Production management method and system for executing the method

A production management system and production management technology, applied in the field of the system that implements the method, can solve the problems that EPCIS cannot meet the requirements of interrupt management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

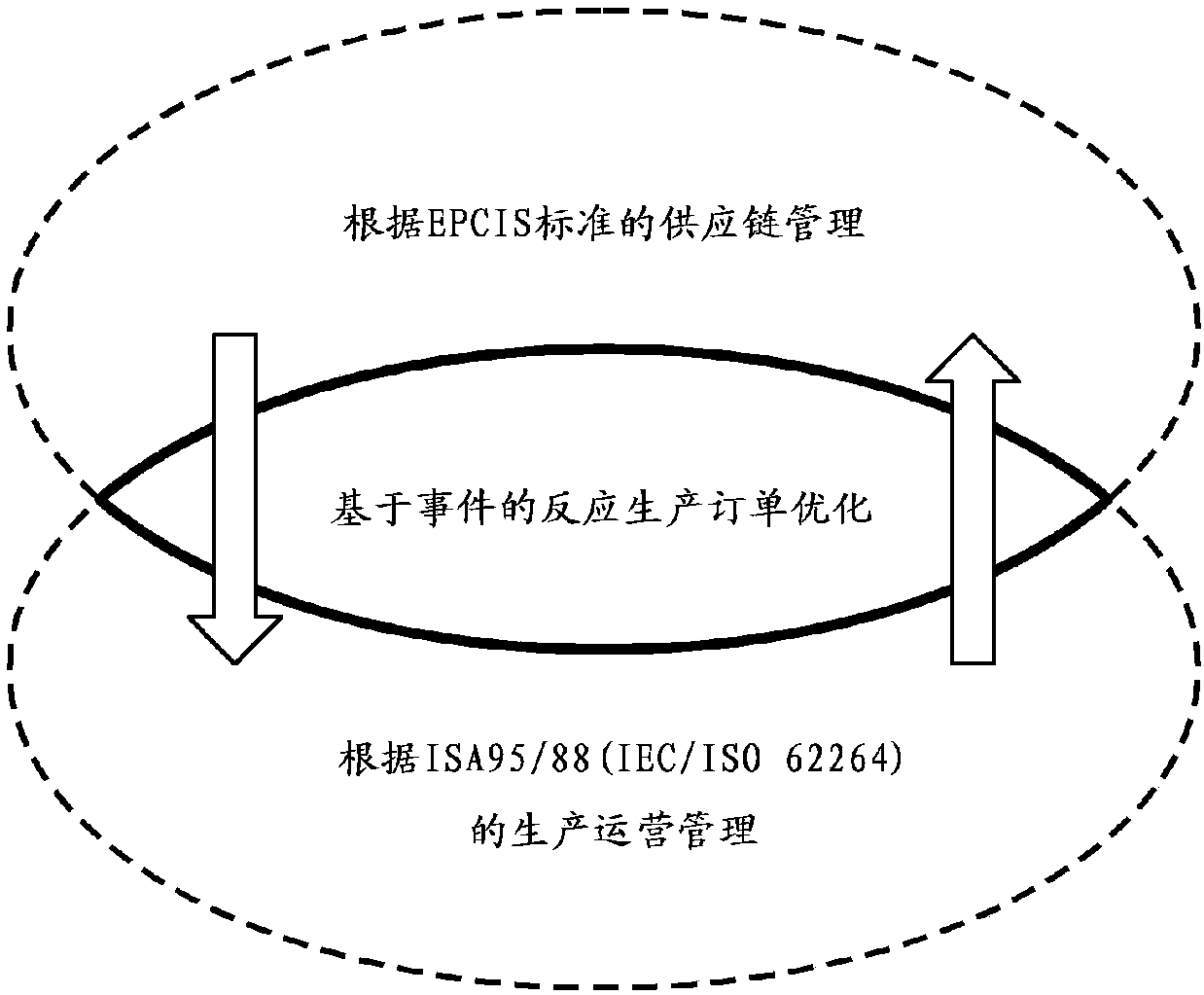

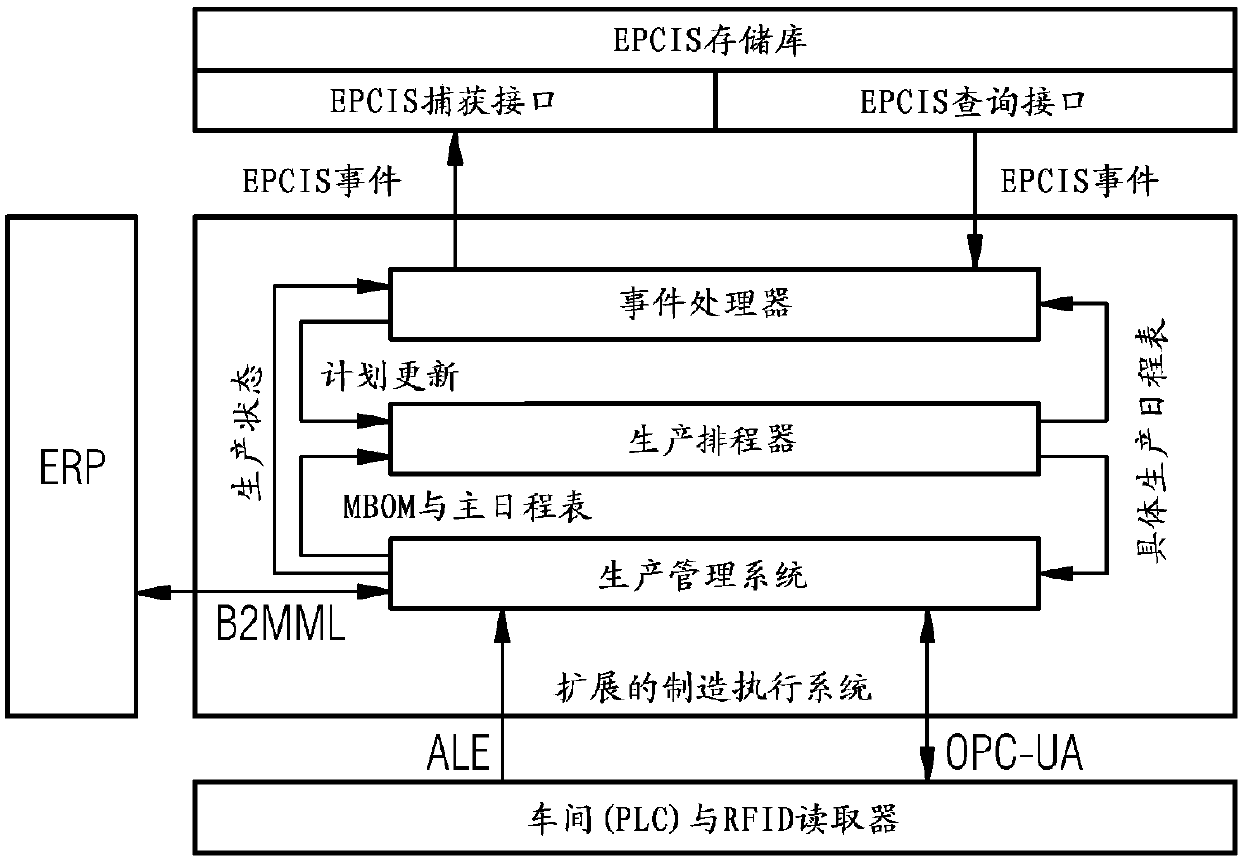

[0058] figure 1 The position of the proposed event-based reactive production order optimization method at the intersection of supply management according to the EPCIS standard [4] and production operations management according to ISA95 / 88 [1], [2] is shown. The proposed architecture seamlessly integrates cross-company track & trace functionality with the company's manufacturing operations management. To enable short-term reactions to critical disruptions, the Manufacturing Execution System is extended with EPCIS-compliant event-handling mechanisms that support the identification of critical situations in the supply chain and trigger appropriate production rescheduling.

[0059] 1. Overall system architecture

[0060] refer to figure 2 . The overall structure includes:

[0061] i) a central component for the exchange of object tracking information by multiple companies along the supply chain, and

[0062] ii) A collection of distributed components that depend on this info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com