Online vibration control tilting-pad radial sliding bearing device

A radial sliding and vibration control technology, applied in the direction of sliding contact bearings, etc., can solve the problems of severe vibration, oil film oscillation, etc., and achieve the effect of suppressing vibration and even unstable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

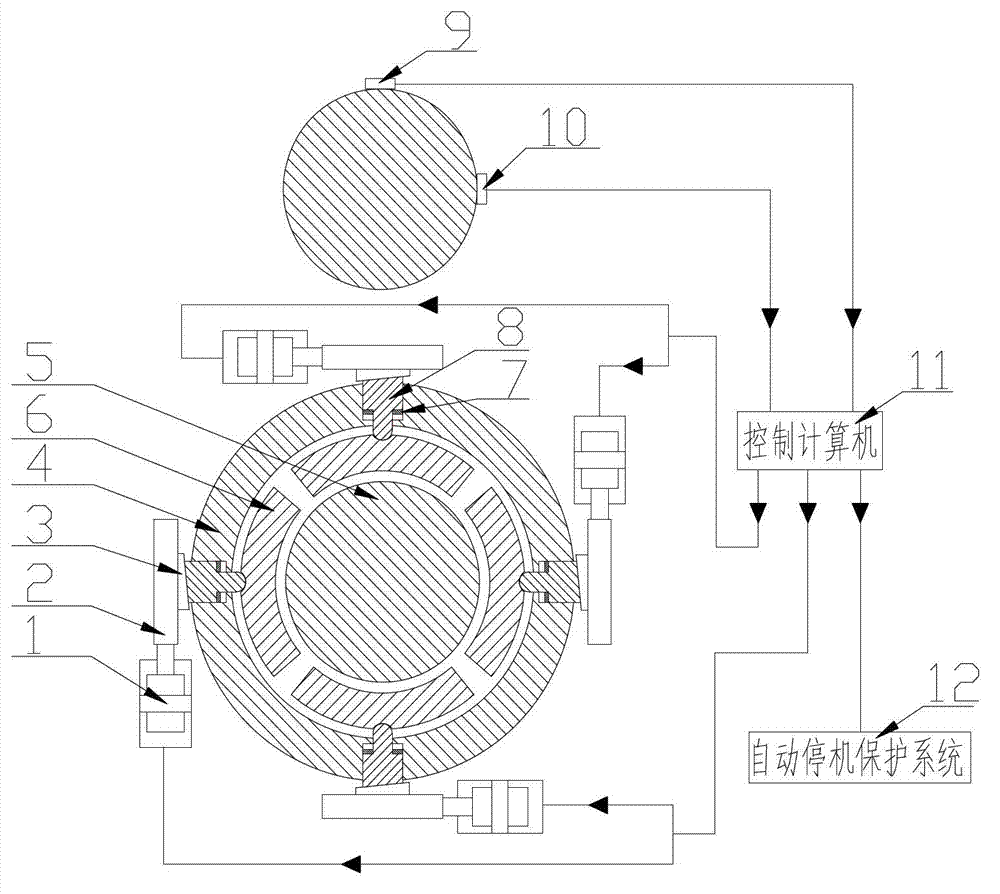

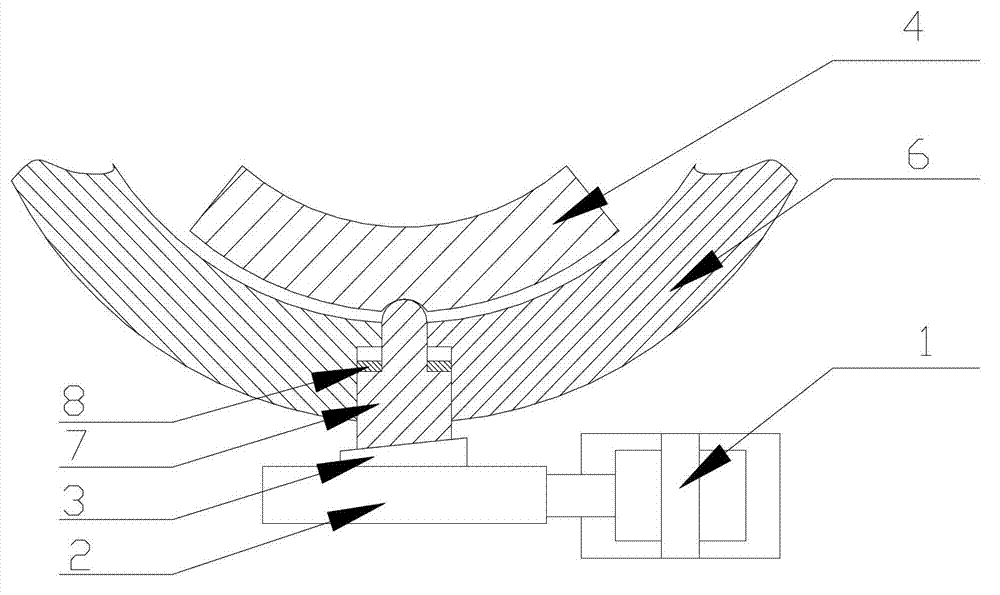

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

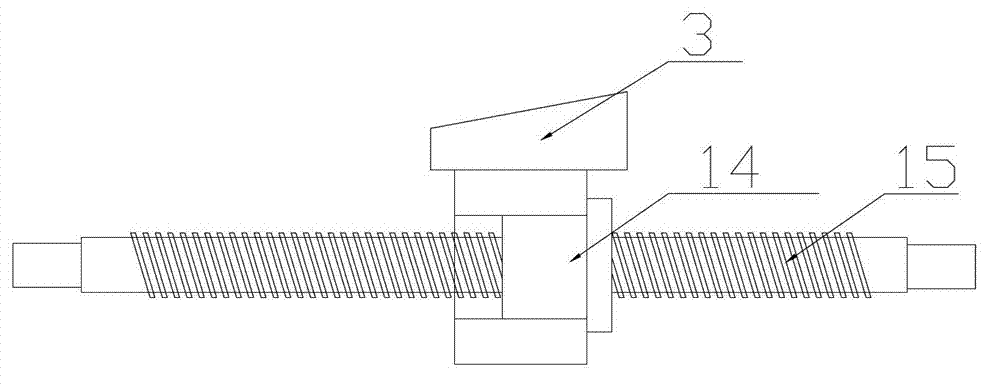

[0024] see Figure 1 to Figure 3 As shown, the present invention is a tilting pad radial sliding bearing device with online vibration control, which includes four parts: a radial tilting pad sliding bearing with adjustable state, a detection unit, a control unit and an actuator; the state is adjustable The tilting pad radial sliding bearing includes radially adjustable tilting pads 6 installed on the bearing housing 4 at equal intervals. The specific number of radially adjustable tilting pads 6 can be determined according to actual needs. The back of the adjustable tiltable pad 6 is connected to the support block 8, and the support 8 is connected to the lead screw nut 14 through the wedge block 3; the detection unit includes a first vibration sensor 9 and a second vibration sensor 10, the first The vibration sensor 9 and the second vibration sensor 10 are installed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com