Drive system for an electro-mechanical three-way dual seat valve

A double-seat valve and three-way technology, which is applied in the field of screw drive system for valve actuation, reciprocating three-way double-seat valve, and coolant valve, to eliminate seal leakage and seal wear, high fluid flow coefficient, and provide Effect of Fluid Flow Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

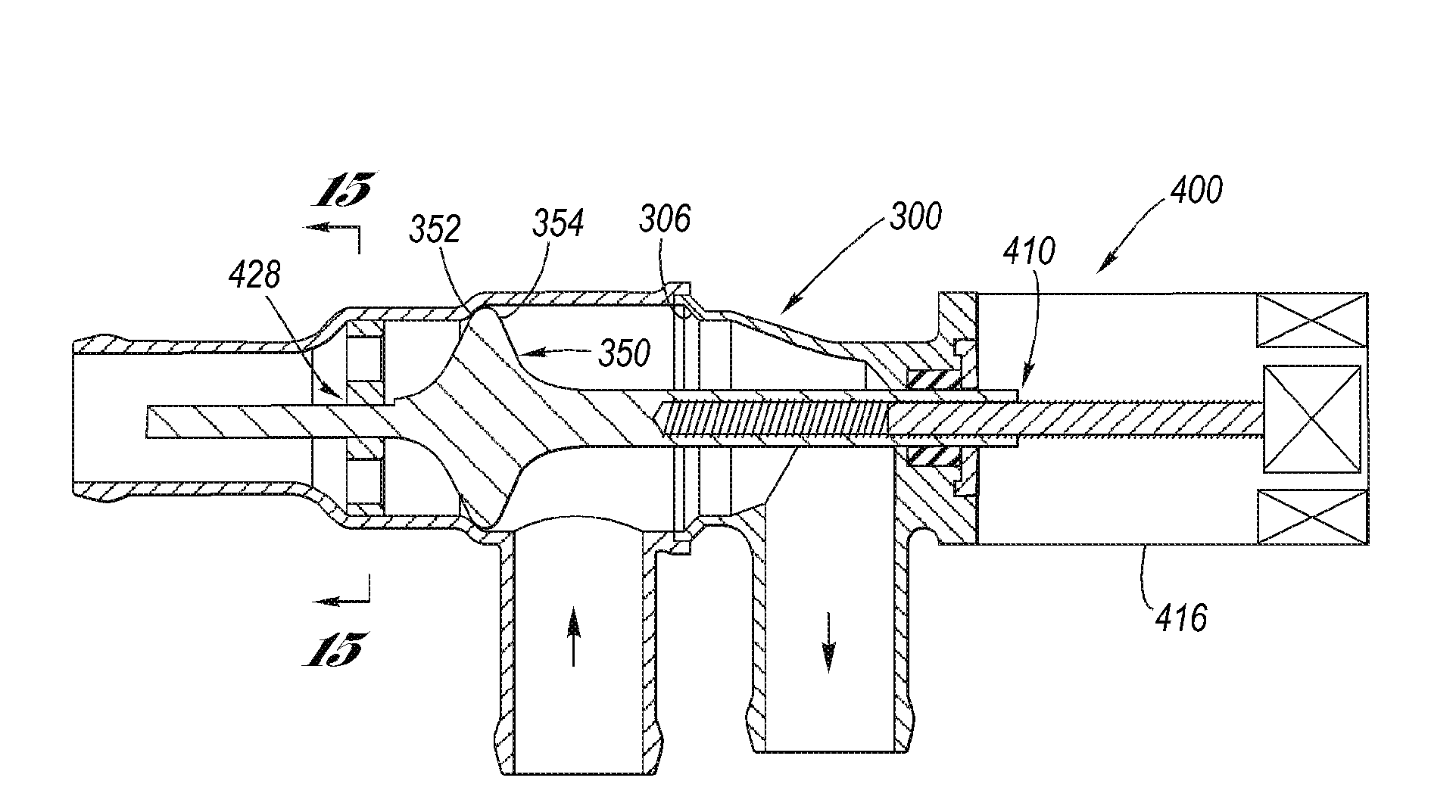

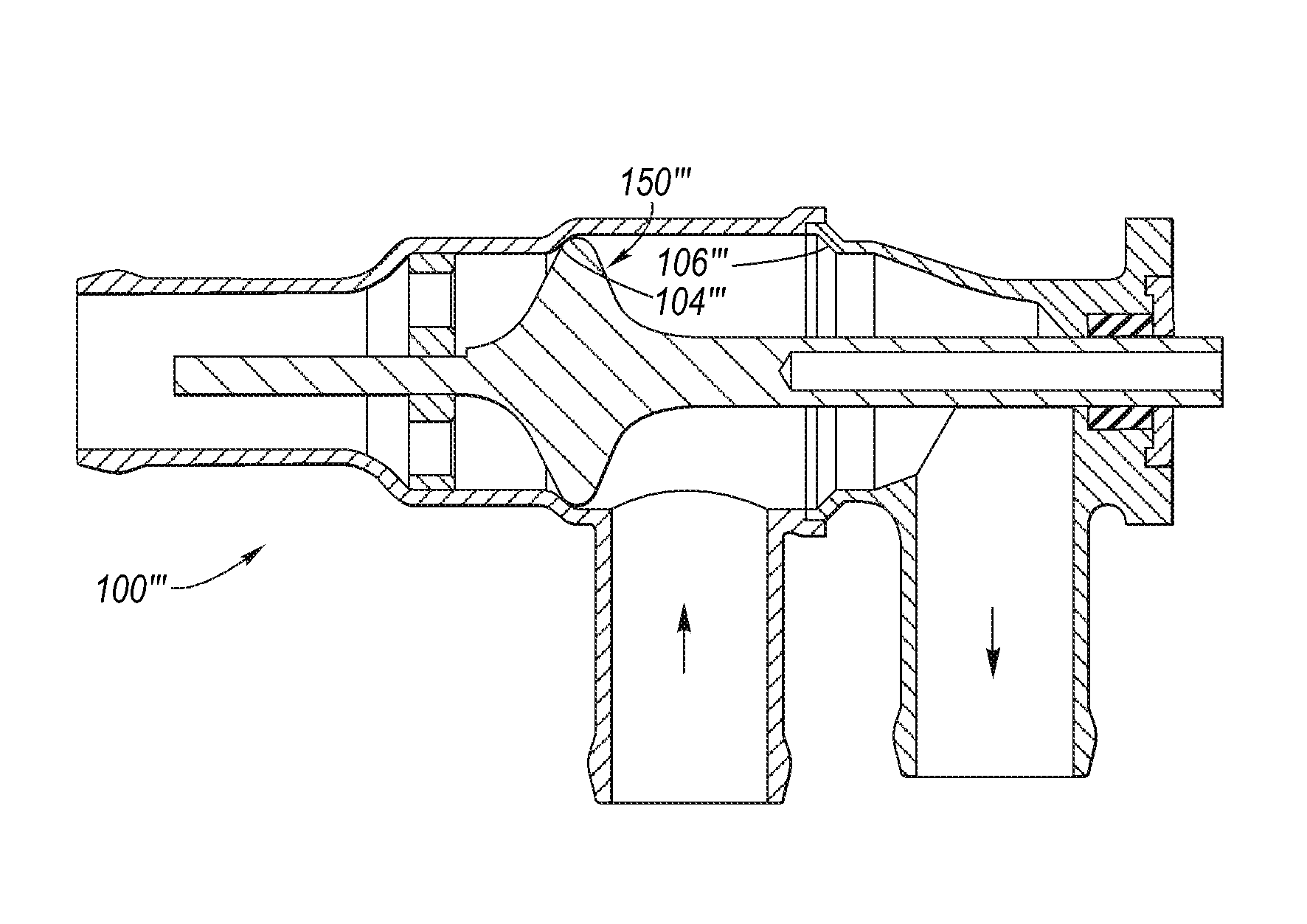

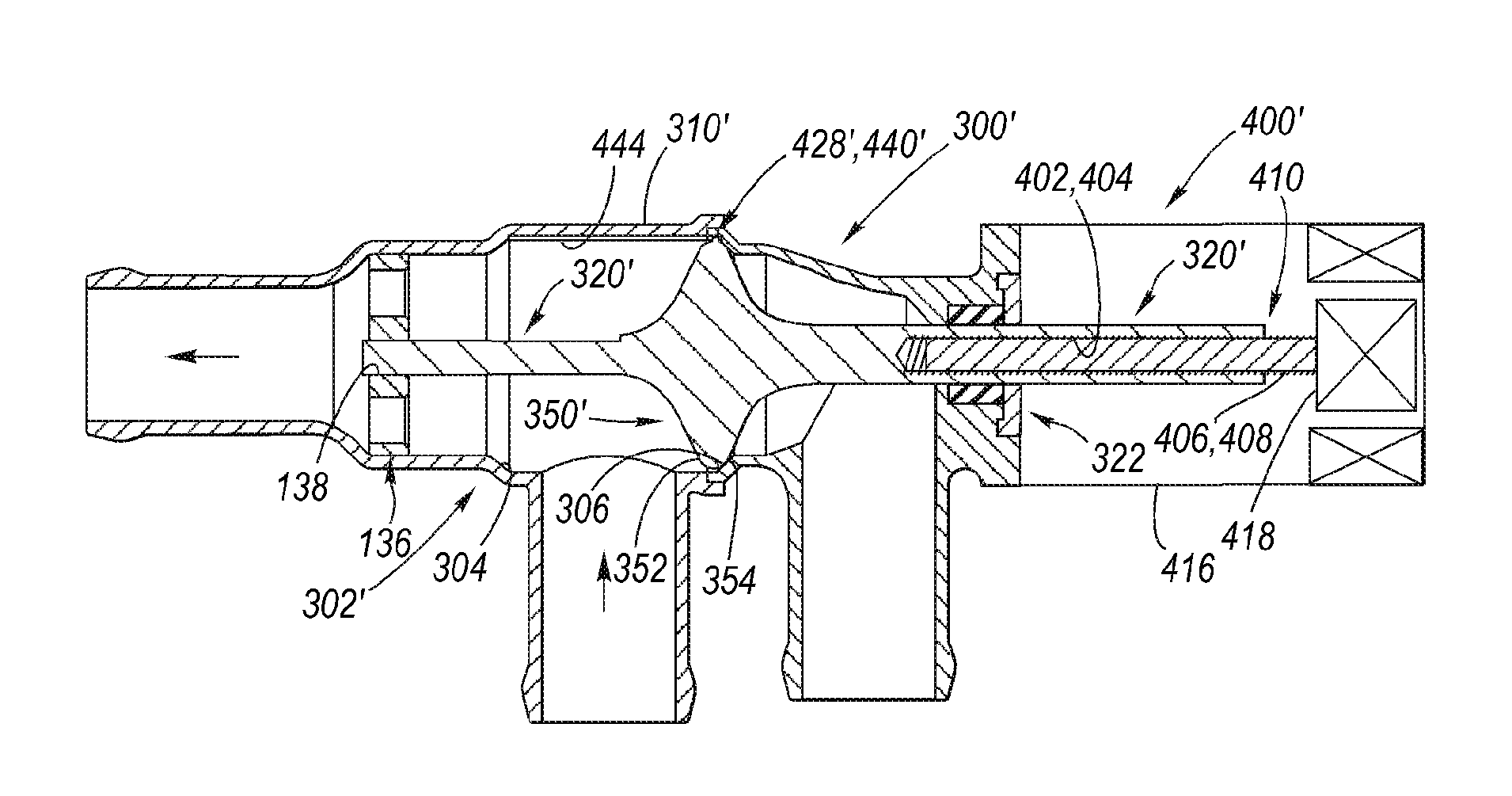

[0082] Referring now to the accompanying drawings, Figure 1 to Figure 12 Various exemplary aspects of the structure and function of a three-way double-seat valve are depicted, Figure 13 to Figure 21 Various exemplary aspects of a lead screw drive system according to the present invention for a three-way double-seat valve are depicted.

[0083] First refer to Figure 1 to Figure 12 , and now the three-way double-seat valve 100 will be described in detail. This Three-Way Dual Seat Valve 100 is described as "Electro-Mechanical Three-Way Dual Seat Valve" filed on November 1, 2011 by the applicant K.R. Kabel and assigned to its assignee US Patent Application Serial No. 13 / 286,452, the disclosure of which is incorporated herein by reference.

[0084] The three-way double-seat valve according to the present invention comprises a valve body 102; for manufacturing purposes, the valve body 102 is composed of first and second valve body parts 102', 102'', the first and second valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com