Lubricating grease for blaster head bearing of shot blasting machine

A technology of lubricating grease and shot blasting machine, which is applied in the field of lubricating grease, can solve problems such as insufficient bearing life, grease failure, and temperature rise of the bearing of the shot blasting machine head, and achieves increased holding capacity, reduced friction and wear, and good performance. The effect of pressure and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below by specific examples.

[0023] Each embodiment and comparative example preparation method:

[0024] Embodiment 1-8 and comparative example

[0025] Add the thickener and 40%-60% base oil into the reaction kettle, stir and heat to 210-220°C, keep the temperature constant for 8-12 minutes, cool down to 160-180°C, add antioxidant, cool down to 130-150°C Add extreme pressure anti-wear agent, add 10%-30% base oil to cool, continue to stir, add the remaining base oil, stir to cool down to below 90°C, add structure improver, stir and mix evenly. The composition is oil-pressed three times by a three-roller machine, and then filtered through a 100-mesh screen, and the finished product is packed in cans.

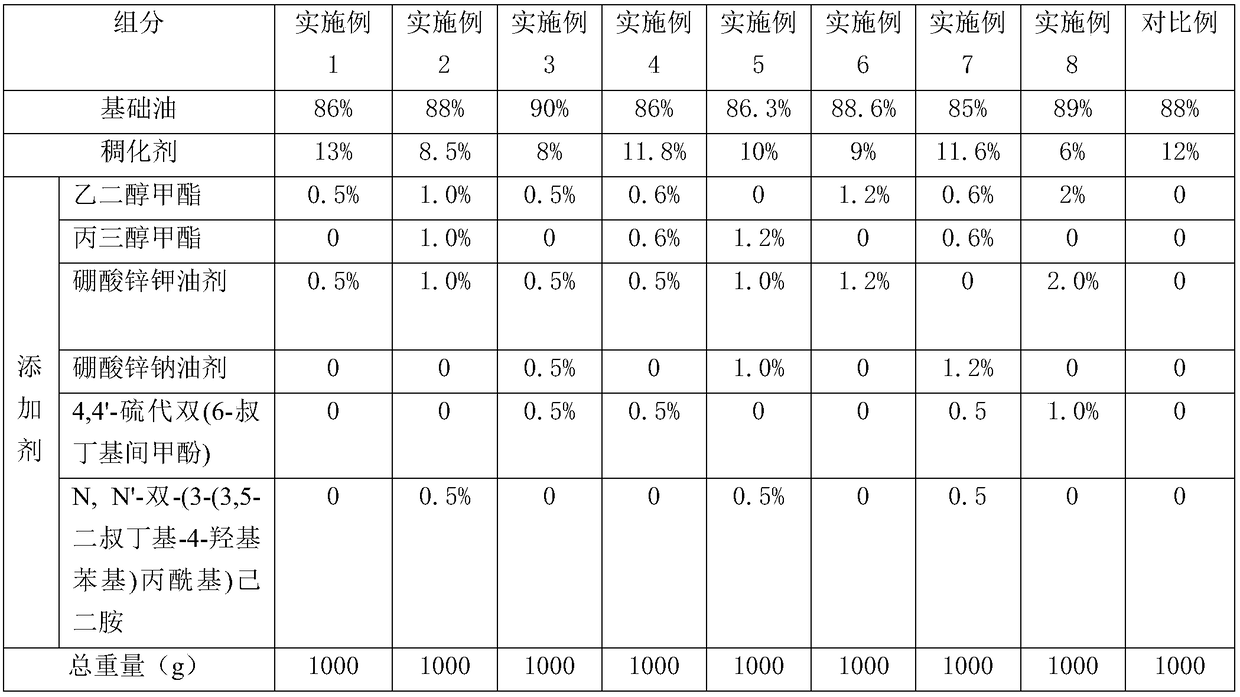

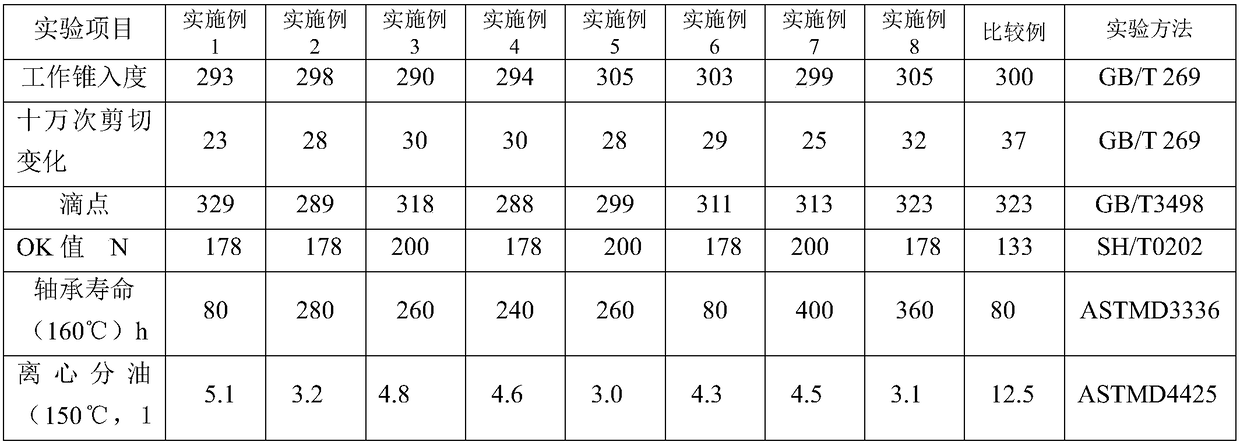

[0026] Embodiment 1-8 component content and comparative example component content are shown in Table 1

[0027] Table 1 embodiment 1-8 component content and comparative example component content

[0028]

[0029] Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com