Laminating device and laminating method of U-shaped laminated busbar

A technology of laminated busbars and pressing devices, applied in the electrical field, can solve problems such as reducing product safety performance, increasing production costs, and poor bending, so as to avoid poor bending, improve work efficiency, and avoid bending errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

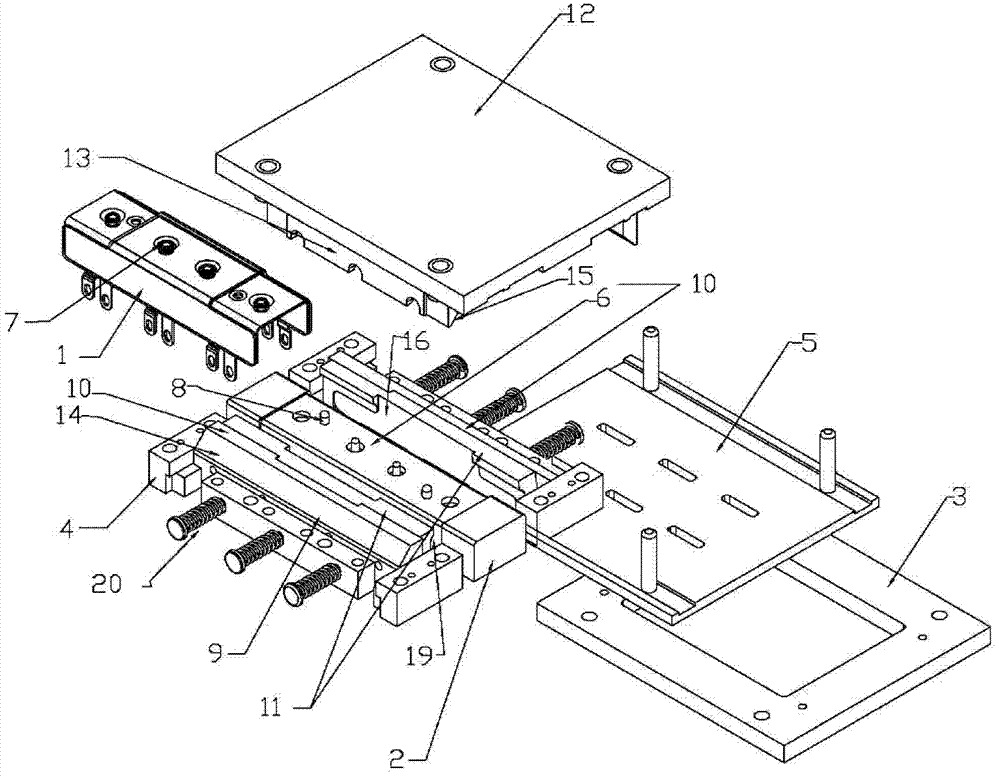

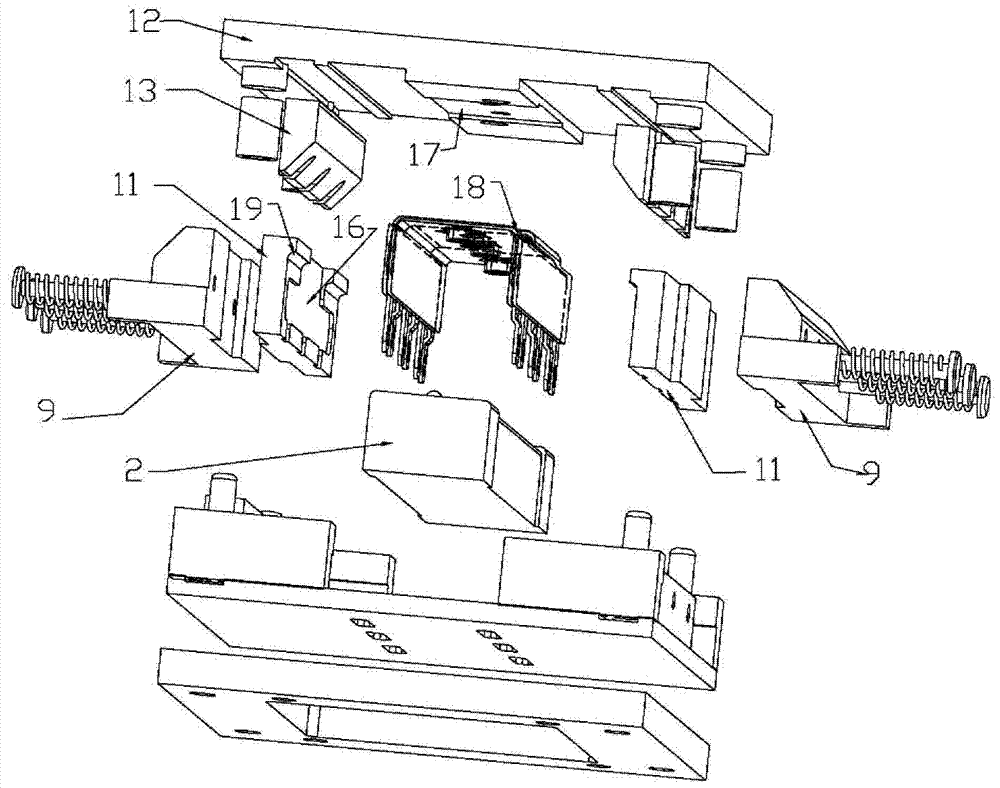

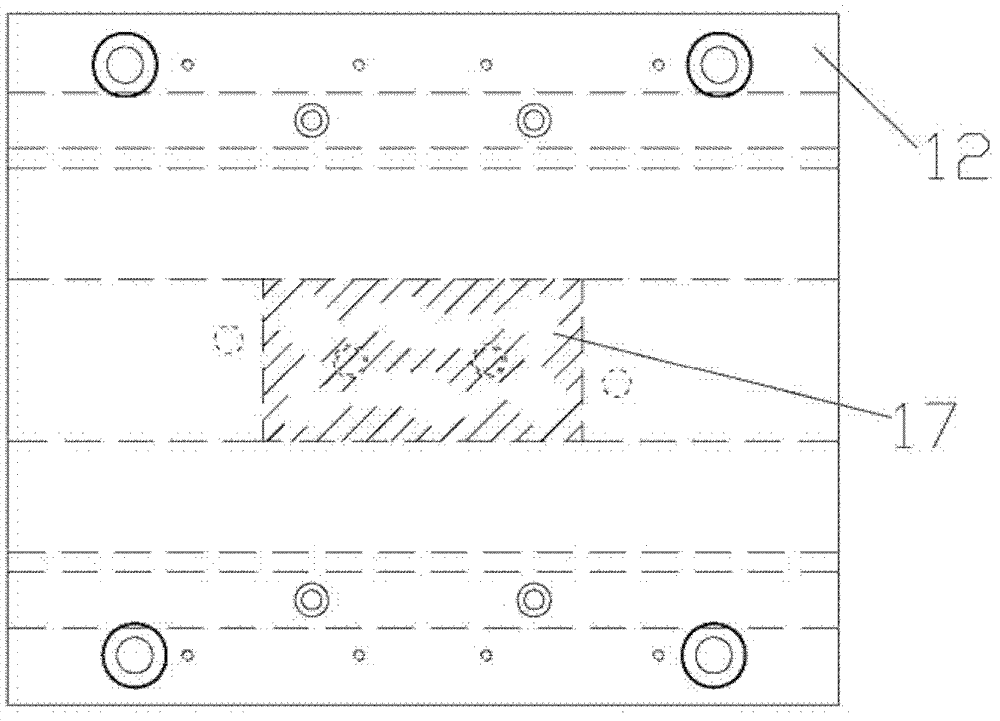

[0037] refer to figure 1 and figure 2 , the pressing device of the U-shaped laminated busbar in the embodiment of the present invention mainly performs the pressing work on the U-shaped laminated busbar 1 to be pressed, and the laminated busbar 1 to be pressed is composed of copper bars of each layer and insulation Formed by paper combination, the size of the insulating paper is slightly larger than the size of the copper bar, so that each layer of insulating paper can be pressed together during edge sealing. The above pressing device mainly includes:

[0038] It is used to fix the U-shaped fixed seat of the laminated busbar 1 to be pressed, and the fixed seat is provided with a strip-shaped support fixture 2 for covering and supporting the laminated busbar 1 to be pressed, wherein the fixed seat includes The base 3, and the support mold 5 fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com