Improved graphite purification furnace

A graphite purification furnace and furnace body technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of high cost, complex structure, large energy consumption and loss, etc., achieve simple structure, ensure purification effect, and seal performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

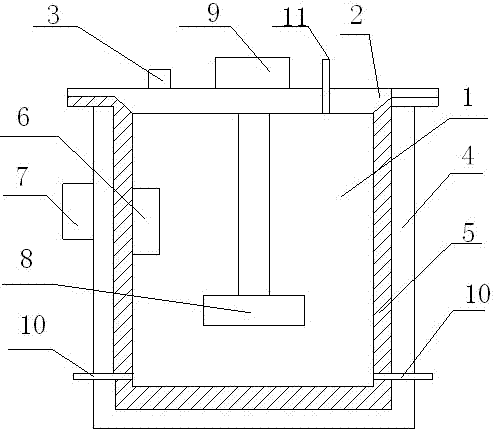

[0012] Such as figure 1 Shown, the improved graphite purification furnace of the present invention comprises furnace body 1, loam cake 2, and loam cake 2 is provided with feed inlet 3, and the outer surface of furnace body 1 is provided with one deck temperature-regulating layer 4, and the temperature-regulating layer 4 The inner side is provided with an insulating layer 5, a heater 6 is provided on the inner wall of the furnace body 1, and the heater 6 is connected to a heating controller 7. A stirring device 8 is provided inside the furnace body 1, and the stirring device 8 and the motor 9 arranged on the upper cover 2 Connected, the lower end of the furnace body 1 is provided with an air delivery hole 10, and the upper cover 2 is provided with an air extraction hole 11.

[0013] In the improved graphite purification furnace of the present invention, a heater 6 is provided on the inner wall of the body of furnace 1, and the heater 6 is connected to a heating controller 7. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com