A kind of antiwear wind power gear oil and preparation method thereof

A gear oil and wind power technology, applied in the petroleum industry, lubricating compositions, etc., can solve practical constraints, reduce friction and wear of metal friction pairs, etc., achieve long service life, inhibit pitting corrosion, and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

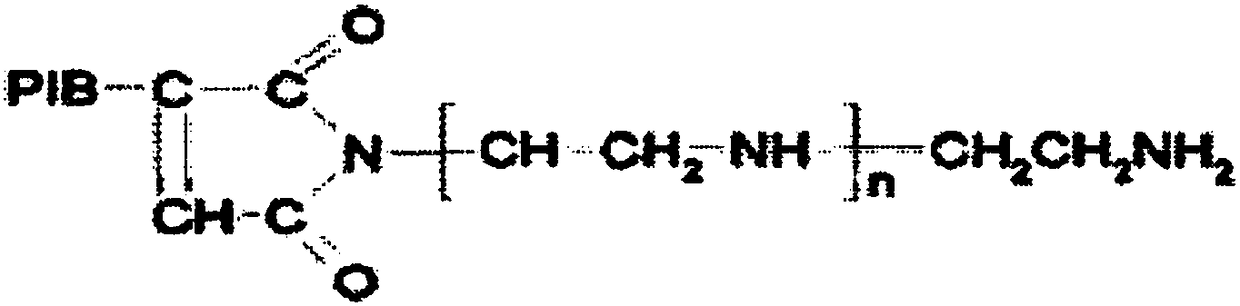

[0030] Anti-wear wind power gear oil raw materials (parts by weight): 0.5 part of monoalkenyl succinimide, 0.2 part of calcium alkylbenzenesulfonate, 0.1 part of 4,4'-dioctyldiphenylamine, 0.1 part of 2,4-bis( 0.2 parts of dodecylthiomethyl)-6-methylphenol, 0.5 parts of antiwear agent, and 93 parts of base oil.

[0031] The base oil is composed of 9-decenyl-oleate, 1,2,4-benzenetricarboxylic acid tri(2-ethylhexyl) ester, 9-octadecenoic acid-13-dococenyl ester according to The mass ratio is 1:1:1 and obtained by stirring and mixing evenly.

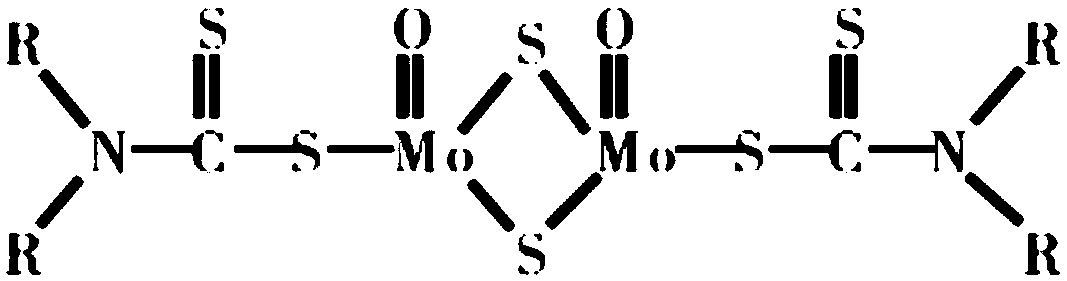

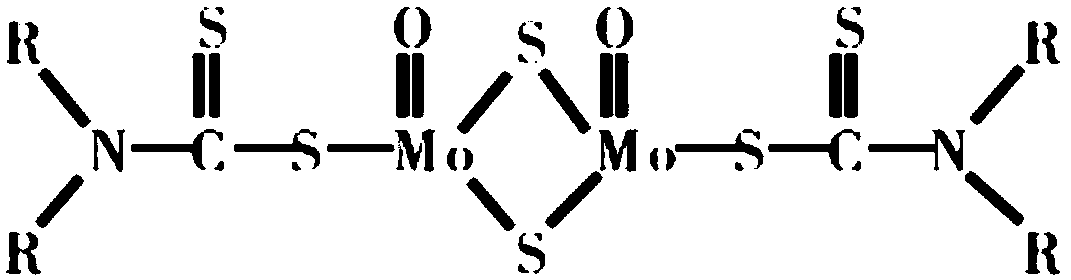

[0032] The anti-wear agent is composed of 50wt% N, N-di(2-ethylhexyl) molybdenum dithiocarbamate and 50wt% N, N-bis(tridecyl) molybdenum dithiocarbamate, and stir and mix uniformly get.

[0033] Preparation of anti-wear wind power gear oil:

[0034] Add one-half of the total weight of the base oil (that is, half of the total weight of the base oil) into the blending kettle, raise the temperature to 85°C, add 4,4'-dioctyl diphenylamine, 2...

Embodiment 2

[0036] It is basically the same as Example 1, the difference is only that: the base oil is composed of 1,2,4-benzenetricarboxylic acid tri(2-ethylhexyl) ester, 9-octadecenoic acid-13-dococenyl ester Stir and mix uniformly according to the mass ratio of 1:1. Obtain the antiwear wind power gear oil of embodiment 2.

Embodiment 3

[0038] Basically the same as Example 1, the only difference is that the base oil is stirred and mixed with 9-decenyl-oleate and 9-octadecenoic acid-13-dococenyl ester in a mass ratio of 1:1 Get even. Obtain the antiwear wind power gear oil of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com