Rotation device for test tube scanning

A rotating device and test tube technology, applied in electromagnetic radiation induction and other directions, can solve the problems of heavy workload, easy leakage statistics, complex structure, etc., and achieve the effect of improving work efficiency, fast and continuous scanning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

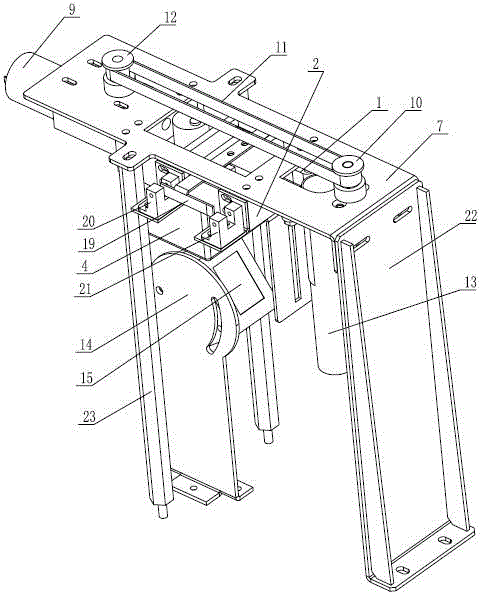

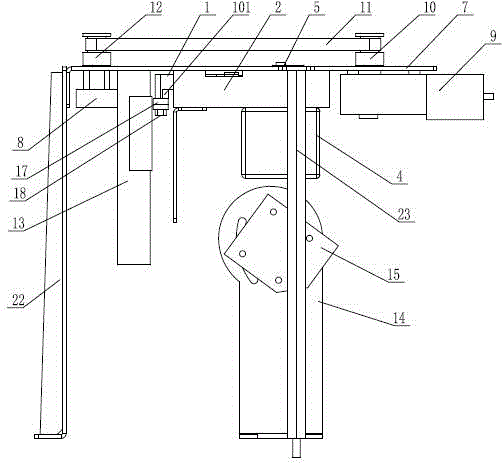

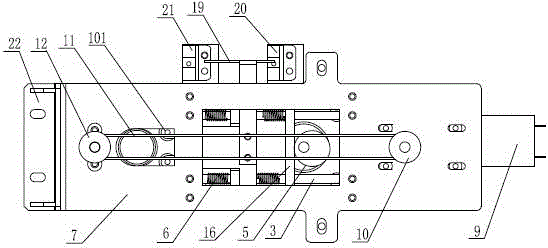

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0024] See figure 1 , figure 2 , image 3 , the present invention as figure 1 As shown, including clamping mechanism, rotating mechanism and scanner 15, wherein:

[0025] The clamping mechanism includes a clamping part 1, the front end of the clamping part 1 has a concave opening, and both sides of the concave opening are cylindrical clamping ends 101, and the cylindrical clamping end 101 includes a bearing 17, and the upper and lower two A bearing 17 is installed on the cylindrical hole of the head of the clamping part 1 through a pin 18, the clamping part 1 is slidingly matched with the guide rod 3 in the base 2, the clamping motor 4 is installed on the base 2, and the clamping motor 4 The output shaft and the cam 5 are coaxially fixed, and the cam 5 pushes the clamping part 1 to move on the guide rod 3. A spring 6 is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com