A kind of polyvinyl alcohol composite fresh-keeping film of anti-expansion bag and its preparation method and application

A polyvinyl alcohol and composite fresh-keeping technology, which is applied in the field of fresh-keeping film preparation, can solve problems such as bulging easily, and achieve the effects of preventing bulging, prolonging the permeation path, and accelerating internal and external exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In view of the problem that in the prior art, PVA is used for the packaging of fruits and vegetables with low barrier property requirements and is prone to swelling, the present invention provides a polyvinyl alcohol composite fresh-keeping film for anti-swelling bags and a preparation method thereof, so as to solve the problem of existing products. existing technical problems.

[0035] Specifically, the present invention uses PVA as the base material, and by introducing inorganic mesoporous silica nanoparticles and using synergistic antibacterial agents, a PVA composite fresh-keeping film with modified atmosphere and antibacterial functions is prepared. The preparation method can be referred to as follows:

[0036] (1) Preparation of mesoporous silica: add cetyltrimethylammonium bromide (CTAB) to deionized water, add sodium hydroxide (NaOH) to adjust pH; add 1,3,5-trimethylbenzene (TMB), stirring and dissolving, then adding ethyl orthosilicate (TEOS), heating up and co...

Embodiment 1

[0056] (1) Add 0.2g CTAB to 100mL deionized water, stir and dissolve at 800r / min, add NaOH to adjust pH=9.5, continue stirring at 80°C for 15min, then adjust the speed to 1600r / min, add 0.07mL TMB, stir for 30min Then 2 mL of TEOS was slowly added dropwise, and after stirring for 24 h, suction filtration, repeated washing with deionized water and absolute ethanol, and vacuum drying for 24 h were to obtain silicon oxide powder; the obtained sample was added to a mixture of 90 mL of absolute ethanol and 10 mL of hydrochloric acid. In the liquid, the temperature was raised to 90 °C and refluxed twice, and then filtered, washed and dried to obtain mesoporous silica;

[0057] (2) Add 0.6 g of mesoporous silica to 100 mL of deionized water, stir and disperse at room temperature for 30 min, then add 10 g of PVA (Model 117), raise the temperature to 80 °C and mechanically stir for 2 h, let stand overnight and scrape the film, and place at 50 °C. The PVA composite plastic wrap was obta...

Embodiment 2

[0067] The present embodiment 2 is basically the same as the embodiment 1, the difference is that an antibacterial agent is added in the step (2), and the specific method is:

[0068] (2) Add 0.6g of mesoporous silica to 100mL of deionized water, stir and disperse at room temperature for 30min, then add 10g of PVA (Model 117), heat up to 80°C and stir mechanically for 2h, add 0.06g of antibacterial agent, and continue to stir for 1h After standing overnight, the film was scraped, and dried at 50°C to obtain a PVA composite plastic wrap.

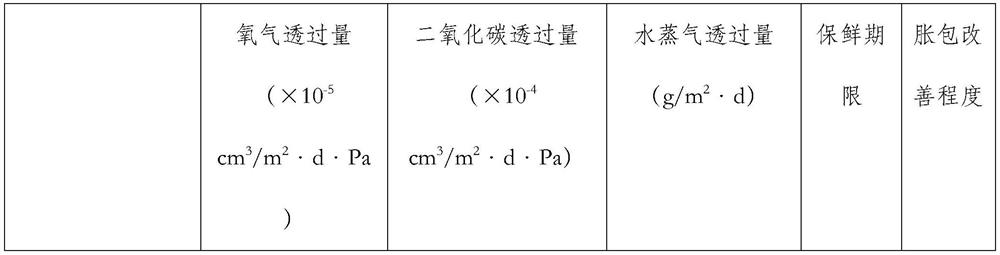

[0069] The added antibacterial agent types are shown in Table 2, the physical property indexes of the obtained PVA composite fresh-keeping film are measured and the fresh-keeping effect is tested, and the test results are shown in Table 2.

[0070] Table 2

[0071]

[0072] As can be seen from the data in Table 2, after adding the antibacterial agent, the fresh-keeping period of the blueberry is extended, and there is no obvious swelling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com