thin reinforcing plate 1 .

[0021] The waist-thin reinforcing plate 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com