Roof structure with airflow channel

A roof structure and airflow channel technology, applied in building roofs, roof ventilation, ventilation systems, etc., can solve the problems of large-area bulging, cracking, and rain leakage on the roof, achieve good rain leakage prevention effect, promote internal and external exchange, prevent The effect of gas expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

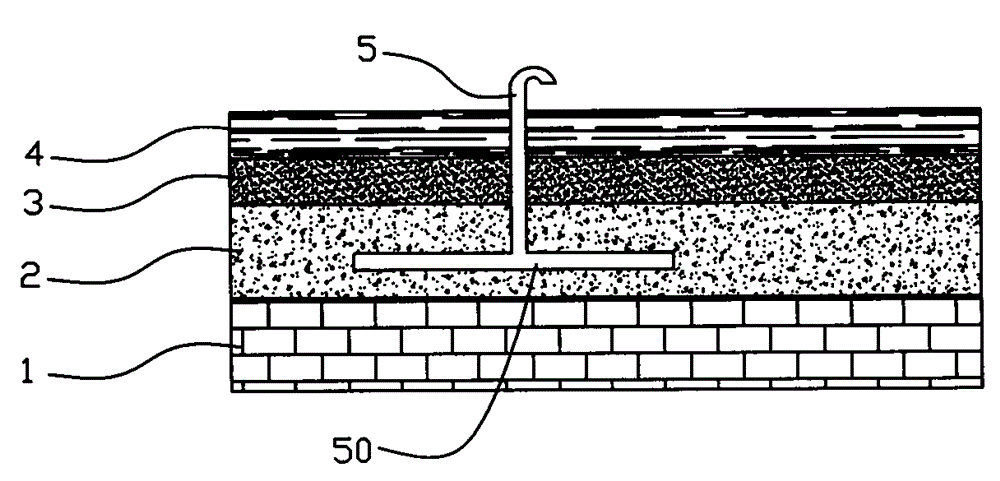

[0013] figure 1 Schematically shows the cross-sectional structure of the preferred embodiment of the present invention, as shown in the figure, the preferred embodiment includes a prefabricated slab layer 1, a carbon residue layer 2, a cement layer 3 and an asphalt felt layer 4 arranged sequentially from bottom to top, In order to make the gas in the carbon slag layer 2 communicate with the outside, this preferred embodiment also includes a vertically arranged air duct 5, and the lower end of the air duct 5 passes through the cement layer 3 and the asphalt felt layer 4 and extends into the carbon slag layer. 2, the upper end of the air duct 5 is bent downwards to prevent rainwater from entering the carbon slag layer 2.

[0014] If the air duct 4 is not set, for the roof that is not provided with the asphalt felt layer 4, the prefabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com