Wind-turbine gear oil composition

A technology of gear oil and composition, applied in the field of wind power gear oil composition, can solve the problems of non-biodegradability, easy decomposition, poor compatibility, etc., achieve long service life, ensure normal operation, and inhibit pitting corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Wind power gear oil composition, its each component is distributed as follows by weight percentage:

[0020] Polyalphaolefin 40: 80%, polyalphaolefin 8: 7.32%, polyol ester: 10%, sulfur phosphorus nitrogen compound extreme pressure antiwear agent: 1.8%, phenolic antioxidant: 0.3%, amine antioxidant : 0.4%, nonylamine phosphate mixture: 0.1%, benzotriazole derivatives: 0.05%, polyether anti-emulsifier: 0.03%.

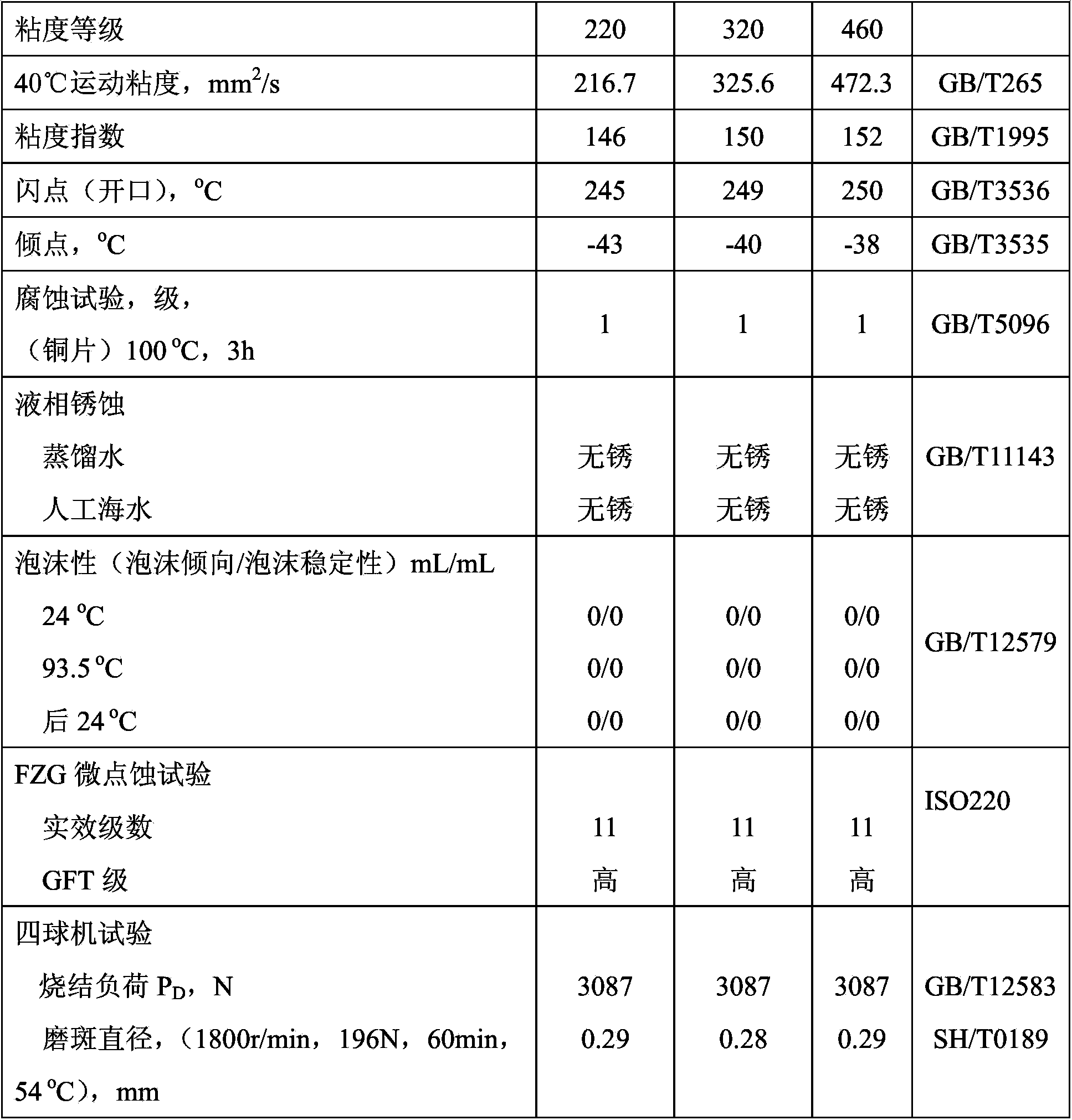

[0021] The main test performance is shown in Table 1.

Embodiment 2

[0023] Wind power gear oil composition, its each component is distributed as follows by weight percentage:

[0024] Polyalphaolefin 100: 17.32%, polyalphaolefin 40: 70%, polyol ester: 10%, sulfur phosphorus nitrogen compound extreme pressure antiwear agent: 1.8%, phenolic antioxidant: 0.3%, amine antioxidant : 0.4%, nonylamine phosphate mixture: 0.1%, benzotriazole derivatives: 0.05%, polyether anti-emulsifier: 0.03%. The main test performance is shown in Table 1.

Embodiment 3

[0026] Wind power gear oil composition, its each component is distributed as follows by weight percentage:

[0027] Polyalphaolefin 100: 55%, polyalphaolefin 40: 32.32%, polyol ester: 10%, sulfur phosphorus nitrogen compound extreme pressure antiwear agent: 1.8%, phenolic antioxidant: 0.3%, amine antioxidant : 0.4%, nonylamine phosphate mixture: 0.1%, benzotriazole derivatives: 0.05%, polyether anti-emulsifier: 0.03%. The main test performance is shown in Table 1.

[0028] Each embodiment performance test data of table 1

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com